Drilling fluid treatment agent and preparation method

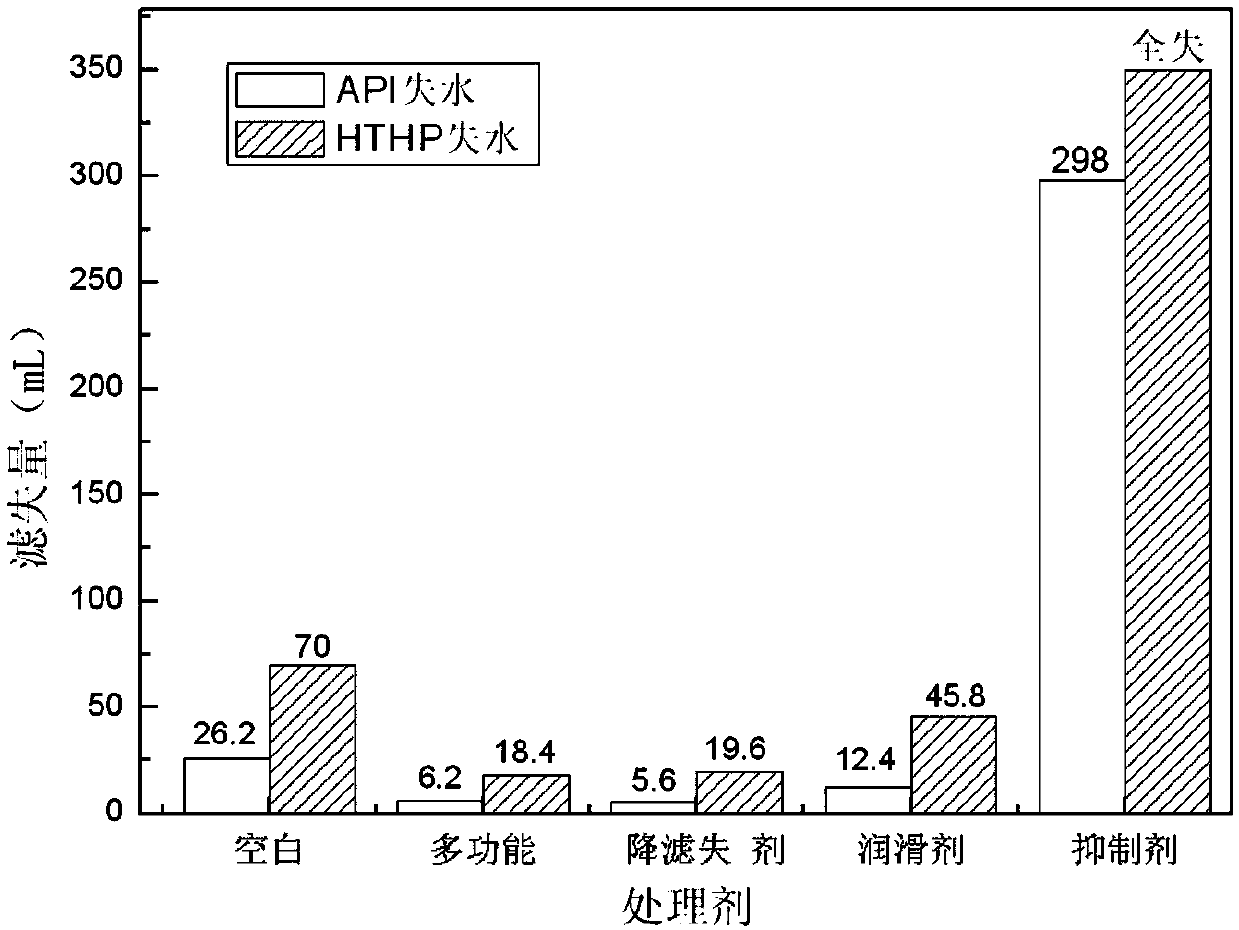

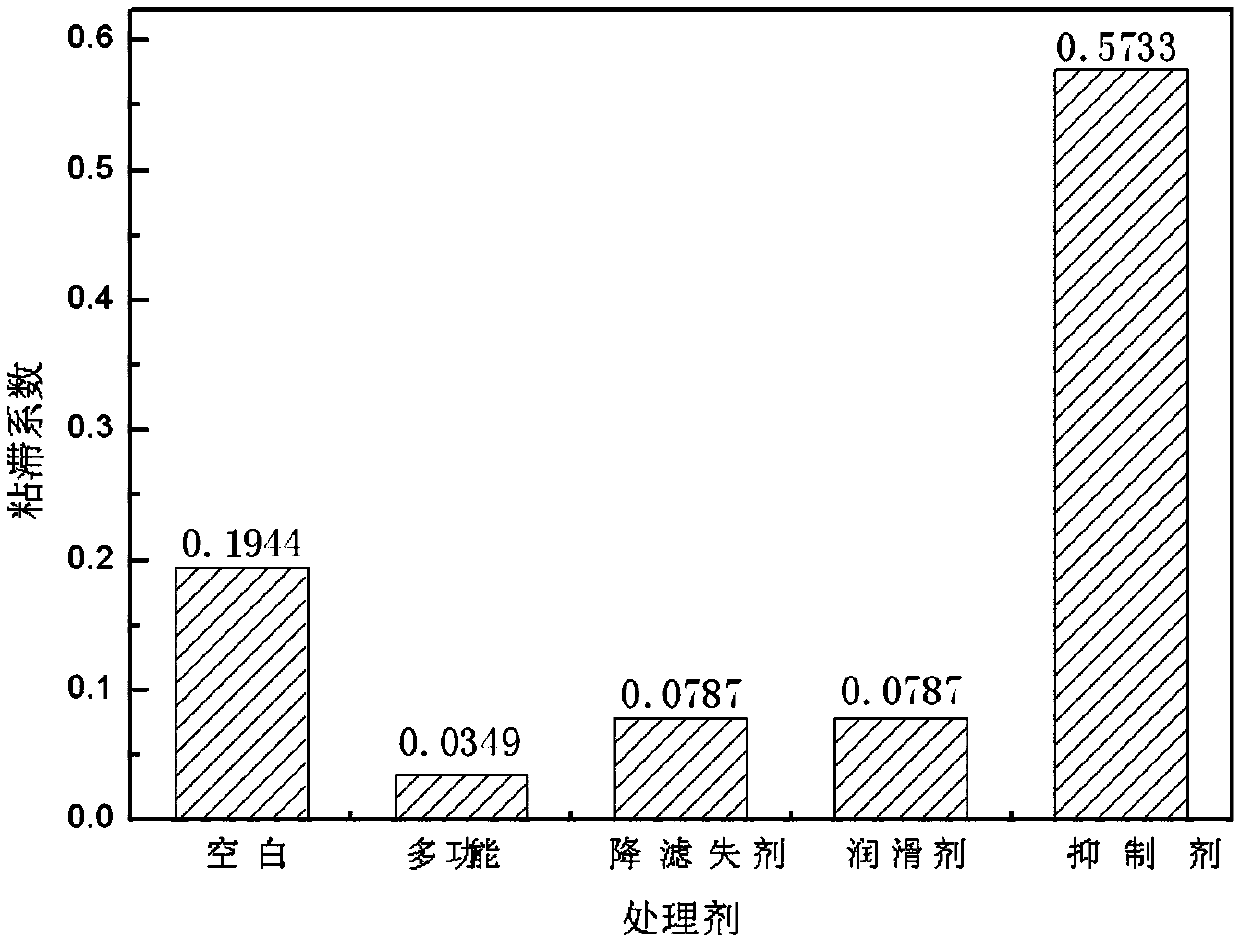

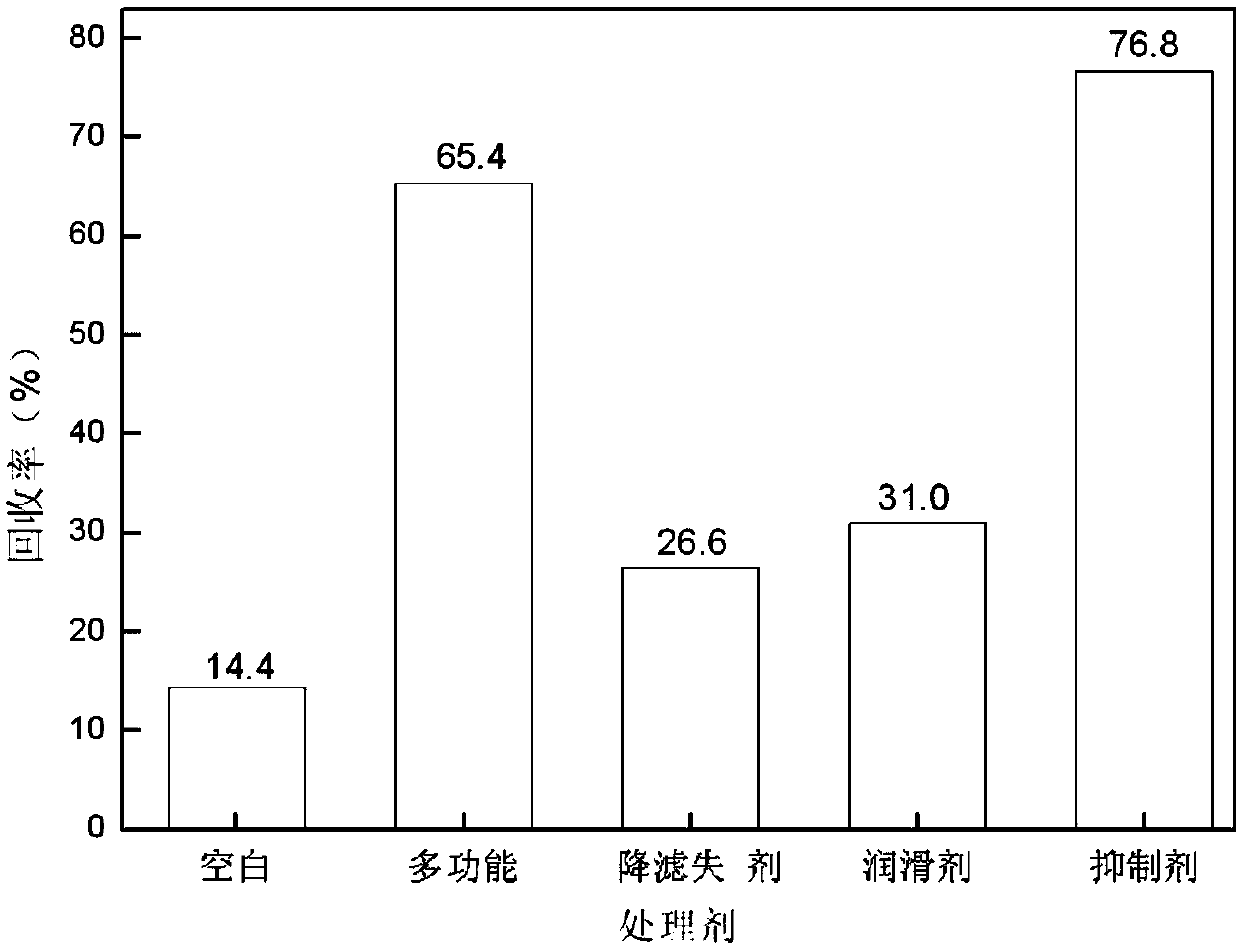

A drilling fluid treatment agent and solution technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of many kinds of treatment agents, complex systems, difficult maintenance of drilling fluid, etc., to achieve good filtration reduction, Good compatibility and low dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The multifunctional drilling fluid treatment agent of the present embodiment is prepared by the following method:

[0050] First add monomer 1 2-acrylamido-2-methylpropanesulfonic acid and monomer 2 acrylic acid to water, adjust the pH value of the solution and then add monomer 3N, N-methylenebisacrylamide and monomer 4 diene Propyl dimethyl ammonium chloride, adding initiator 1, hydrogen peroxide and initiator 2, sodium bisulfite, reacted at a constant temperature for 4 hours, then sheared, dried, and pulverized to prepare a multifunctional drilling fluid treatment agent product. The specific steps are: add 7 parts of monomer 1 2-acrylamido-2-methylpropanesulfonic acid and 3 parts of monomer 2 acrylic acid to 100 parts of water at room temperature, stir until completely dissolved and then use pH regulator sodium hydroxide 2.5 Adjust the pH of the solution to 9.0, add 4 parts of monomer 3N,N-methylenebisacrylamide and 3 parts of monomer 4 diallyldimethylammonium chlorid...

Embodiment 2

[0053] The multifunctional drilling fluid treatment agent of the present embodiment is prepared by the following method:

[0054] First add monomer 1 sodium methacrylate and monomer 2 tert-butyl acrylate to the water, adjust the pH value of the solution and then add monomer 3N-methylolacrylamide and monomer 4 trimethylglycidyl chloride ammonium, add initiator 1 ammonium persulfate and initiator 2 tetraethyleneimine to react at constant temperature for 4 hours, then shear, dry and pulverize to prepare a multifunctional drilling fluid treatment agent product. The specific steps are: add 21 parts of monomer 1 sodium methacrylate sulfonate and 10.5 parts of monomer 2 tert-butyl acrylate to 100 parts of water at room temperature, stir until completely dissolved, and adjust the pH of the solution with 4 parts of pH regulator calcium hydroxide. Adjust to 8.0, add 32 parts of monomer 3N-methylolacrylamide and 5.5 parts of monomer 4 trimethylglycidyl ammonium chloride to the solution, ...

Embodiment 3

[0057] The multifunctional drilling fluid treatment agent of the present embodiment is prepared by the following method:

[0058] First add monomer 1 acrylamidophenylethanesulfonic acid and monomer 2 methacrylate to the water, adjust the pH value of the solution and add monomer 3N-butoxymethacrylamide and monomer 4 trimethylallyl base ammonium chloride, add initiator 1 sodium perchlorate and initiator 2 sodium thiosulfate and react at constant temperature for 4 hours, then shear, dry and pulverize to prepare a multifunctional drilling fluid treatment agent product. The specific steps are: add 14 parts of monomer 1 acrylamidophenylethanesulfonic acid and 6 parts of monomer 2 methacrylate to 100 parts of water at room temperature, stir until completely dissolved, and then use 2.5 parts of pH regulator magnesium hydroxide to dissolve Adjust the pH of the solution to 7.0, add 21 parts of monomer 3N-butoxymethacrylamide and 4.2 parts of monomer 4 trimethylallyl ammonium chloride to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| filtration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com