Method for preparing ordinary Portland cement from vanadium-titanium slag partially instead of mineral slag

A technology of ordinary Portland cement and Portland cement, which is applied in cement production, etc., can solve problems such as insufficient utilization of vanadium-titanium slag, chloride ions exceeding the national standard, and 28-day strength reduction of cement. It is conducive to the rational use of resources, the effect of relieving environmental pressure and reducing environmental burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

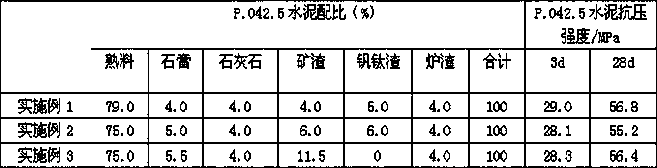

Embodiment 1

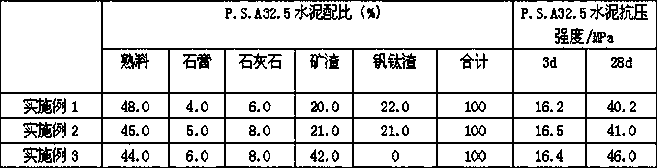

[0025] The invention provides a vanadium-titanium slag instead of slag to produce ordinary Portland cement, including P.S.A32.5 and P.O42.5 Portland cement. The main materials used in the Portland cement include: clinker, Gypsum, limestone, coal-fired slag, slag and vanadium-titanium slag;

[0026] The preparation method of P.S.A32.5 cement, the specific operation steps are:

[0027] Step 1: Purchase clinker, gypsum, limestone, slag and vanadium-titanium slag;

[0028] Step 2: Take the above raw materials in proportion, mix them into the mill according to 48% of clinker, 4% of gypsum, 6% of limestone, 20% of slag and 22% of vanadium-titanium slag, and the total amount of slag and vanadium-titanium slag accounts for the total amount of the mixture 42% of that, the gypsum is set as low chlorine gypsum;

[0029] Step 3: Add a liquid grinding aid mainly based on triethanolamine in the grinding process, the mixing ratio is 0.035-0.045%, and the cement ratio is controlled at 400-4...

Embodiment 2

[0038] The invention provides a vanadium-titanium slag instead of slag to produce ordinary Portland cement, including P.S.A32.5 and P.O42.5 Portland cement. The main materials used in the Portland cement include: clinker, Gypsum, limestone, coal-fired slag, slag and vanadium-titanium slag;

[0039] The preparation method of P.S.A32.5 cement, the specific operation steps are:

[0040] Step 1: Purchase clinker, gypsum, limestone, slag and vanadium-titanium slag;

[0041] Step 2: Take the above raw materials in proportion, mix them into the mill according to 45% of clinker, 5% of gypsum, 8% of limestone, 21% of slag and 21% of vanadium-titanium slag, and the total amount of slag and vanadium-titanium slag accounts for the total amount of the mixture 42% of that, the gypsum is set as low chlorine gypsum;

[0042] Step 3: Add liquid grinding aid mainly composed of triethanolamine in the grinding process, the mixing ratio is 0.035-0.045%, and the cement ratio is controlled at 400-...

Embodiment 3

[0051] The invention provides a vanadium-titanium slag instead of slag to produce ordinary Portland cement, including P.S.A32.5 and P.O42.5 Portland cement. The main materials used in the Portland cement include: clinker, Gypsum, limestone, slag, slag and vanadium-titanium slag;

[0052] The preparation method of P.S.A32.5 cement, the specific operation steps are:

[0053] Step 1: Purchase clinker, gypsum, limestone, slag and vanadium-titanium slag;

[0054] Step 2: Take the above-mentioned raw materials in proportion, mix them into the mill according to 44% of clinker, 6% of gypsum, 8% of limestone, and 42% of slag, and the gypsum is ordinary desulfurized gypsum;

[0055] Step 3: Add liquid grinding aid mainly composed of triethanolamine in the grinding process, the mixing ratio is 0.035-0.045%, and the cement ratio is controlled at 400-430 to obtain P.S.A32.5 cement;

[0056] Step 4: P.S.A32.5 cement enters the cement silo and leaves the warehousing, or leaves the factory ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com