Transformer vacuum oil injection system

A transformer and vacuum technology, applied in the field of transformers, can solve problems such as excessive oil pressure, fast oil filling speed, overflow of transformer oil to the leakage pipeline, etc., and achieve the effect of tight logic and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific examples are given below to further describe the technical solution of the present invention in a clear, complete and detailed manner. This embodiment is the best embodiment on the premise of the technical solution of the present invention, but the protection scope of the present invention is not limited to the following embodiments.

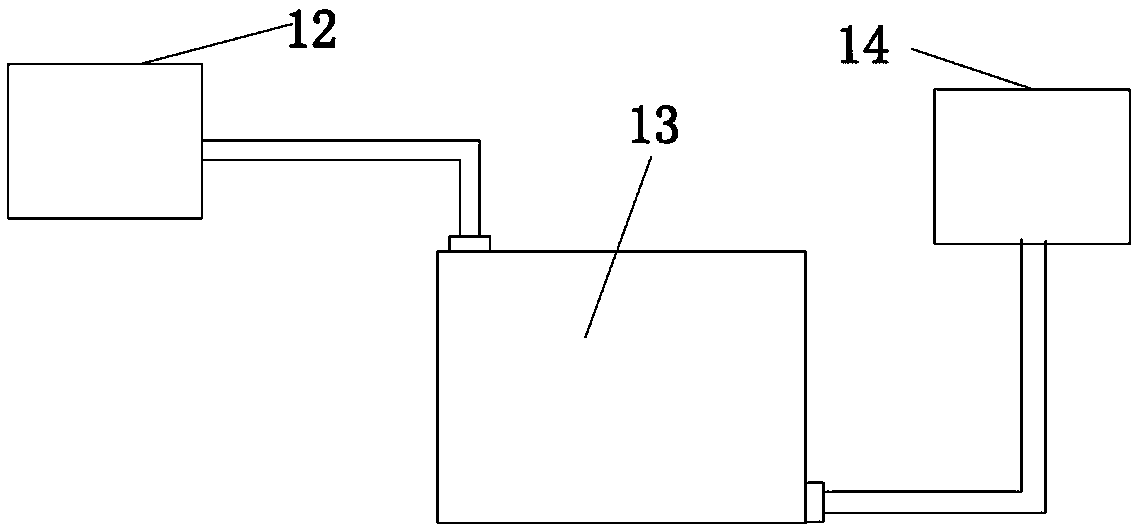

[0027] A transformer vacuum oiling system, comprising a vacuum part 12, a transformer 13 and an oil injection part 14 connected in sequence, the vacuum part 12 is connected to the upper end of the transformer 13, and the oil injection part 14 is connected to the lower end of the transformer 13;

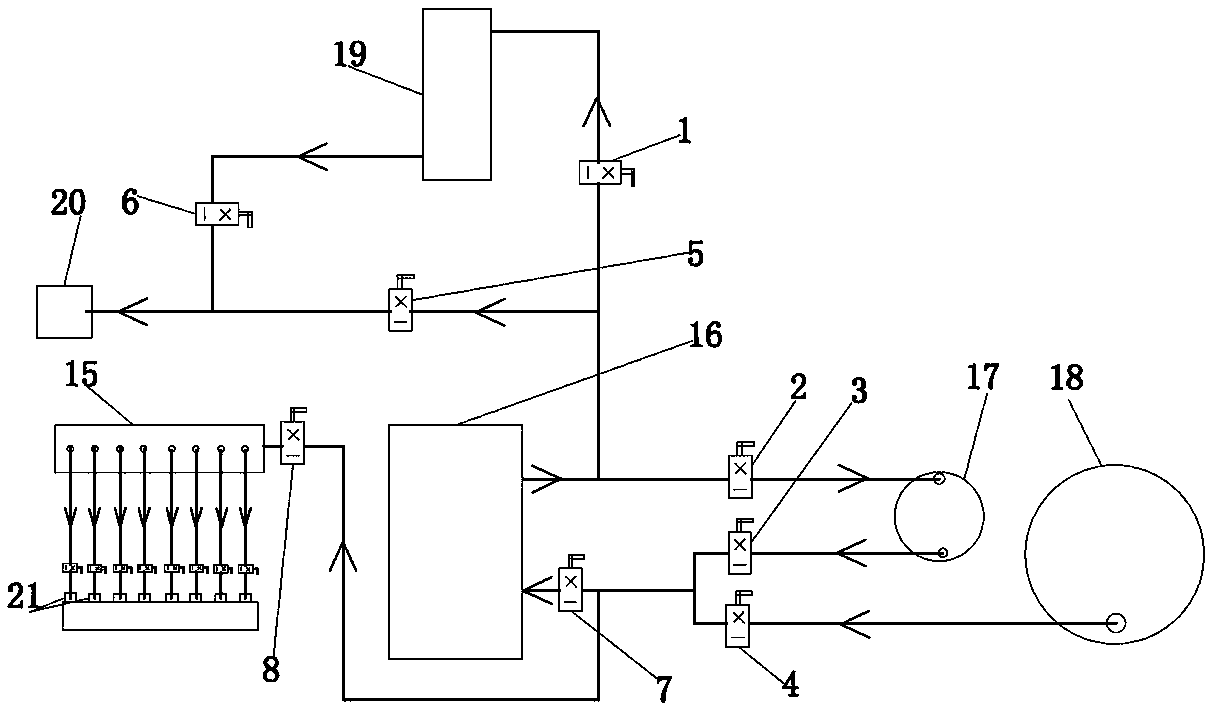

[0028] The oil injection part 14 includes a vacuum oil injection pipe 15, an oil filter unit 16, a first oil tank 17, a second oil tank 18, an oil supplement hanging tank 19, a first oil circuit, a second oil circuit, a third oil circuit, a Four oil circuits and the fifth oil circuit; the first oil tank 17 and the second oil tank 18 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com