Heat-sensitive paper slitting machine

A technology of slitting machine and thermal paper, which is applied in metal processing, winding strips, thin material processing, etc. It can solve the problems of lack of automation and achieve the effect of improving fluency, improving stability and avoiding slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

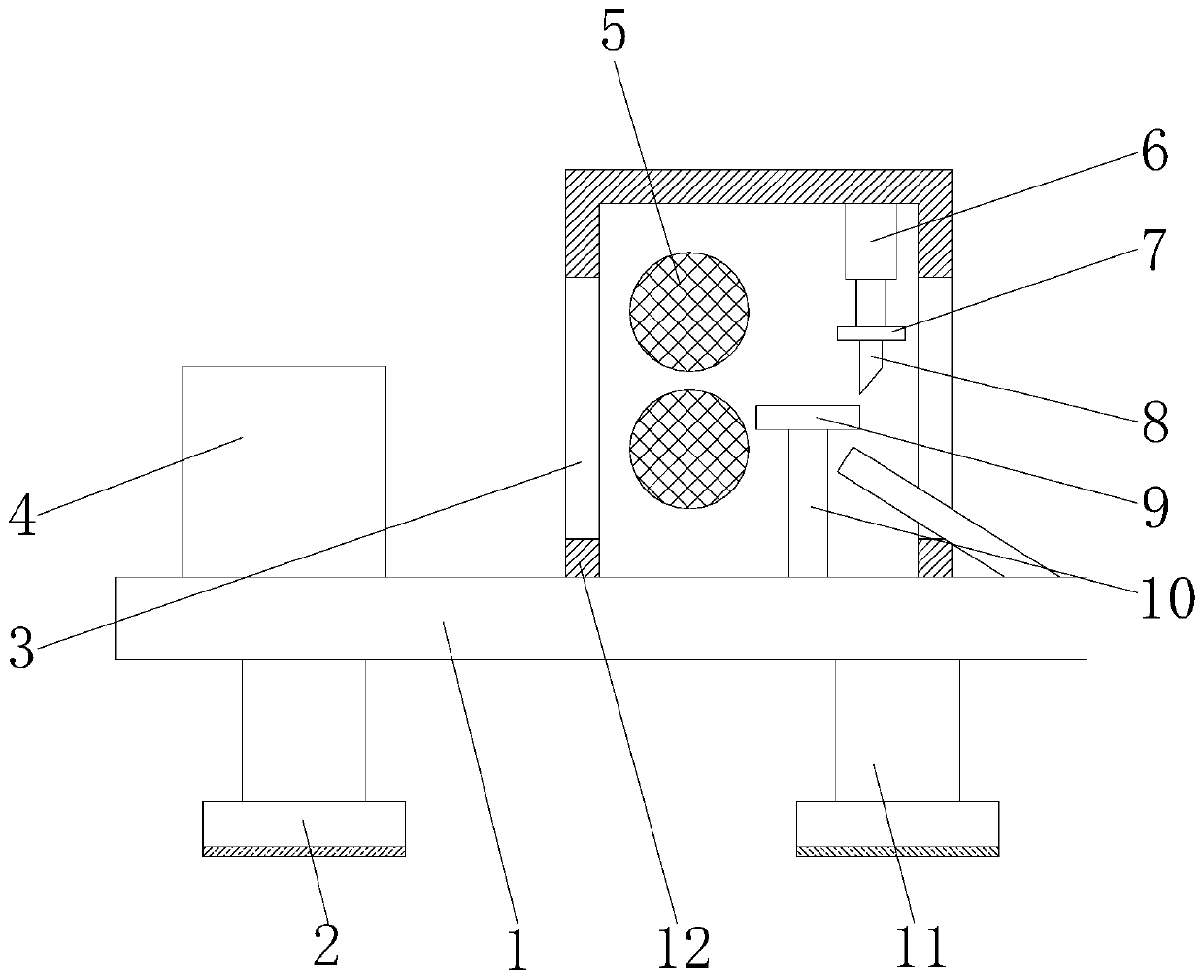

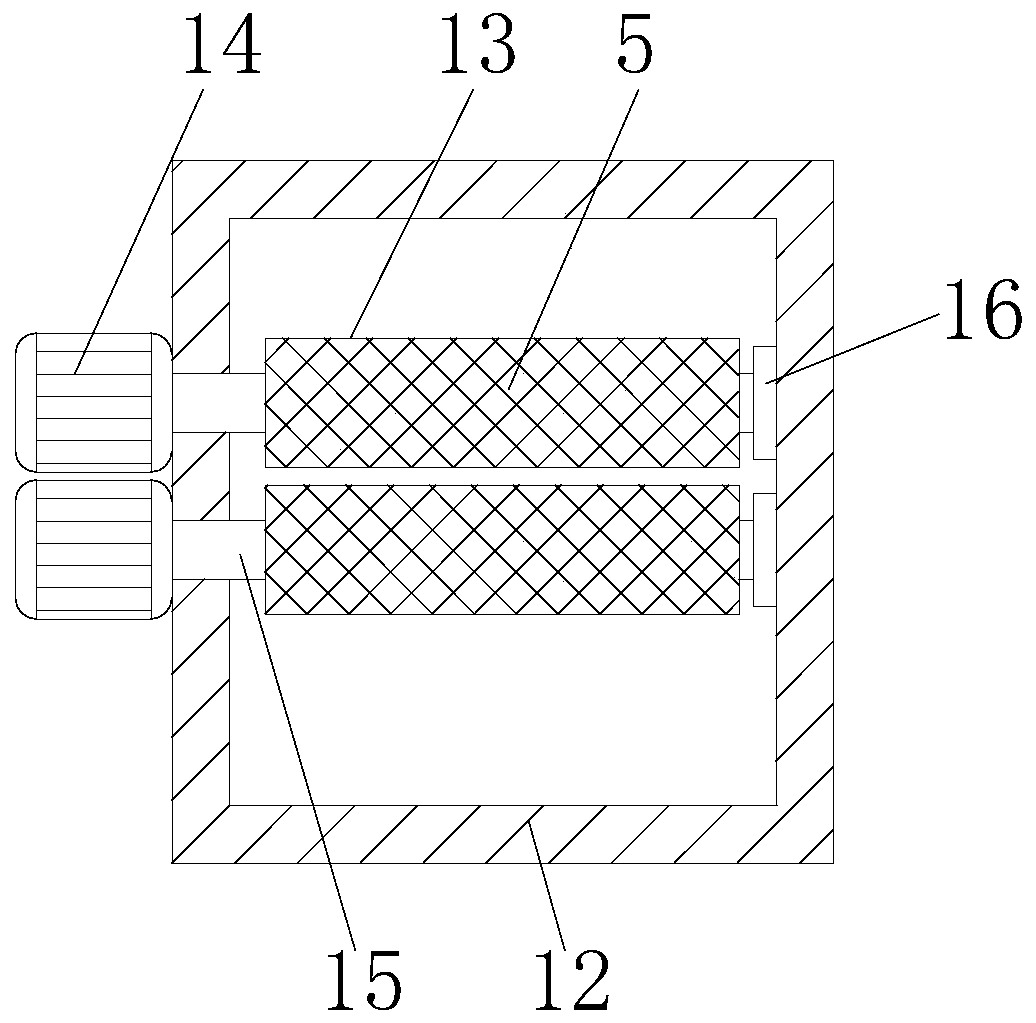

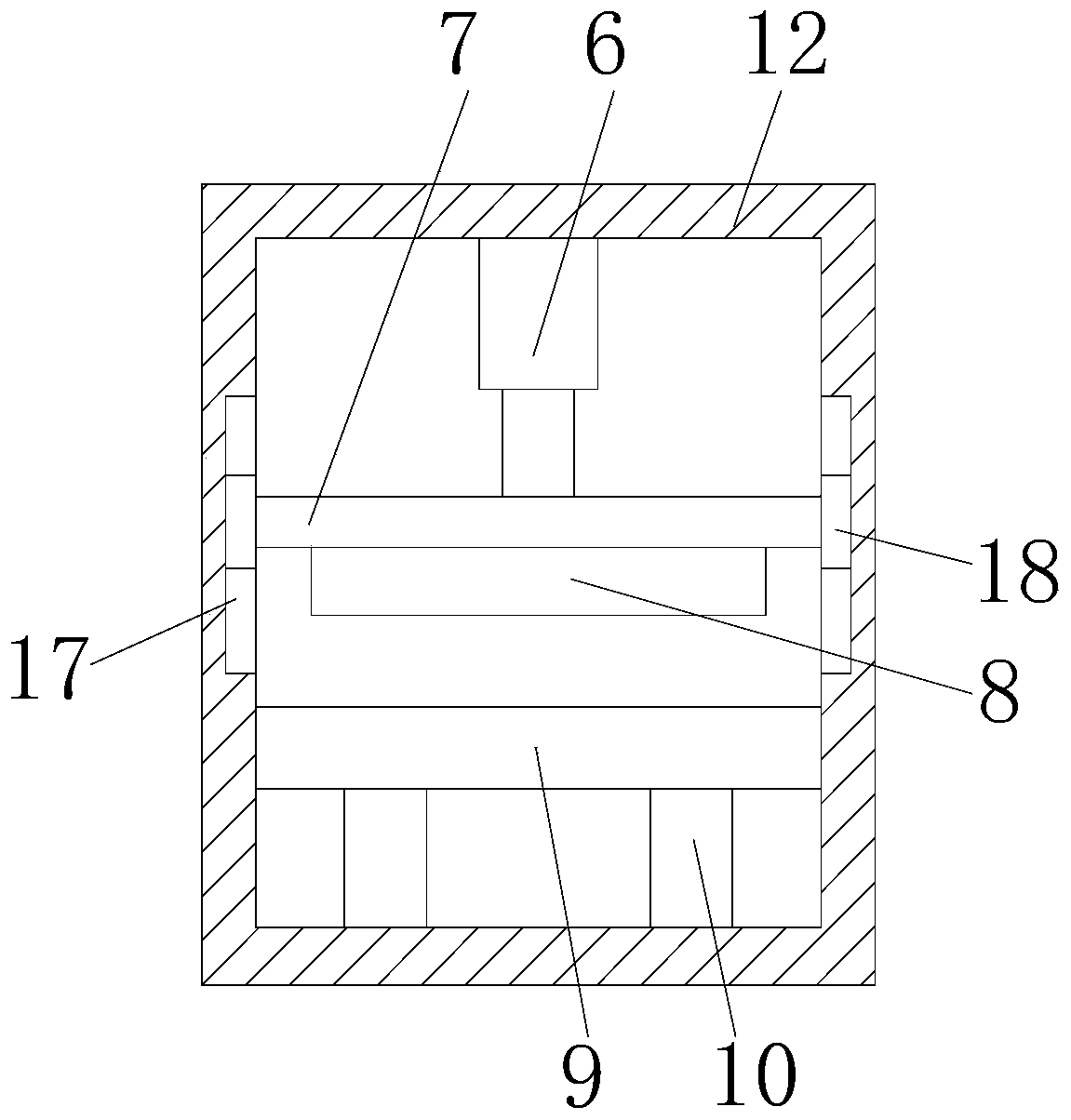

[0023] see Figure 1-4 , a heat-sensitive paper slitting machine, comprising a working plate 1, a slitting frame 12 is fixedly connected to the right side of the top of the working plate 1, and a speed-regulating motor 14 is fixedly connected to the top and bottom of the slitting frame 12 back. The output end of motor 14 runs through slitting frame 12 and is fixedly connected with rotating rod 15, and the front of rotating rod 15 is movably connected with first bearing 16, and the front of first bearing 16 is fixedly connected with the junction of slitting frame 12, and rotating rod The surface of 15 is fixedly connected with movable roller 5, and the right side of slitting frame 12 cavity top is fixedly connected with electric telescopic rod 6, and the output end of electric telescopic rod 6 is fixedly connected with mounting bracket 7, and the bottom of mounting frame 7 is fixedly connected with Cutting knife 8, the inner cavity of slitting frame 12 is provided with placemen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com