Thawing device

A technology for thawing chambers and components, applied in the field of thawing devices, can solve problems such as adjusting water vapor exhaust volume, and achieve the effects of improving exhaust efficiency, reducing size, and improving exhaust efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, embodiments of the present invention will be specifically described with reference to the drawings. It should be noted that the following embodiments are merely preferred examples in nature, and are not intended to limit the scope of the present invention, the applicable objects of the present invention, or the application of the present invention.

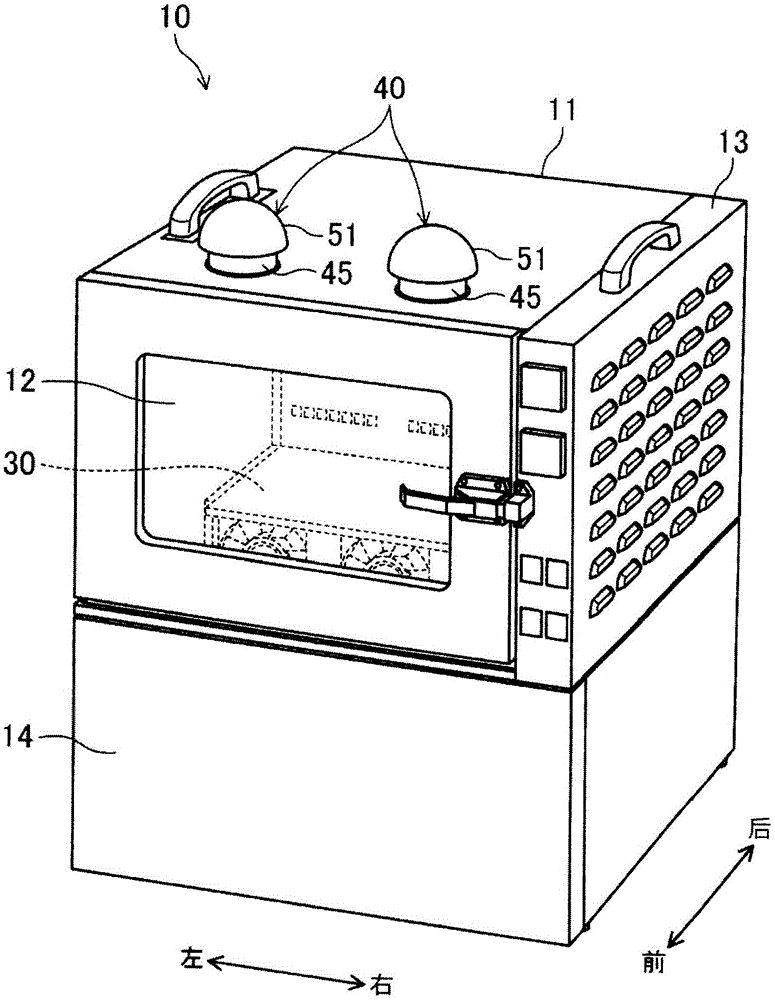

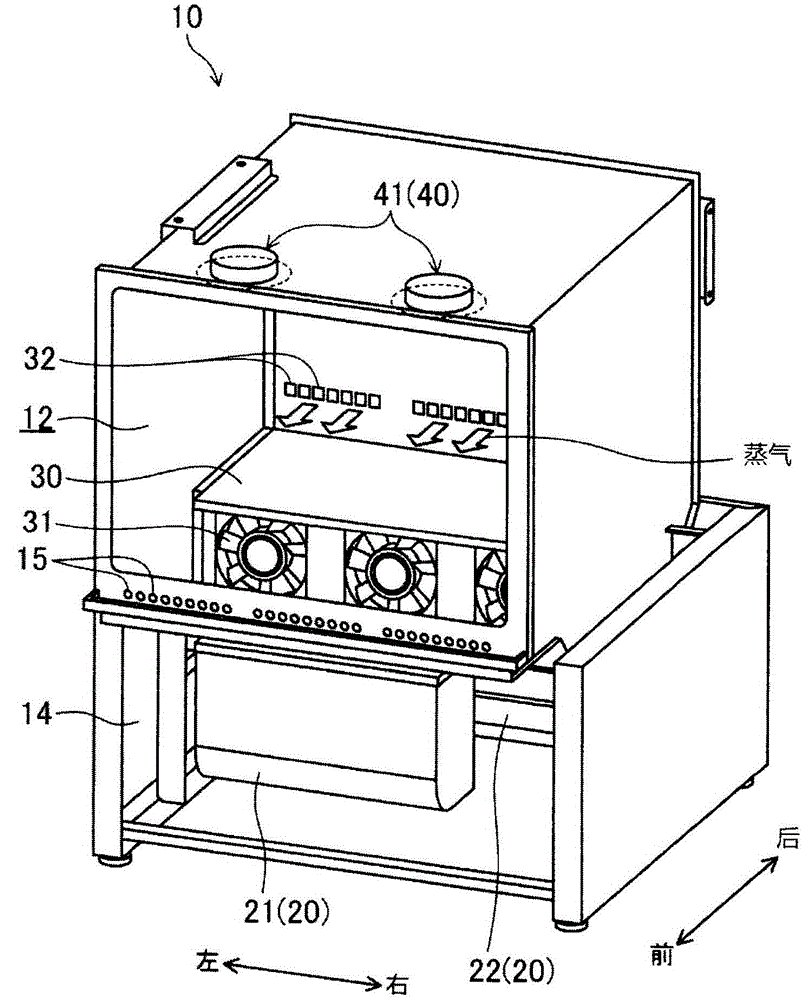

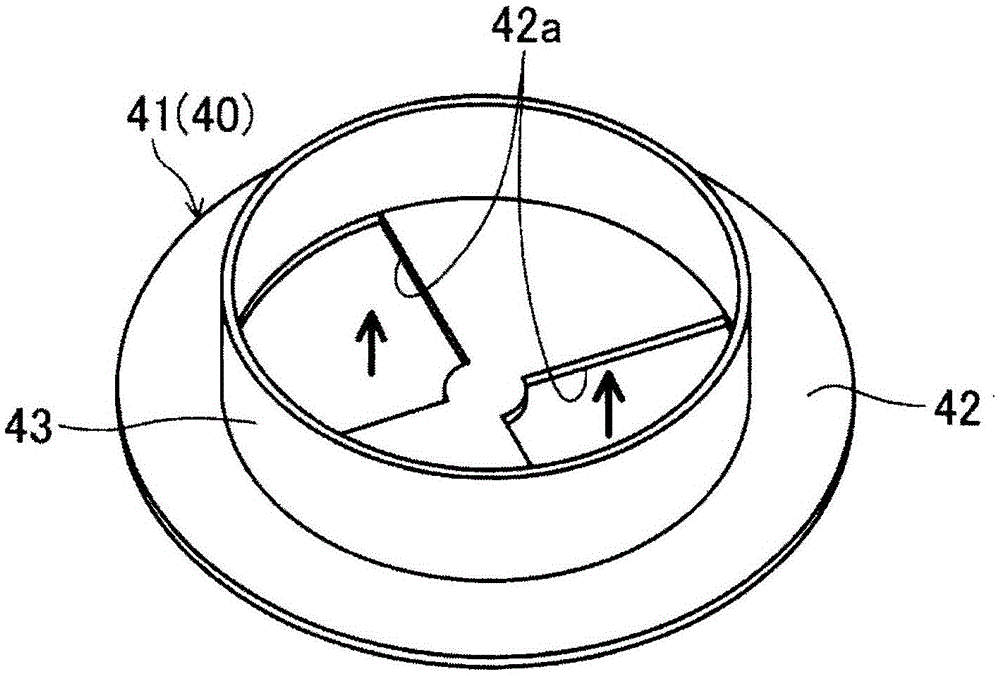

[0026] Such as figure 1 with figure 2 As shown, the thawing device 10 of this embodiment is a device for thawing objects to be thawed using latent heat of steam (hereinafter also referred to as water vapor). The thawing device 10 includes a substantially rectangular housing 11 having a thawing chamber 12 inside, and a steam generating mechanism 20 .

[0027] The defrosting chamber 12 is formed in substantially the upper half of the cabinet 11 , and the lower half of the cabinet 11 serves as the steam generation chamber 14 . On the upper half of the cabinet 11 , the right side of the thawing chamber 12 is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com