An integrated hybrid electrical cabinet that can adjust exhaust volume based on calorific value

An integrated technology with exhaust volume, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, photovoltaic power generation, etc., can solve the problems of heating of electrical components and uneven heat dissipation effect of electrical cabinets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

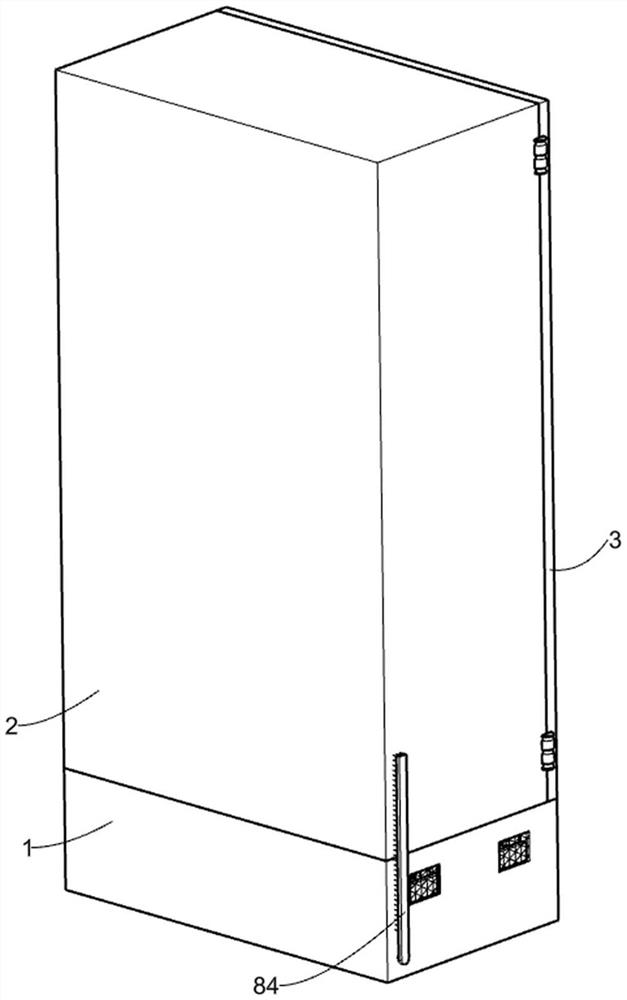

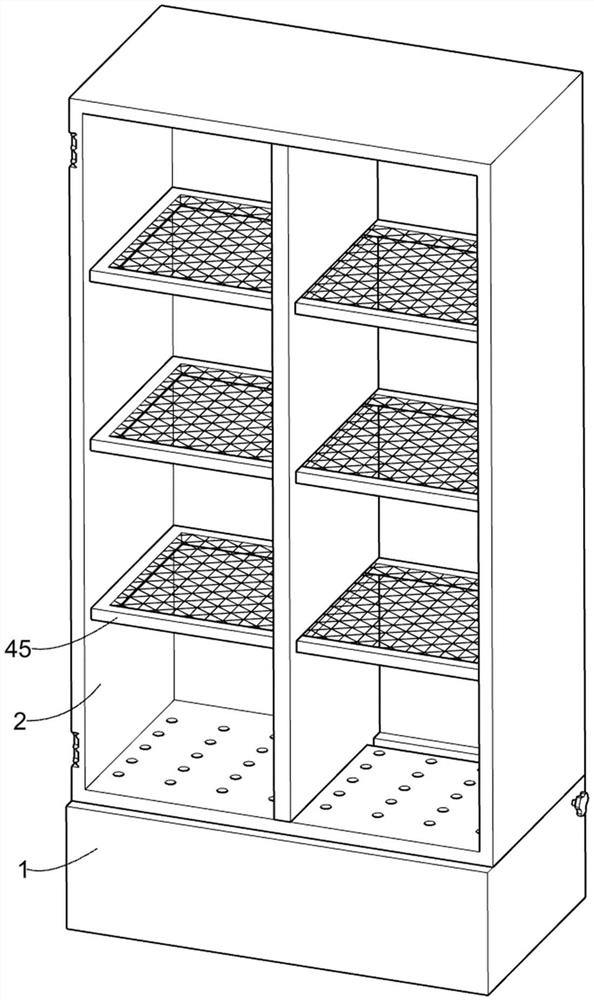

[0034] An all-in-one hybrid electrical cabinet that can adjust the exhaust volume based on the calorific value, such as Figure 1-15 As shown, it includes a bottom frame 1, a box body 2, a cover plate 3, an adjustment assembly 4, an air inlet expansion assembly 5, a speed change assembly 6 and an air extraction assembly 7. The bottom frame 1 has two exhaust ports, and the bottom frame 1 The box body 2 is fixedly installed on the top, and the bottom of the box body 2 has a plurality of heat dissipation holes. The box body 2 is connected with a cover plate 3 through hinges. The adjustment component 4 for adjustment is arranged on the box body 2, and the air inlet expansion component 5. It is slidably connected in the bottom frame 1, the speed change assembly 6 is arranged on the inner bottom of the bottom frame 1, and the inner wall of the bottom frame 1 is fixedly installed with an air extraction assembly 7 for extracting the hot air generated by the internal electrical componen...

Embodiment 2

[0042] On the basis of Example 1, as Figure 11 , Figure 16 As shown, it also includes a cleaning assembly 8, the speed change assembly 6 is provided with a cleaning assembly 8, and the cleaning assembly 8 is used to scrape off the sticky dust on the exhaust port on the bottom frame 1, and the cleaning assembly 8 includes a The second transmission shaft 801 , the universal joint transmission shaft 802 , the drive plate 81 , the connecting shaft 82 , the slotted swing rod 83 and the brush plate 84 , the inclined surface guide plate 61 is rotatably connected with the second transmission shaft 801 , the second transmission shaft The universal drive shaft 802 is fixed on the 801, the universal drive shaft 802 away from the second drive shaft 801 is welded to one end of the first drive shaft 612, and the end of the second drive shaft 801 away from the universal drive shaft 802 is welded with a drive plate 81. , the bottom frame 1 is rotatably connected with a connecting shaft 82,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com