NiFe2O4 nano composite material and preparation method and application thereof

A technology of nanocomposite materials and composites, which is applied in the field of NiFe2O4 nanocomposite materials and its preparation, and can solve the problems of not being able to provide good charge-discharge cycle performance of electrodes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

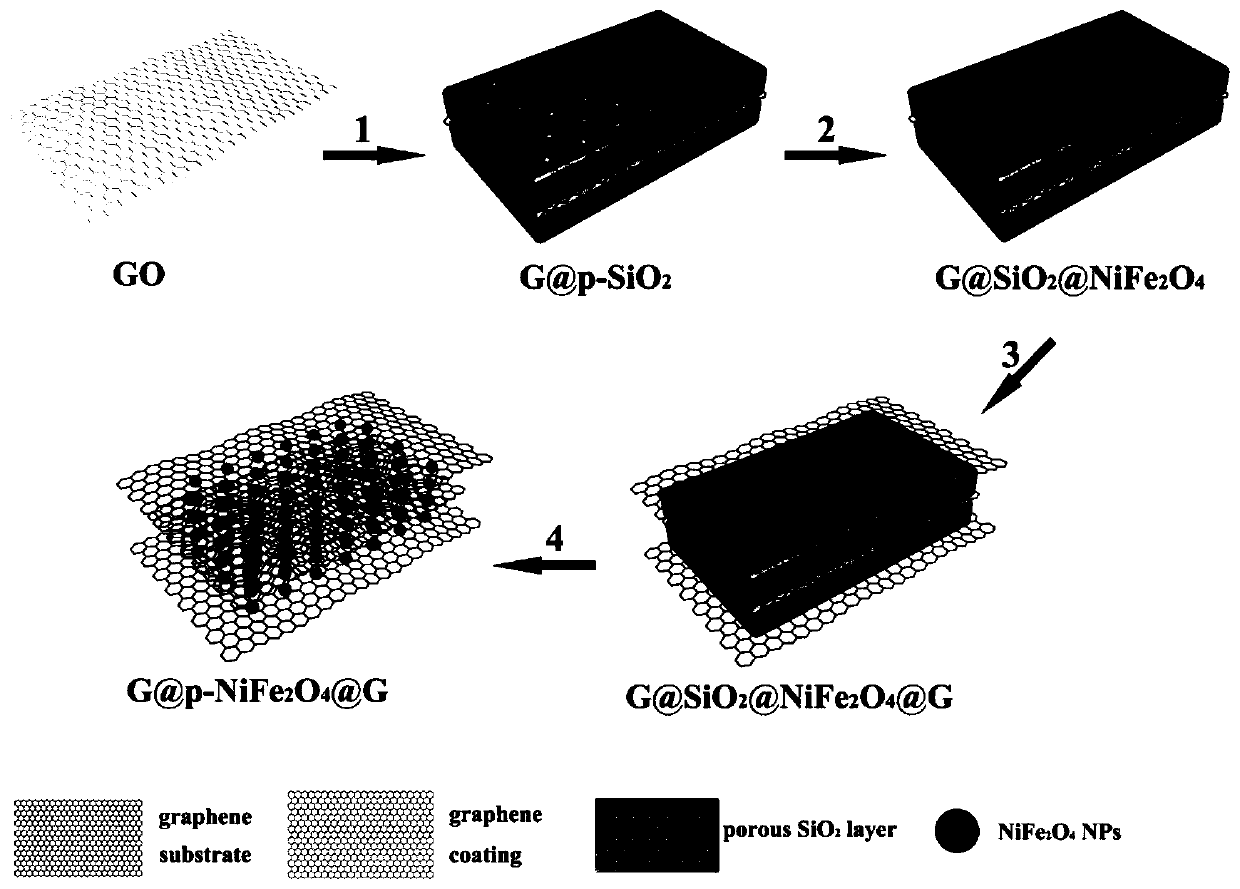

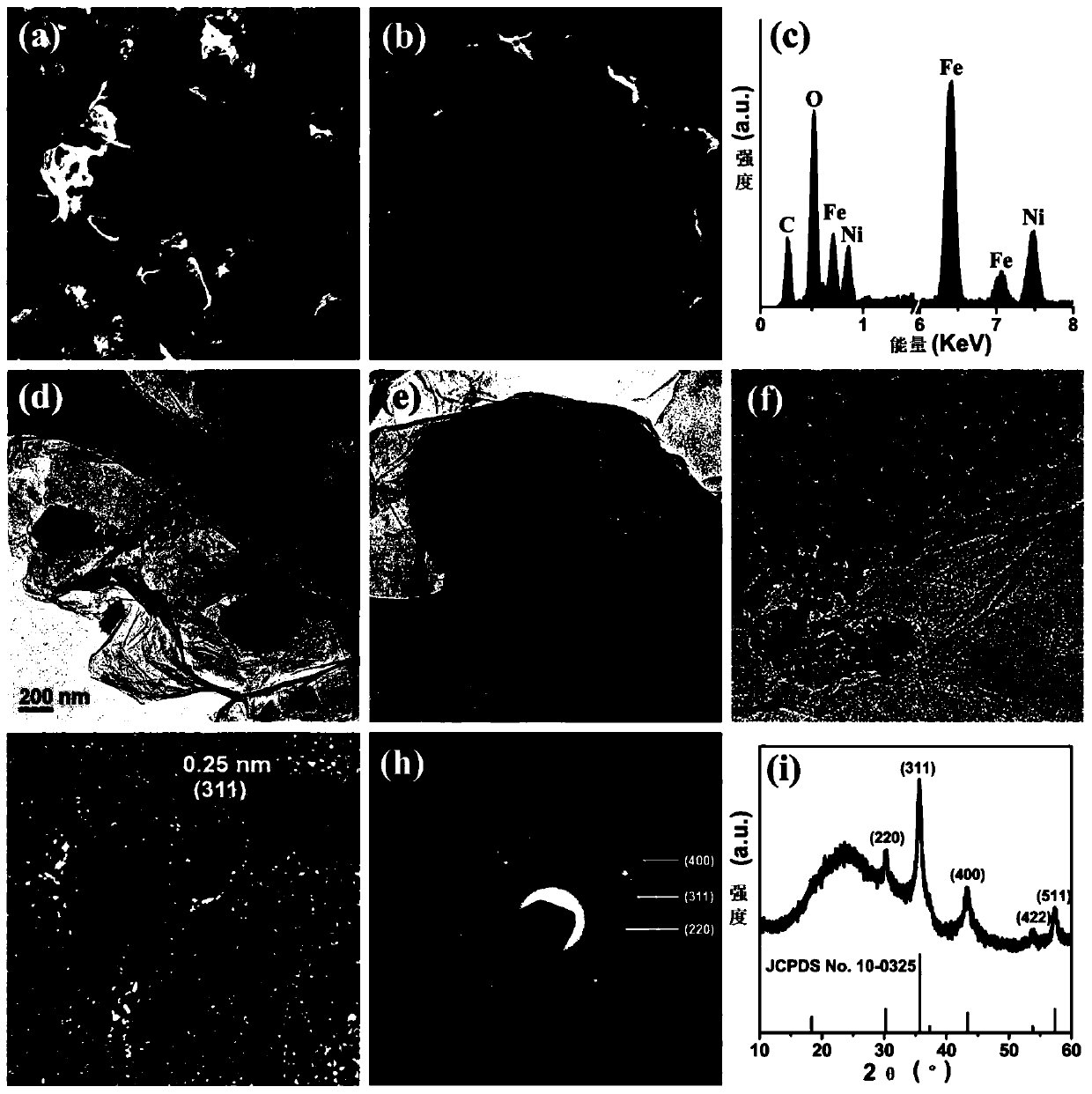

[0158] G@p-SiO 2 Synthesis of composite materials: 160mg cetyltrimethylammonium bromide (CTAB) was dissolved in 30mlH 2 O, 120ml ethanol and 1.5ml NH 3 .H 2 O mixture. Then, 40 mg GO was dispersed in the above solution by ultrasonication, and then 1 mL tetraethylorthosilicate (TEOS) was slowly added and kept stirring for 12 h. with H 2 After O washing and drying at 80 °C, the product was further annealed at 800 °C for 3 h under Ar atmosphere to obtain G@p-SiO 2 Composite, wherein, the mass content of graphene is 6.3wt%.

[0159] 100mg G@p-SiO 2 (graphene composite coated with porous silica on the surface) was added to the 3 ) 3 9H 2 O and 0.25mmol Ni(NO 3 ) 2 ·6H 2 O in 10 mL of ethanol. After sonication for 10 min, the above solution was stirred at 45 °C to evaporate ethanol. The product was annealed in Ar at 350 °C for 3 h. Then the obtained G@SiO 2 @NiFe 2 o 4 Complex in 100ml H 2 Sonicate with 1 mL of polydiallyldimethylammonium chloride (PDDA, 20 wt%, ...

Embodiment 2

[0164] The difference between this embodiment and embodiment 1 is:

[0165] G@p-SiO 2 Synthesis of composite materials: 160mg cetyltrimethylammonium bromide (CTAB) was dissolved in 30mlH 2 O, 120ml ethanol and 1.5ml NH 3 .H 2 O mixture. Then, 18.4 mg GO was dispersed in the above solution by ultrasonication, and then 1 mL tetraethyl orthosilicate (TEOS) was slowly added and kept stirring for 12 h. with H 2 After O washing and drying at 80 °C, the product was further annealed at 800 °C for 3 h under Ar atmosphere to obtain G@p-SiO 2 Composite, wherein, the mass content of graphene is 3wt%.

[0166] 100mg G@p-SiO 2 (graphene composite coated with porous silica on the surface) was added to the 3 ) 3 9H 2 O and 0.15mmol Ni(NO 3 ) 2 ·6H 2 O in 10 mL of ethanol. After sonication for 10 min, the above solution was stirred at 45 °C to evaporate ethanol. The product was heated at 300°C under N 2 Medium annealing for 12 hours. Then the obtained G@SiO 2 @NiFe 2 o 4 Co...

Embodiment 3

[0169] The difference between this embodiment and embodiment 1 is:

[0170] G@p-SiO 2 Synthesis of composite materials: 160mg cetyltrimethylammonium bromide (CTAB) was dissolved in 30mlH 2 O, 120ml ethanol and 1.5ml NH 3 .H 2 O mixture. Then, 81.3 mg GO was dispersed in the above solution by ultrasonication, and then 1 mL tetraethylorthosilicate (TEOS) was slowly added and kept stirring for 12 h. with H 2 After O washing and drying at 80 °C, the product was further annealed at 800 °C for 12 h under Ar atmosphere to obtain G@p-SiO 2 Composite, wherein, the mass content of graphene is 12wt%.

[0171] 100mg G@p-SiO 2 (graphene composite coated with porous silica on the surface) was added to the 3 ) 3 9H 2 O and 0.2mmol Ni(NO 3 ) 2 ·6H 2 O in 10 mL of ethanol. After sonication for 10 min, the above solution was stirred at room temperature to evaporate ethanol. The product was heated at 500°C under N 2 Anneal for 1 hour. Then the obtained G@SiO 2 @NiFe 2 o 4 Com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com