Compressor preheating method, system, medium and equipment

A preheating and compressor technology, applied in the control system, ohmic resistance heating, electric heating devices, etc., can solve the problems of low preheating efficiency and unbalanced compressor preheating, so as to improve efficiency, reduce switching loss and reduce risk Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

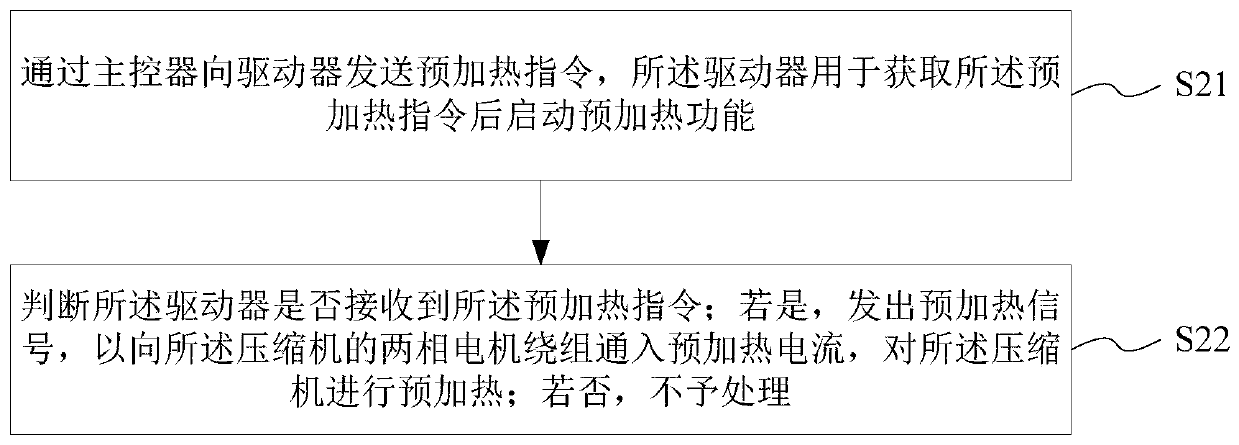

[0032] This embodiment provides a method for preheating a compressor, and the method for preheating a compressor includes:

[0033] sending a pre-heating instruction to the driver through the main controller, and the driver is used to start the pre-heating function after obtaining the pre-heating instruction;

[0034] judging whether the driver has received the preheating instruction;

[0035] If so, a preheating signal is sent to pass a preheating current to the two-phase motor winding of the compressor to preheat the compressor; if not, no processing is performed.

[0036] The method for preheating the compressor provided by this embodiment will be described in detail below with reference to the figures.

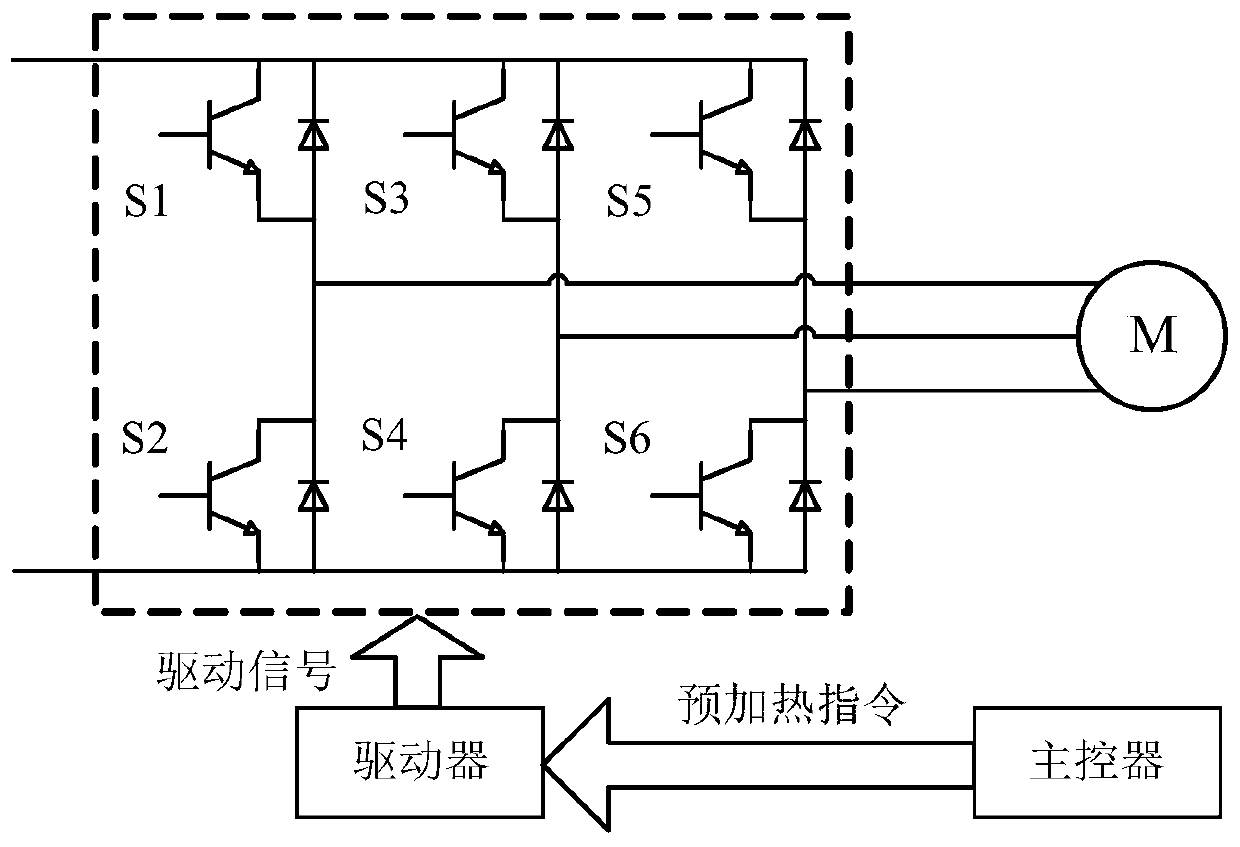

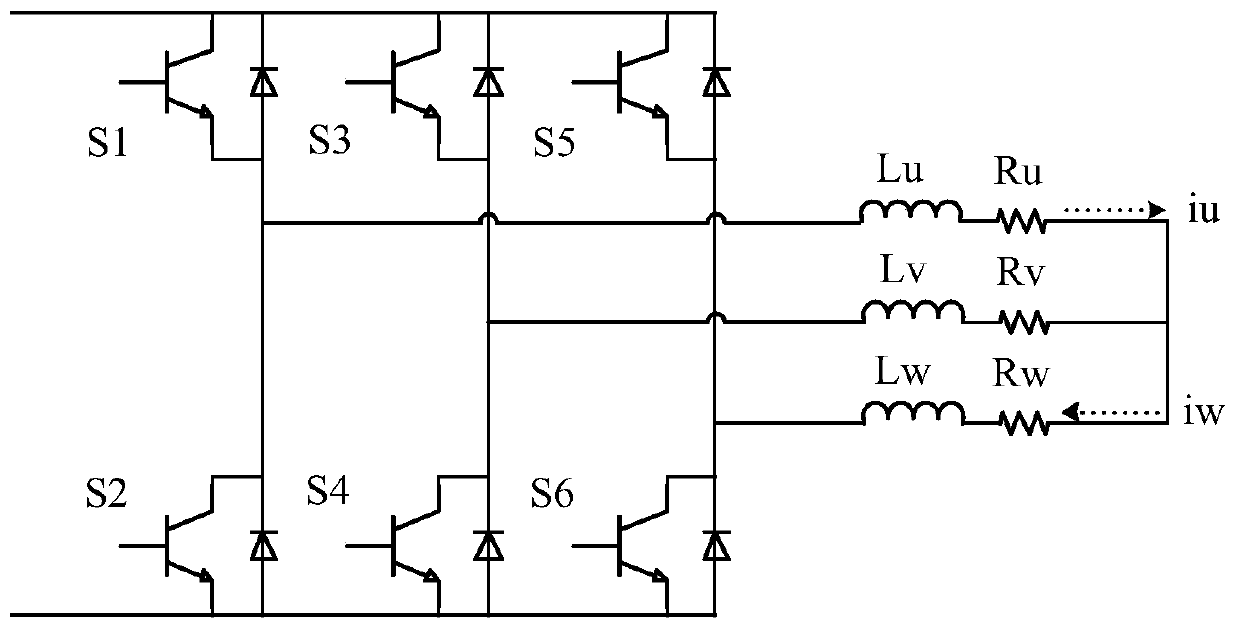

[0037] see figure 1 , shows a control block diagram of the compressor preheating mode in an embodiment of the compressor preheating method of the present invention. Such as figure 1 As shown, the compressor preheating method is applied to the control framework of the c...

Embodiment 2

[0058] This embodiment provides a compressor preheating system, the compressor preheating system includes:

[0059] The main control module is used to send a pre-heating instruction to the driver through the main controller, and the driver is used to start the pre-heating function after obtaining the pre-heating instruction;

[0060] The preheating module is used to determine whether the driver has received the preheating instruction; if so, send a preheating signal to pass a preheating current to the two-phase motor winding of the compressor to preheat the compressor. Heated; if not, discarded.

[0061] The preheating system of the compressor provided by this embodiment will be described in detail below with reference to the figures. It should be noted that it should be understood that the division of the various modules of the following systems is only a division of logical functions, and may be fully or partially integrated into a physical entity or physically separated du...

Embodiment 3

[0074] This embodiment provides a device, including: a processor, a memory, a transceiver, a communication interface or / and a system bus; the memory and the communication interface are connected to the processor and the transceiver through the system bus and complete mutual communication, and the memory is used for The computer program is stored, the communication interface is used to communicate with other devices, the processor and the transceiver are used to run the computer program, so that the device executes each step of the compressor preheating method.

[0075] Specifically, the device includes: a processor, a memory, a transceiver, a communication interface or / and a system bus; the memory and the communication interface are connected to the processor and the transceiver through the system bus and complete mutual communication, and the memory is used to store the The program, the communication interface are used to communicate with other devices, the processor and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com