Control system and control method for liquid level switch periodic tests in nuclear power plant and storage medium

A liquid level switch and control system technology, applied in the direction of nuclear power plant control, nuclear power plants, expert nuclear systems, etc., can solve the problems of DCS interlock protection function failure and high failure rate, and achieve the elimination of operation error risk, high reliability, The effect of reducing the interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

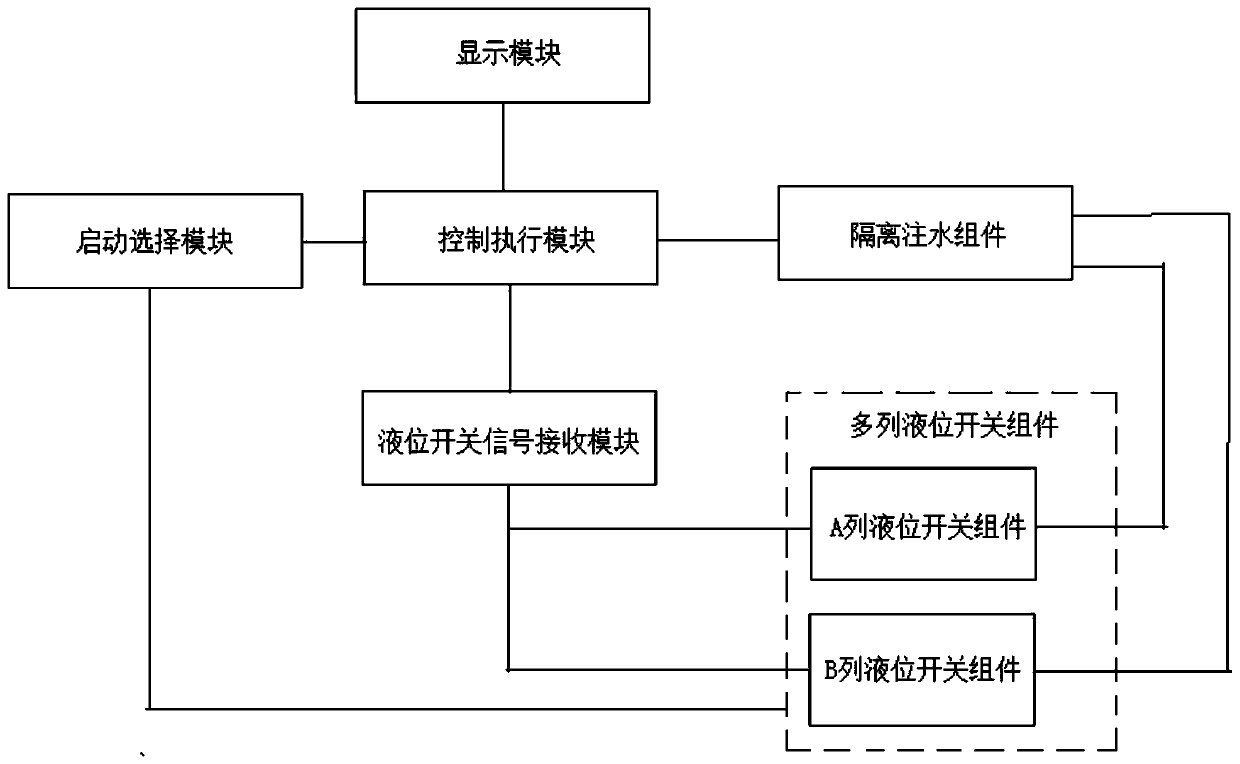

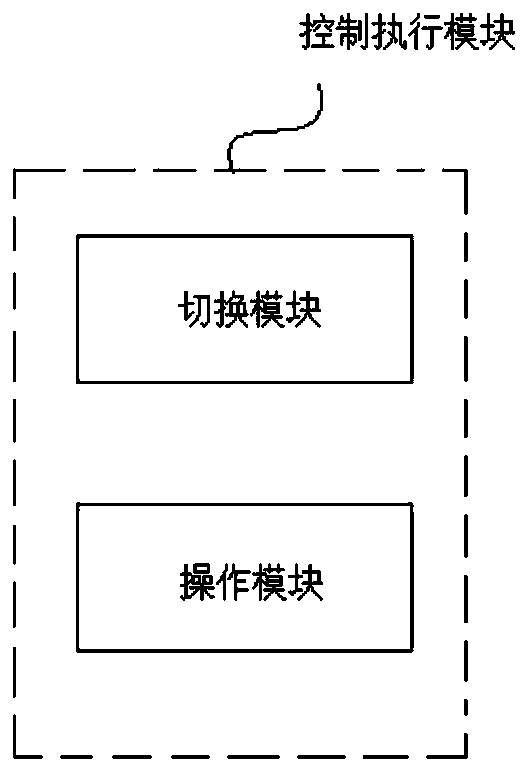

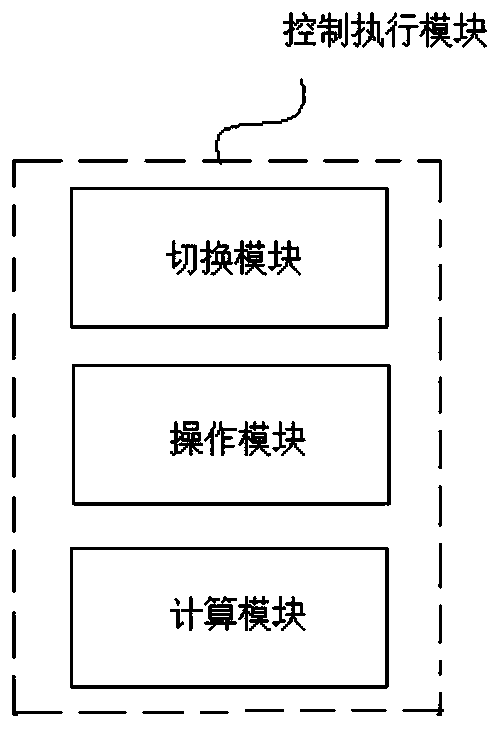

[0032] The embodiment of the present invention provides a control system for periodic testing of liquid level switches in nuclear power plants, see figure 1 , figure 1 It is a schematic diagram of the module structure of the control system in Embodiment 1 of the present invention. The control system includes: a start selection module, which is used to start the periodic test of the multi-row liquid level switch assembly and select the test row of the corresponding liquid level switch assembly to start the test; control execution Module, connected to the start selection module, used to cut off the selected test column from the DCS protection system, and operate the water injection isolation component corresponding to the selected test column; the liquid level switch signal receiving module, respectively connected to the control execution module and the liquid level The switch component is used to receive the liquid level signal of the test row where the liquid level switch comp...

Embodiment 2

[0047] The implementation of the present invention provides a control method for periodic tests of liquid level switches in nuclear power plants, which is applicable to the control system for periodic tests of liquid level switches in nuclear power plants shown in Embodiment 1, see Figure 10 , the method includes the following steps:

[0048] S100, start the periodic test of the multi-row liquid level switch assembly and select the test row corresponding to the liquid level switch assembly to start the test;

[0049] S200. Cut off the liquid level switch signal of one of the test columns obtained from the multi-row liquid level switch components from the DCS protection system, control the water injection isolation component of the test column, and isolate the liquid level switch component and the water tank of the test column Connect the connection between the liquid level switch assembly of the column to be tested and the water injection port for water injection operation; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com