Sludge mixed combustion system used for dry type slag extractor

A dry type slag discharger and sludge technology, which is applied in the field of sludge blending and burning system, can solve the problems such as the inability to control the air intake of the dry type slag discharger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

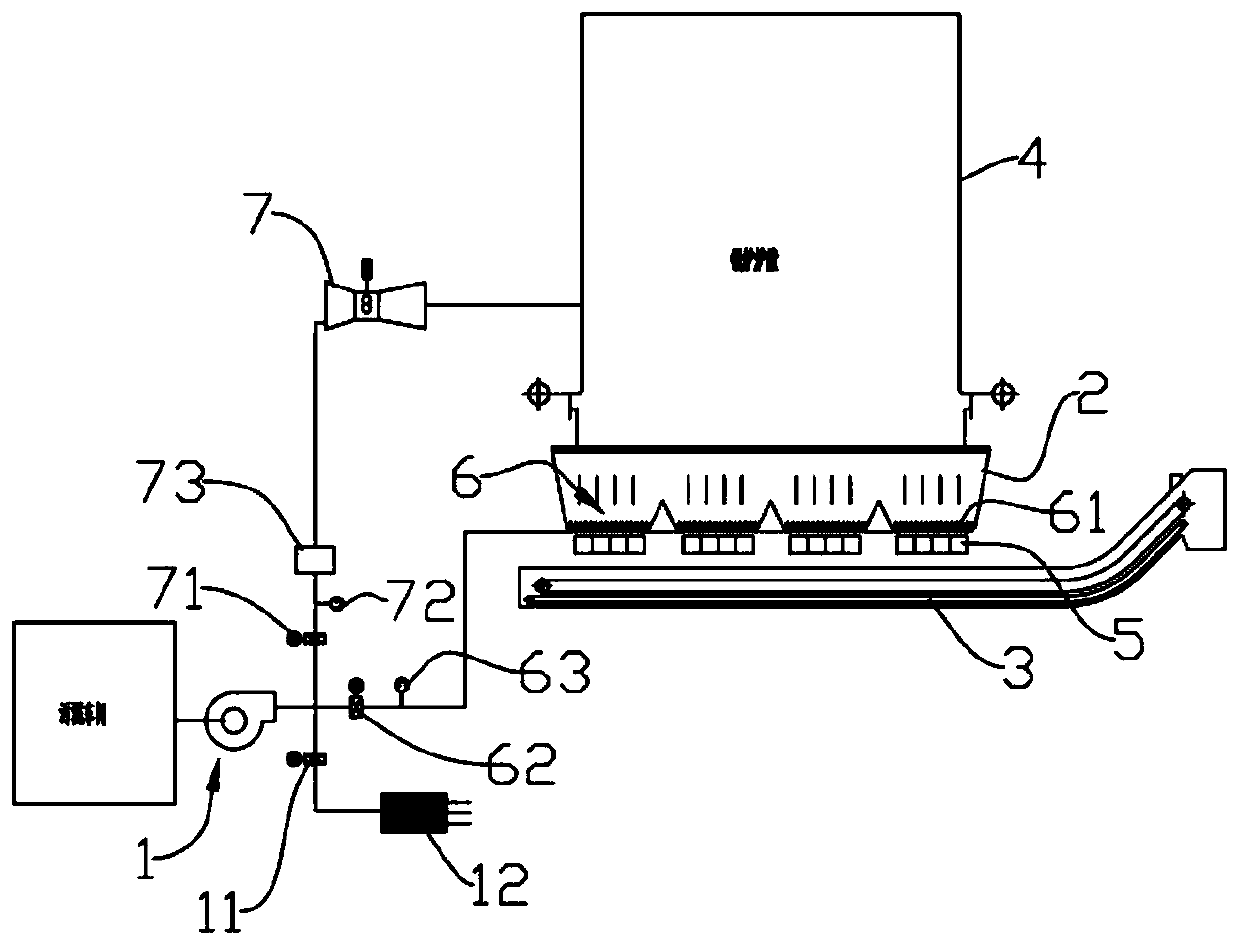

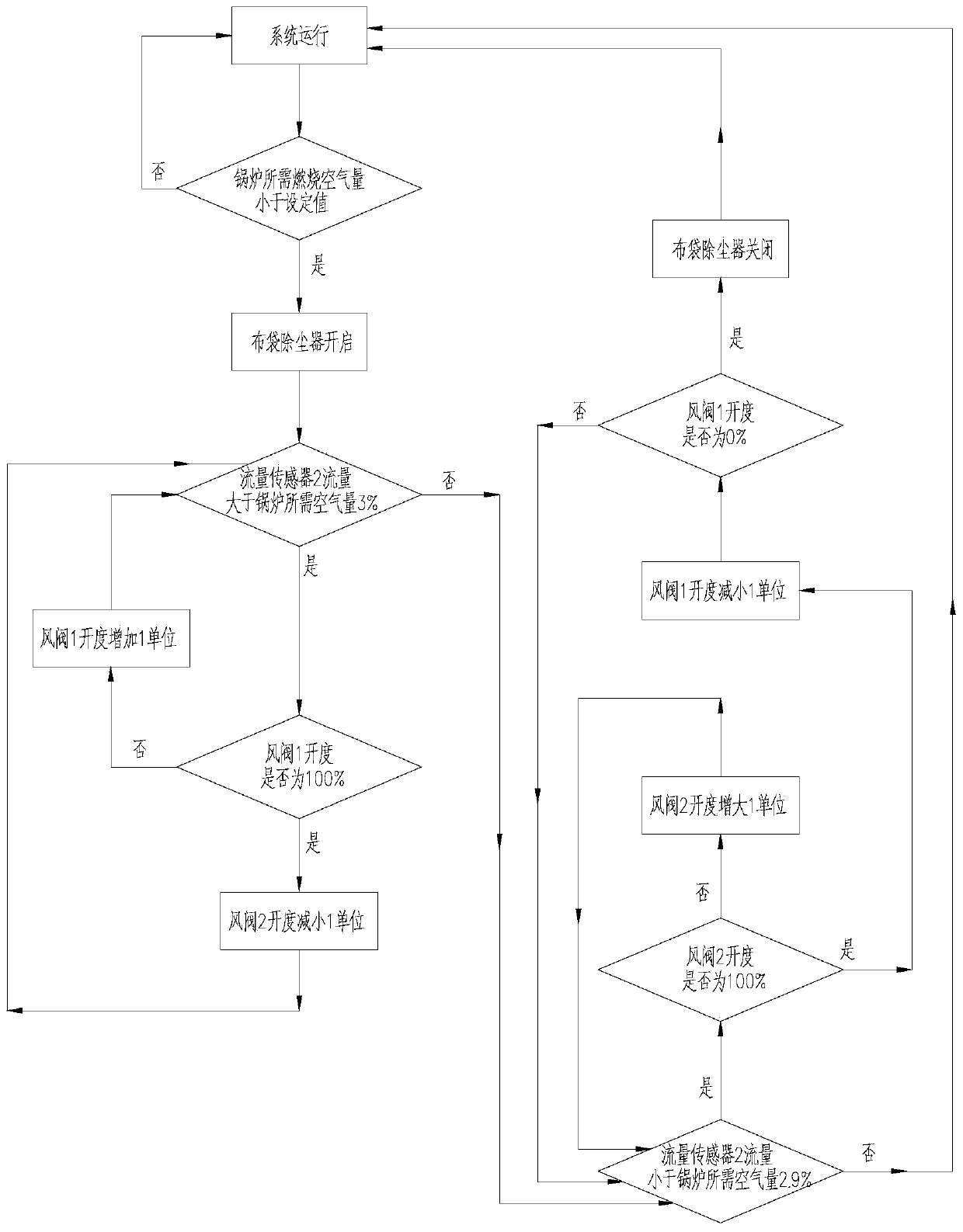

[0022] combine figure 1 and figure 2 As shown, the sludge blending system for dry slagging machine of the present invention is schematically shown, including exhaust gas source 1, transition slag hopper 2 and dry slagging machine 3, wherein dry slagging machine 3 Existing equipment is adopted, but the original air inlet on the fuselage of the dry slag discharger 3 should be blocked by devices such as baffles to prevent air from entering the dry slag discharger 3 from the above air inlet. Of course, the baffle It can be rotatably connected to the dry slag discharger 3, and the baffle can be driven by manual or existing mechanical equipment such as cylinders to block or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com