Static-dynamic mixed oil film bearing

A mixed oil, dynamic and static pressure technology, applied in the direction of bearings, shafts and bearings, bearing components, etc., can solve the problems of contact wear between the main shaft and the bearing, low bearing capacity, and is only suitable for occasions with constant external loads, etc., to improve the rotation speed Accuracy, improvement of dynamic pressure effect, improvement of oil film rigidity and effect of homogenization error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment technical scheme of the present invention is further described as follows:

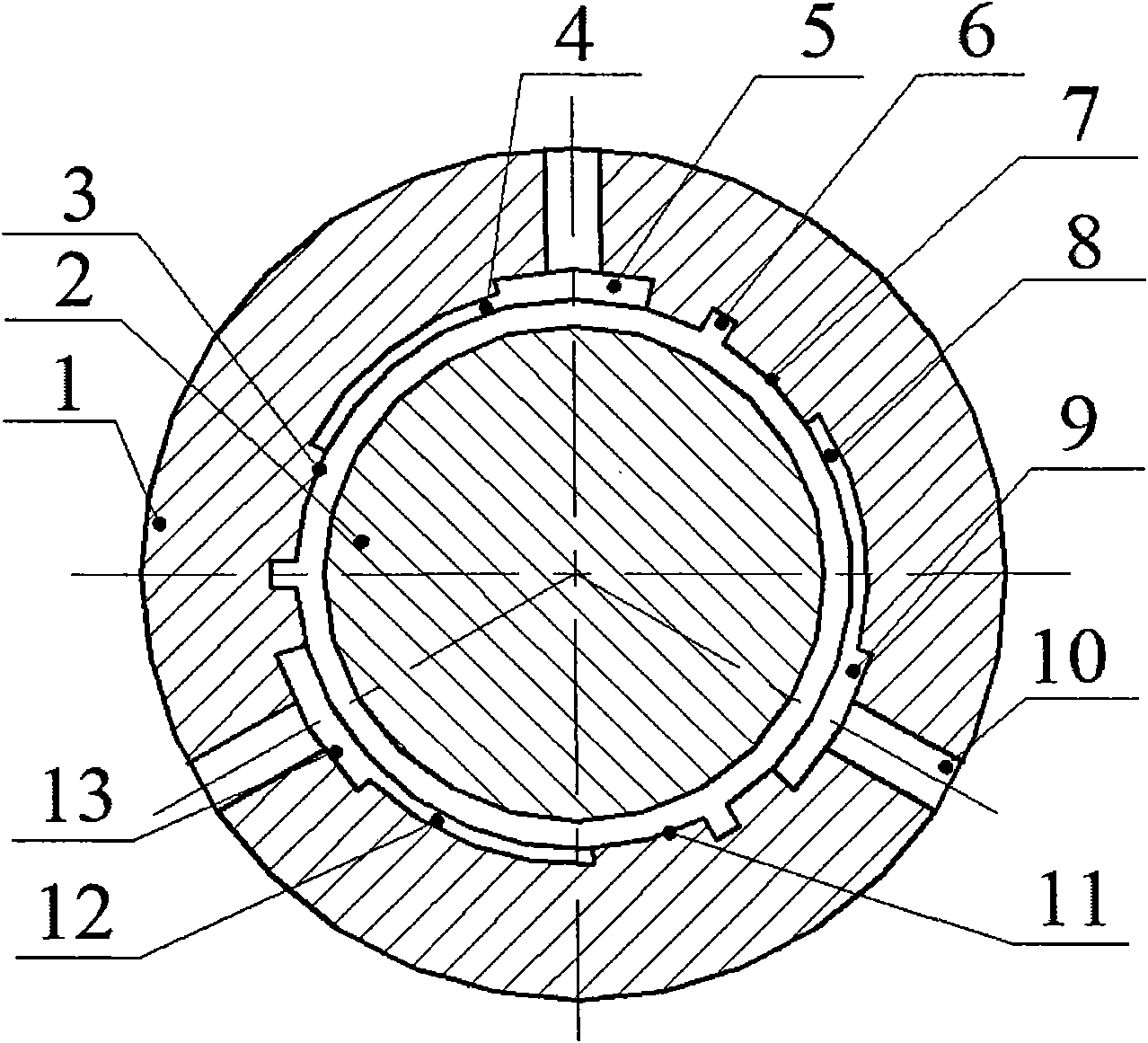

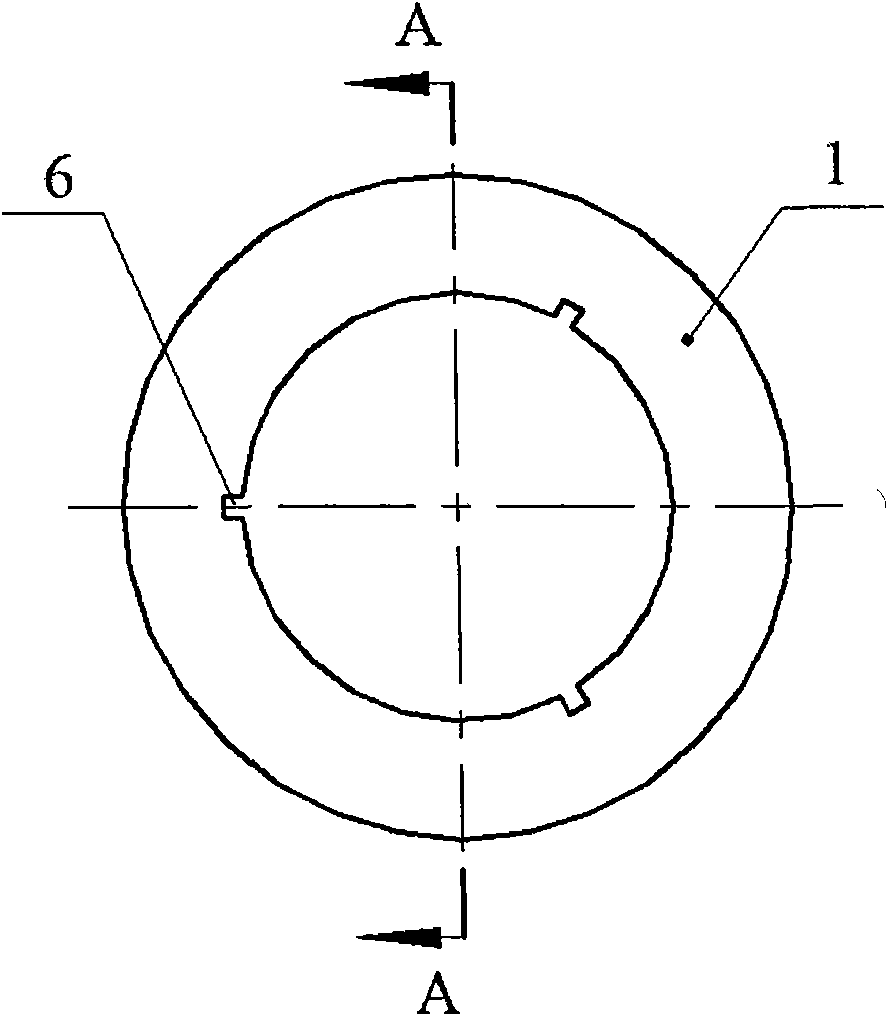

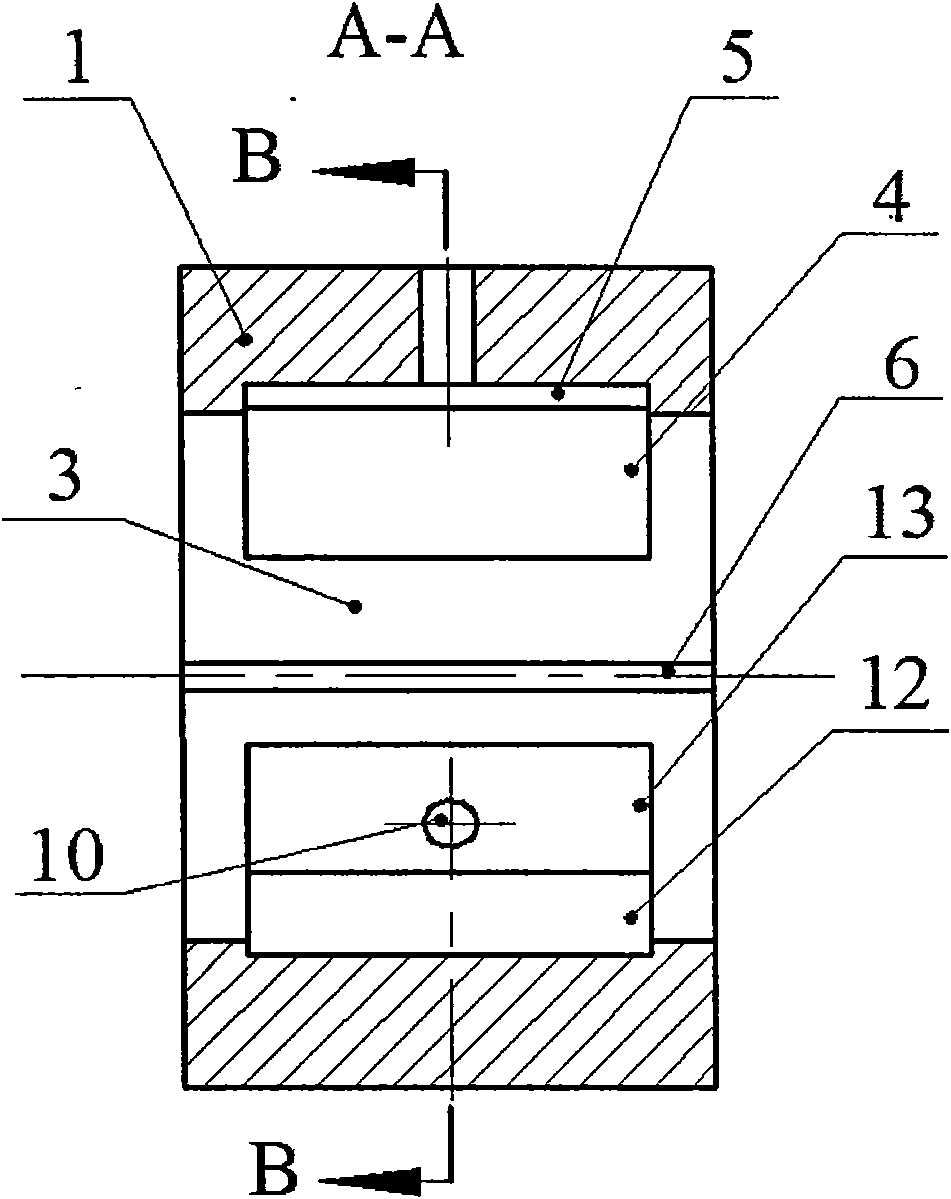

[0014] The structure of the present invention includes a dynamic and static pressure mixed oil film bearing 1 and a main shaft 2, and is characterized in that the inner hole surface of the dynamic and static pressure mixed oil film bearing 1 is provided with three static pressure chambers at 120° to each other, that is, the upper static pressure chamber 5, the front static pressure chamber chamber 9 and rear static pressure chamber 13, the pressure oil enters the above static pressure chambers through the oil inlet hole 10, and the pressure oil returns to the oil through three axial oil return grooves 6, and there are three There are two stepped chambers at 120° each other, namely the upper stepped chamber 4, the front stepped chamber 8 and the rear stepped chamber 12. The oil sealing surface between the above stepped chamber and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com