Variable-frequency wind supply device for rail transit vehicle

A technology for rail transit vehicles and air supply devices, which is applied to vehicle components, air treatment devices, transportation and packaging, etc. It can solve the problems of reduced air quality of compressed air, affecting the service life of adsorbents, and limited processing capacity of single-tower dryers. , to achieve the effect of meeting the requirements of advanced repair programs, improving versatility, and strong environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

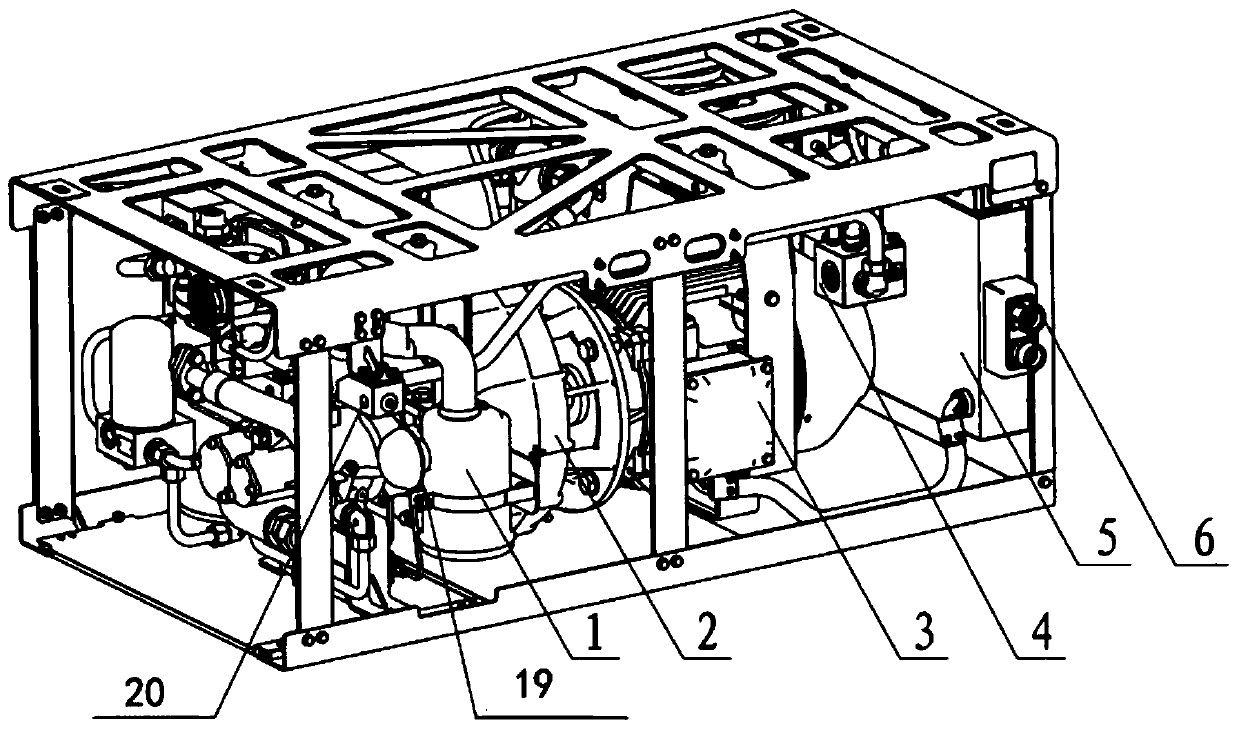

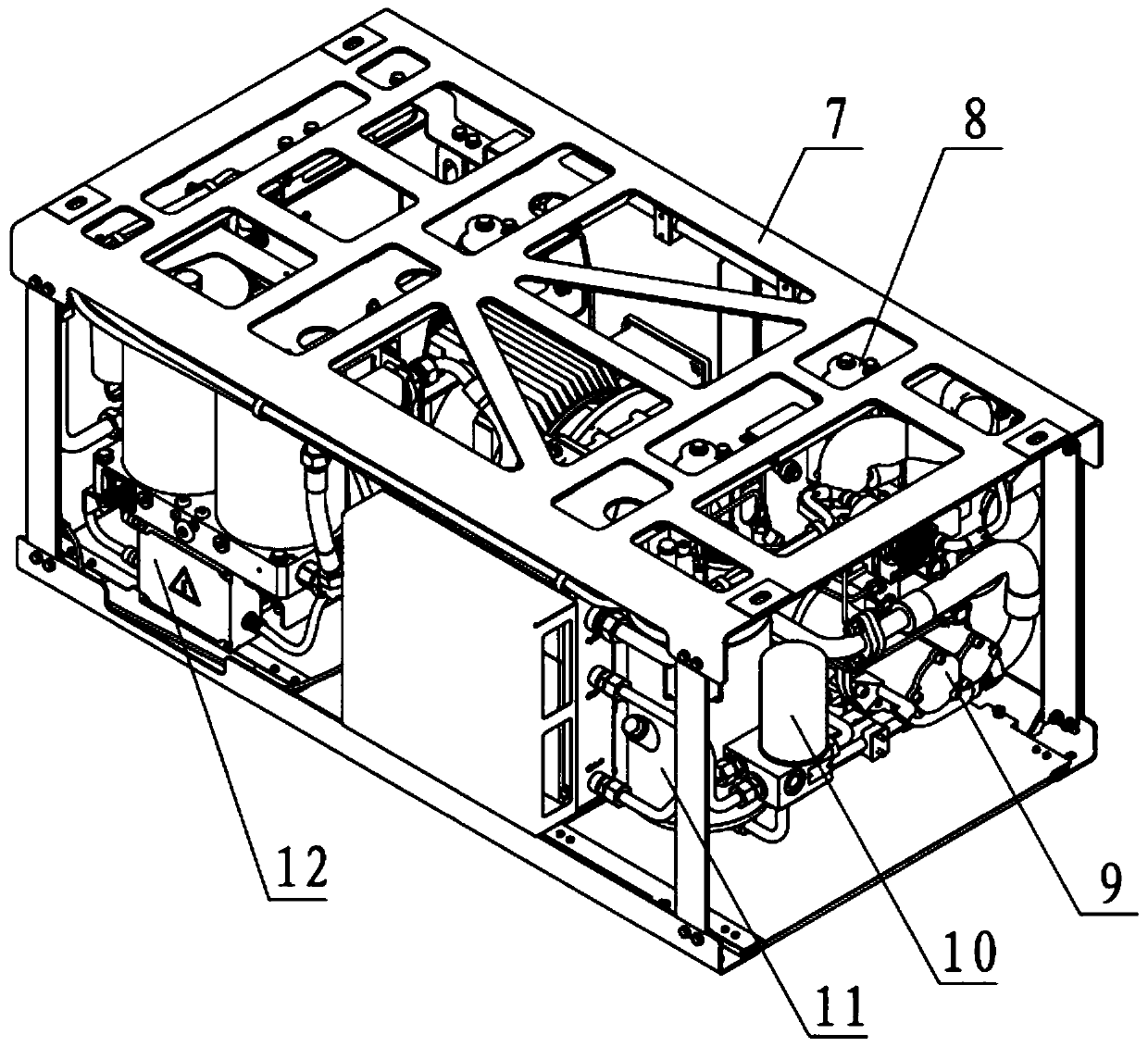

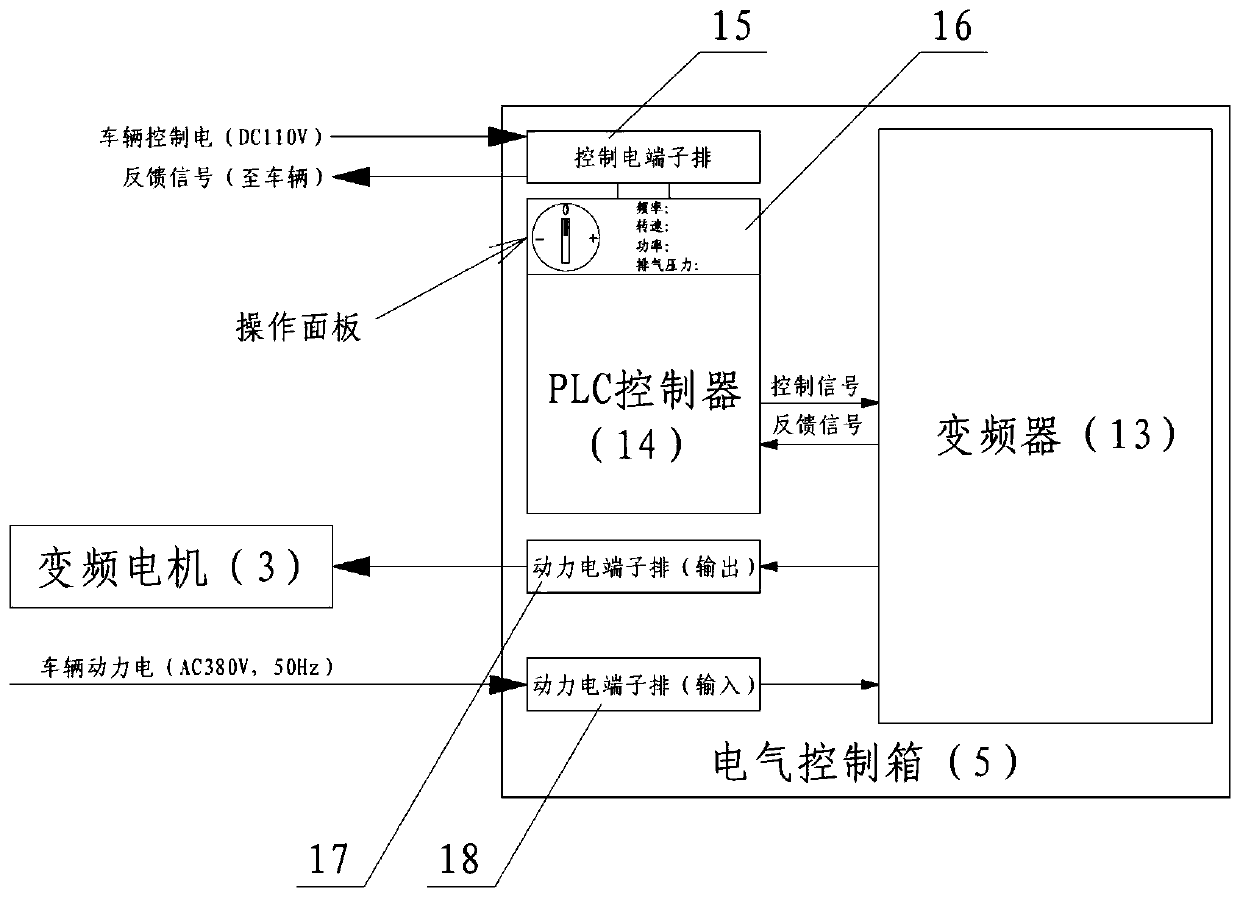

[0044] Such as figure 1 and 2 As shown, a frequency conversion air supply device for rail transit vehicles includes a hoisting frame 7, an electrical control box 5, an integrated air post-processing device 12, an outlet pressure maintaining valve 4, and a screw compressor. The screw compressor includes an air filter 1 , a screw host 9 , an oil-gas separation tank 11 , an oil filter 10 , an air cooling system 2 , and an inverter motor 3 . The hoisting frame 7 is installed on the bottom of the vehicle, and the screw compressor is connected with the hoisting frame 7 through an elastic shock absorber 8, which can prevent the vibration from being transmitted to the vehicle. The air supply device is electrically connected to the vehicle through the electrical connector 6 . The variable frequency motor 3 drives the screw host 9 and the air coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com