Forming method of semiconductor structure

A semiconductor and bonding layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems that the semiconductor structure formation method needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] According to the background technology, the performance of the existing semiconductor structure still needs to be improved.

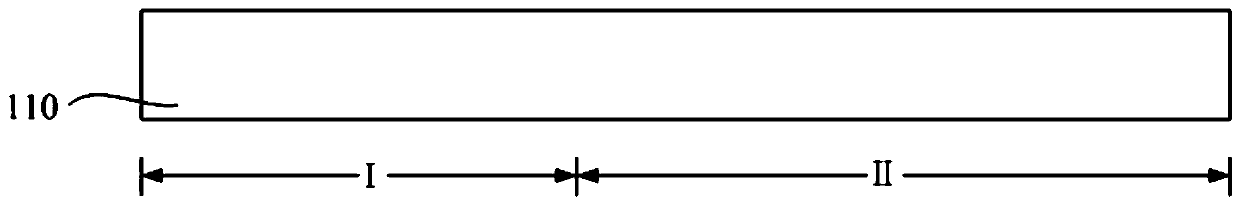

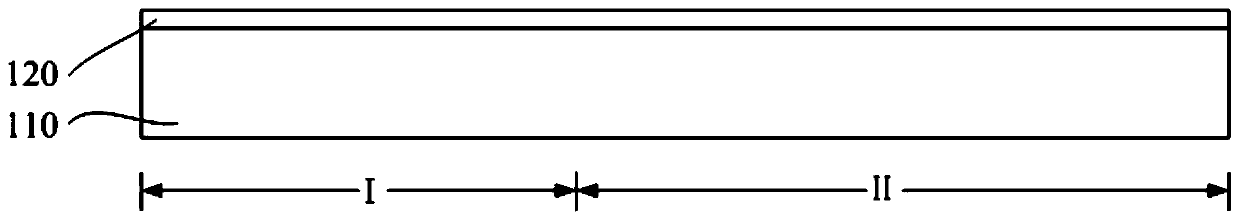

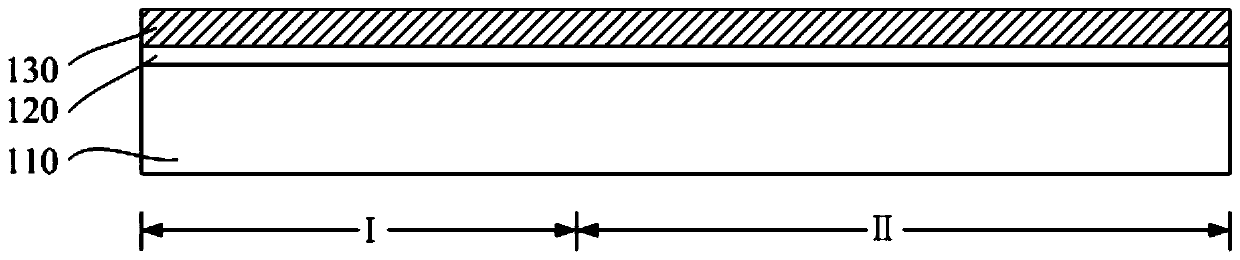

[0020] The analysis is now combined with a method for forming a semiconductor structure. The process steps for forming a semiconductor structure mainly include: providing a substrate, the substrate including a first region and a second region; forming a dielectric layer on the surface of the substrate, the first region The dielectric layer has a first through hole, the dielectric layer in the second region has a second through hole, and the opening of the first through hole is the same as the opening of the second through hole; In the process step, a first oxide layer is formed on the sidewall and bottom of the first through hole, and a second oxide layer is formed on the sidewall and bottom of the second through hole; in the same process step, etching is removed The first oxide layer located at the bottom of the first through hole, the second oxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com