Coiling device for sliver can conversion, textile machinery with soiling device and combination

A technology of textile machinery and cans, which is applied in the field of textile machinery and equipment, can solve the problems of high cost and high cost, achieve high production efficiency, save machine transformation costs, and simplify design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

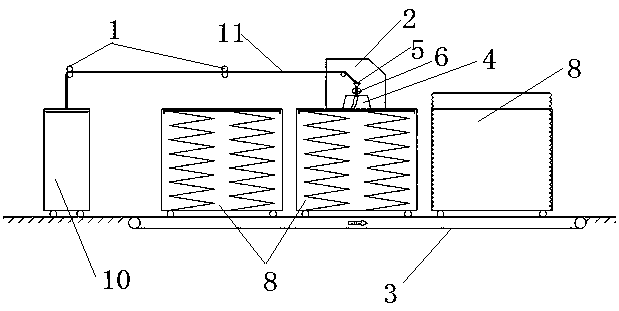

[0039] This embodiment describes a coiling device for can conversion, which comprises at least one rectangular can 8 for storing fiber sliver 11, for driving said coiling disc 4 relative to said rectangular can. The driving mechanism of the relative movement of the bar can 8, the feed of the coiled disc 4 comes from at least one circular bar can 10 for storing fiber strips 11, and the output of the coiled disc 4 is stored in at least one for storing The rectangular can 8 of the fiber sliver 11, the driving mechanism is used for when the coiling device is in working condition, the coiling disc 4 is driven by the driving mechanism to form an axial direction above the rectangular can 8. movement, and at the same time make a linear reciprocating motion in the horizontal plane above the rectangular can 8, for converting the fiber strips 11 in the circular can 10 into the rectangular can 8.

[0040] Such as figure 1 As shown, the coiling device can include a guide frame 1, a fixed ...

Embodiment 2

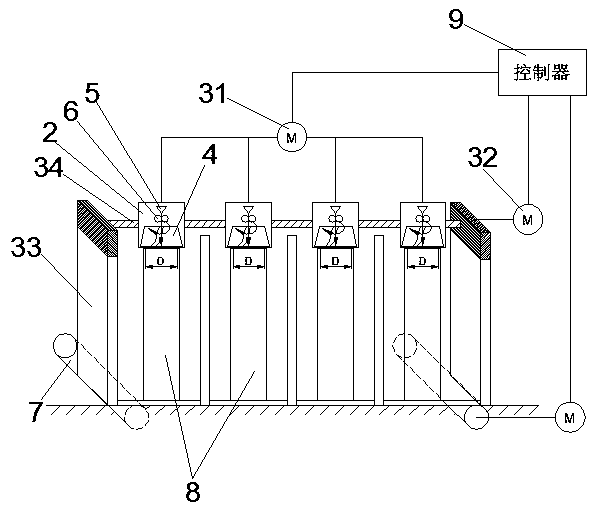

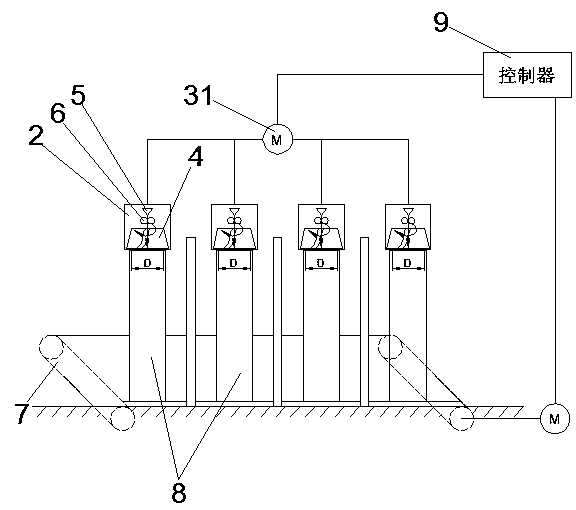

[0050] This embodiment describes a coiling device for can conversion, which comprises at least one rectangular can 8 for storing fiber sliver 11, for driving said coiling disc 4 relative to said rectangular can. The driving mechanism of the relative movement of the bar can 8, the feed of the coiled disc 4 comes from at least one circular bar can 10 for storing fiber strips 11, and the output of the coiled disc 4 is stored in at least one for storing The rectangular bar can 8 of the fiber sliver 11, the driving mechanism is used for when the sliver coiling device is in working condition, the coiling disc 4 is driven by the driving mechanism to only act as a shaft on the top of the rectangular bar can 8 and at the same time, the driving mechanism drives and controls the rectangular can 8 to do linear reciprocating motion in the horizontal plane below the coiling disc 4, for converting the fiber strips 11 in the circular cans 10 into rectangular strips. Inside the cylinder 8.

...

Embodiment 3

[0059] The present embodiment provides a textile machine comprising a coiling device for can conversion as described above. That is, the coiling device for can conversion of the present invention is used as an auxiliary machine of a textile machine, and the structure of the coiling device can be as described in any of the above-mentioned embodiments and will not be repeated here. Before the fiber sliver enters the textile machine, it is transferred from a circular can to a rectangular can, so that the feeding cylinder of the textile machine is a rectangular can with high space utilization and larger capacity, and there is no need to carry out the traditional fiber sliver 11 output textile machine. Any modification, save the cost of machine modification and increase productivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com