Floating rubber dam

A rubber dam and floating technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as construction difficulties, maintenance and replacement difficulties, affecting landscape and navigation, etc., to reduce damage or impact, and facilitate replacement and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

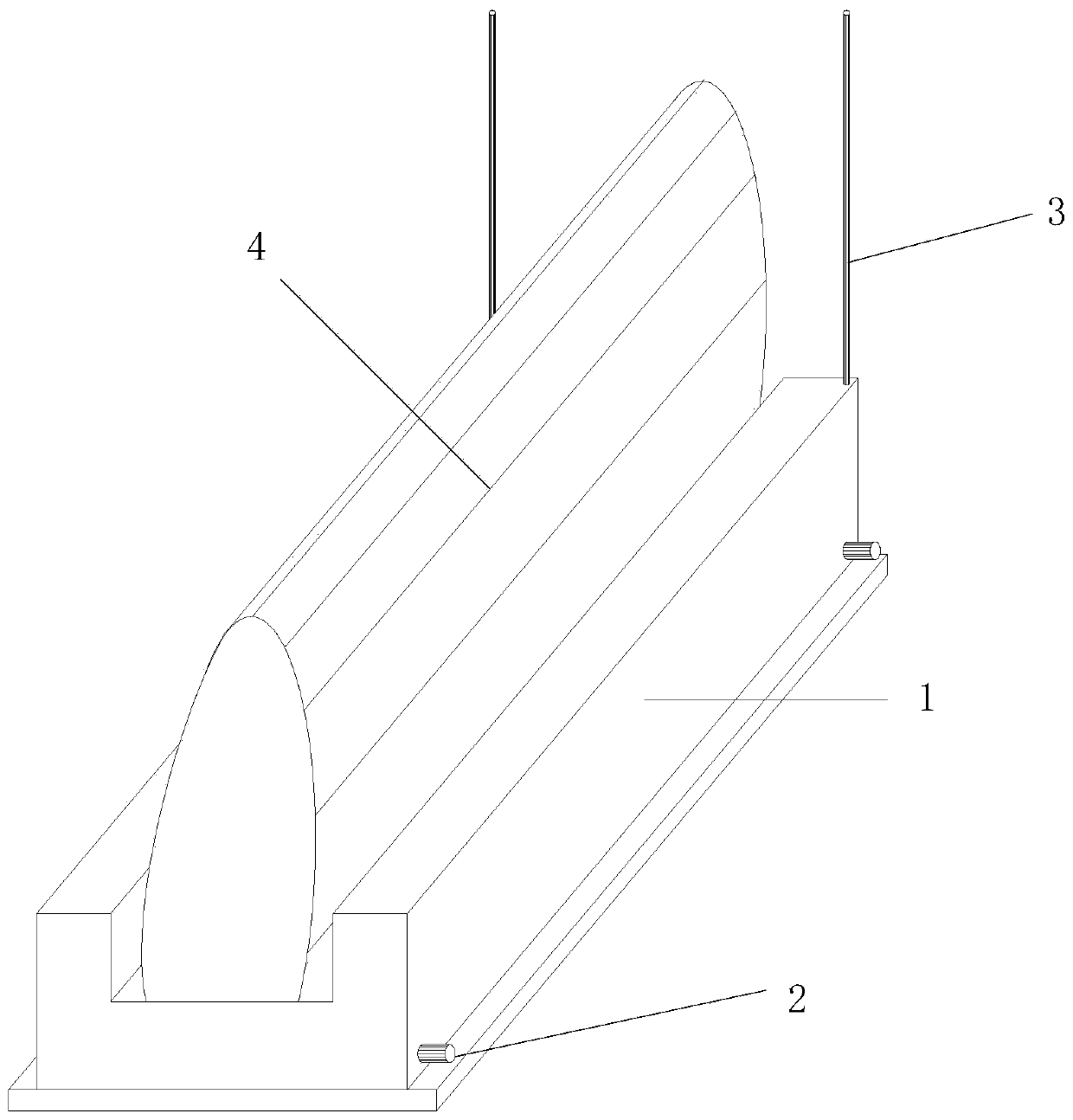

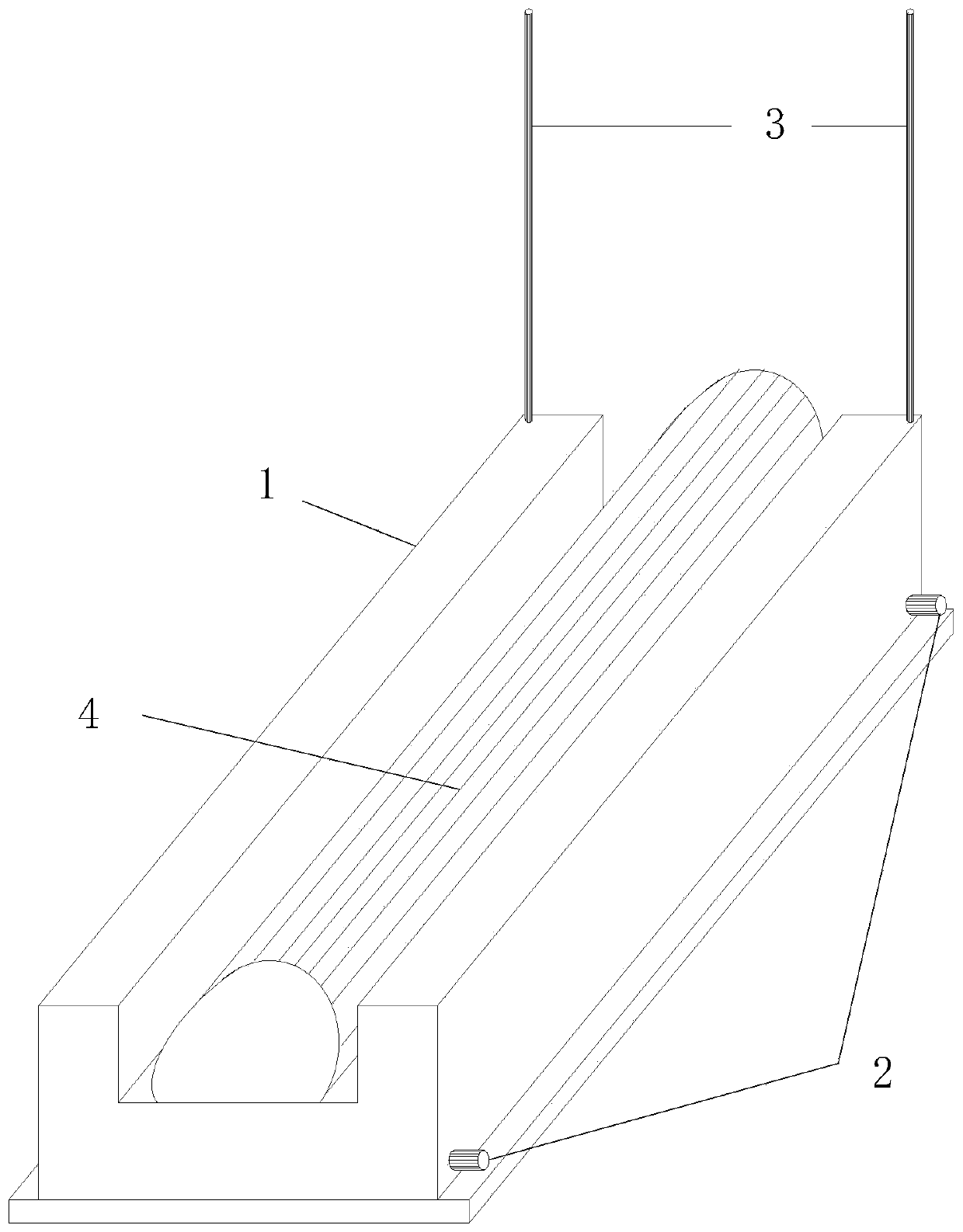

[0044] Such as Figure 1 to Figure 2 As shown, the invention provides a floating rubber dam, comprising:

[0045] A buoyant tank 1, the buoyant tank 1 is used to be placed on the bottom of the water, the side wall of the buoyant tank 1 is provided with a filling and discharging pipe 2, and the top of the buoyant tank 1 is provided with a vent pipe 3, and the vent pipe 3 protrudes from the water surface;

[0046] The dam bag 4, the dam bag 4 is connected to the top of the buoyancy tank 1.

[0047] In this embodiment, the cross section of the buoyancy tank 1 is concave, and the dam bag 4 is connected in the middle of the concave.

[0048] The bottom of the dam bag 4 is provided with connecting plates extending to both sides, and the middle of the buoyancy tank 1 is provided with a pressing plate, and the connecting plate is located below the pressing plate. The height of the top surface of the dam bag 4 when not filling with water does not exceed the height of the top surface ...

Embodiment 2

[0059] The difference between this embodiment and embodiment 1 is that

[0060] In this embodiment, the filling and draining pipe 2 is used to communicate with the filling and draining system, the dam bag 4 is connected to the filling and exhausting system, and the bottom of the dam bag 4 is provided with a pressure regulating pipe protruding from the water surface. When the dam bag 4 is inflatable, the dam bag 4 is not connected to the buoyancy tank 1, and the dam bag 4 is connected to the inflation and exhaust system alone to realize inflation and exhaust, and the dam bag 4 is provided with a pressure regulating pipe to avoid excessive inflation pressure And burst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com