Flexible gear and harmonic reducer with flexible gear and rigid gear

A technology of flexible splines and rigid splines, which is applied in the field of harmonic reducers, can solve the problems of weak load capacity of flexible splines and rigid splines, wear and tear of edge meshing points and sharp point meshing points, and short life, so as to facilitate the formation of oil film, Avoid serious tooth surface wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

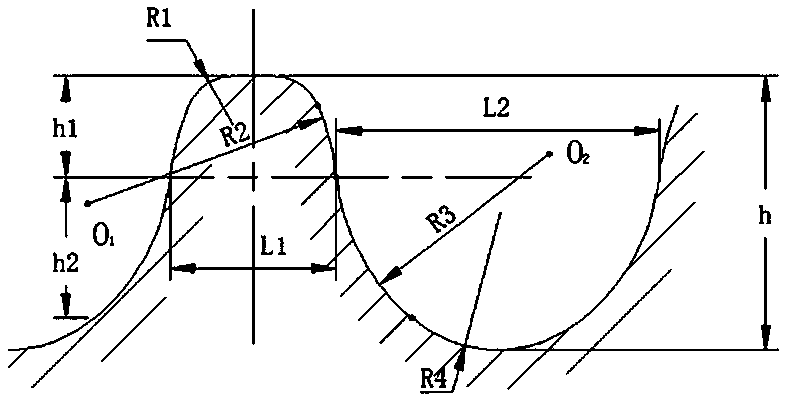

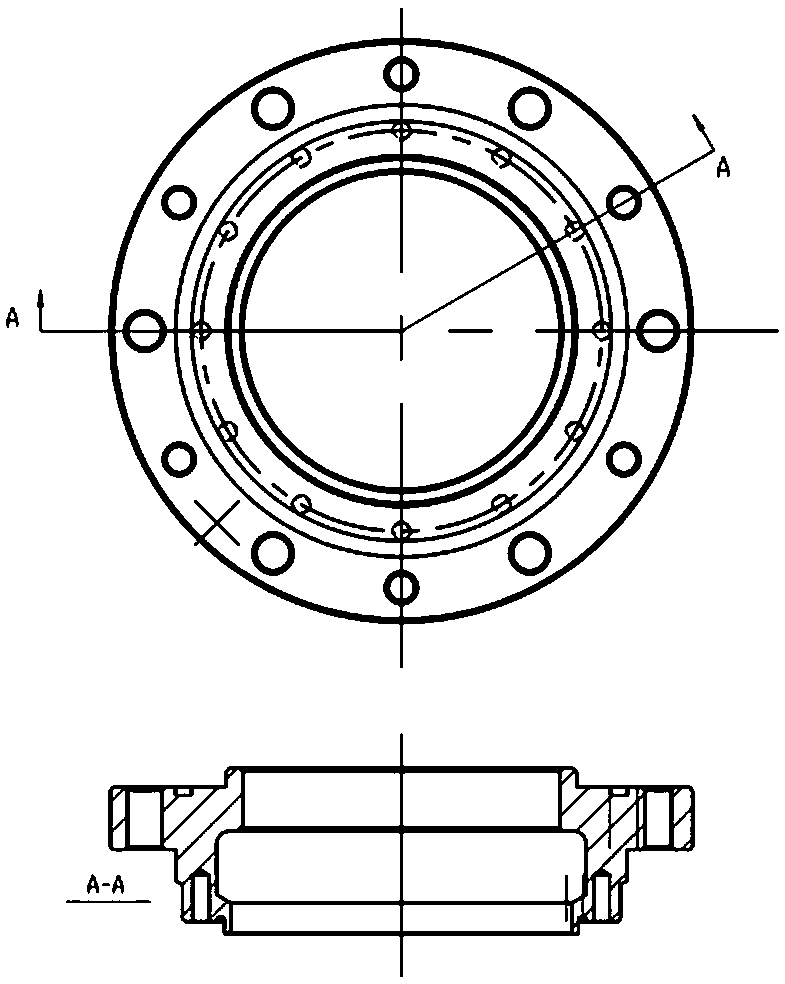

[0025] A harmonic reducer adopts the above technical scheme, in which the flexible wheel parameters are: R1 is 0.1mm, R2 is 0.5171mm, R3 is 0.3426mm, R4 is 0.1851mm, L1 is 0.3439mm, L2 is 0.4466mm, and h1 is 0.1583mm, h2 is 0.2417mm, h is 0.5164mm; the rigid wheel parameters are: R5 is 0.05mm, R6 is 0.5176mm, R7 is 0.6370mm, R8 is 0.1202mm, L3 is 0.3415mm, L4 is 0.4489mm, and h3 is 0.1233mm, h4 is 0.2571mm, H is 0.4940mm.

Embodiment 2

[0027] On the basis of the first embodiment, the parameters of the flexible wheel are changed to: R1 is 0.2mm, R2 is 0.0.6171mm, L1 is 0.5439mm, L2 is 0.6466mm, h1 is 0.2583mm, h2 is 0.3417mm; The parameters are changed to: R7 is 0.7370mm, R8 is 0.2202mm, L3 is 0.5415mm, L4 is 0.6489mm, h3 is 0.2233mm, and h4 is 0.3571mm.

Embodiment 3

[0029] On the basis of Example 1, the parameters of the flexible wheel are changed to: R1 is 0.15mm, R2 is 0.6071mm, L1 is 0.4398mm, L2 is 0.5315mm, h1 is 0.2057mm, h2 is 0.2678mm; the rigid wheel is changed to some parameters Change to: R7 is 0.6756mm, R8 is 0.1987mm, L3 is 0.4322mm, L4 is 0.5576mm, h3 is 0.1866mm, and h4 is 0.3056mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius size | aaaaa | aaaaa |

| Radius size | aaaaa | aaaaa |

| Radial height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com