Device for automatically opening and closing flexible bellow of machine tool cover

An automatic opening and closing, elastic skin technology, applied in the field of CNC machine tools, can solve the problems of high drive synchronization requirements, elastic skin cavity span jamming, large space occupied by protective doors, etc., to achieve large-span space design, Large door opening width, avoiding the effect of motion jamming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

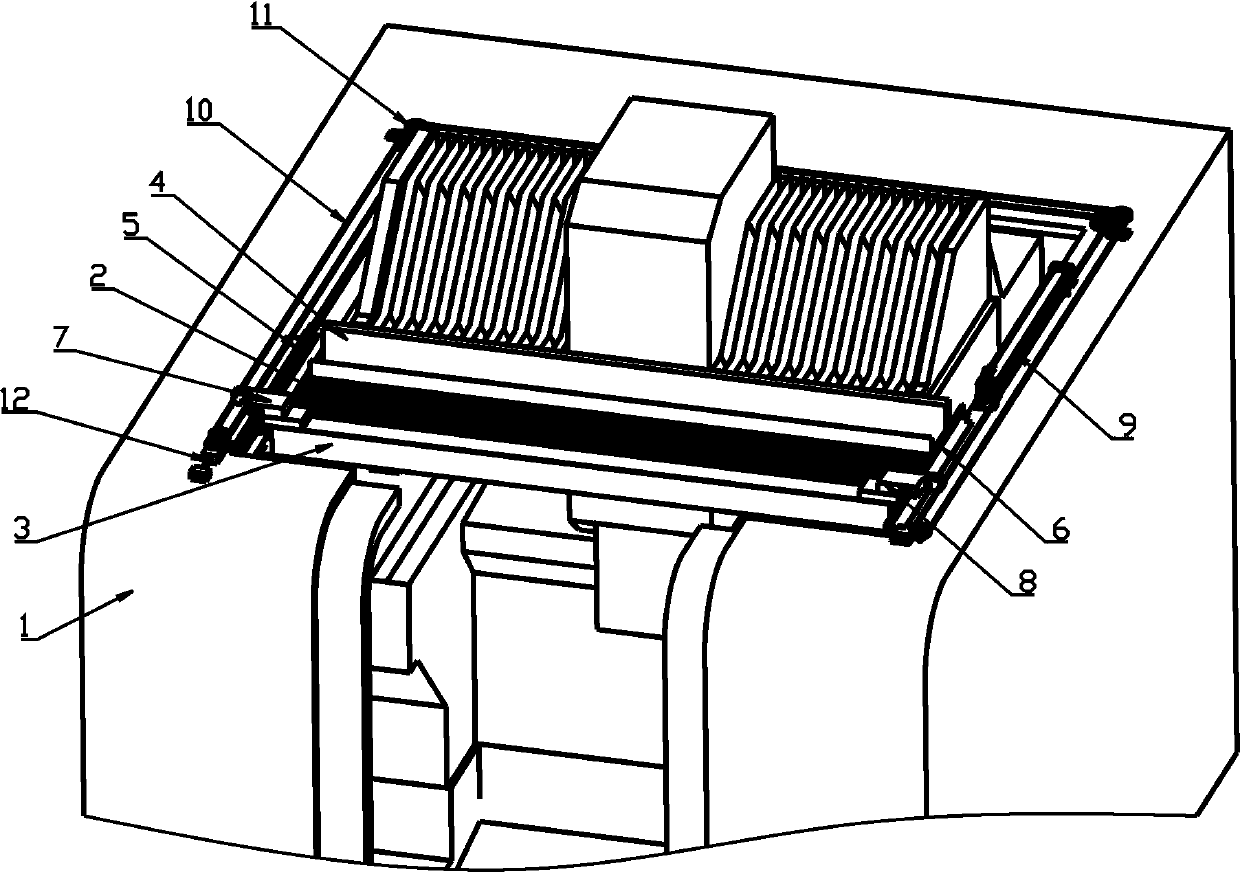

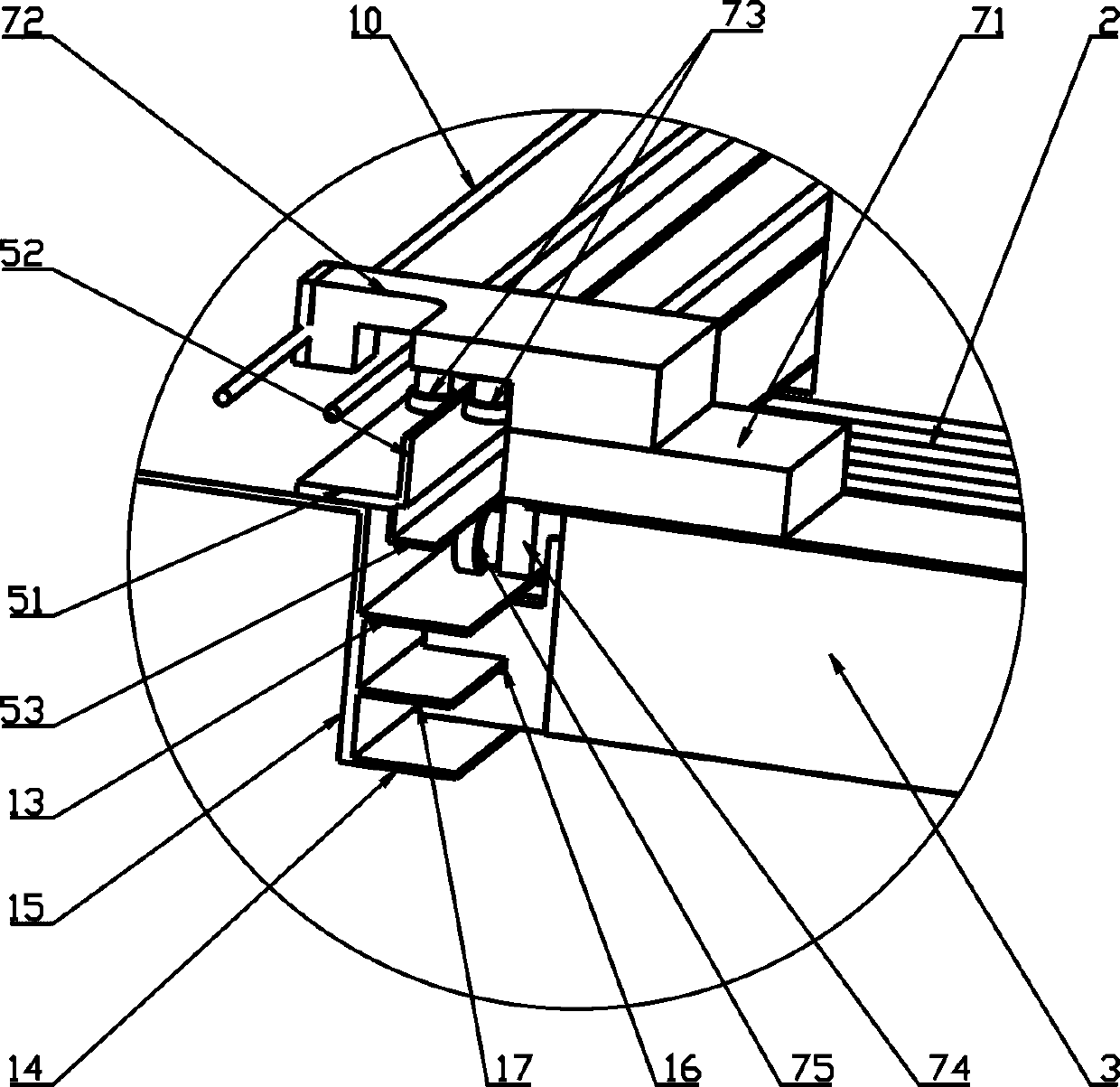

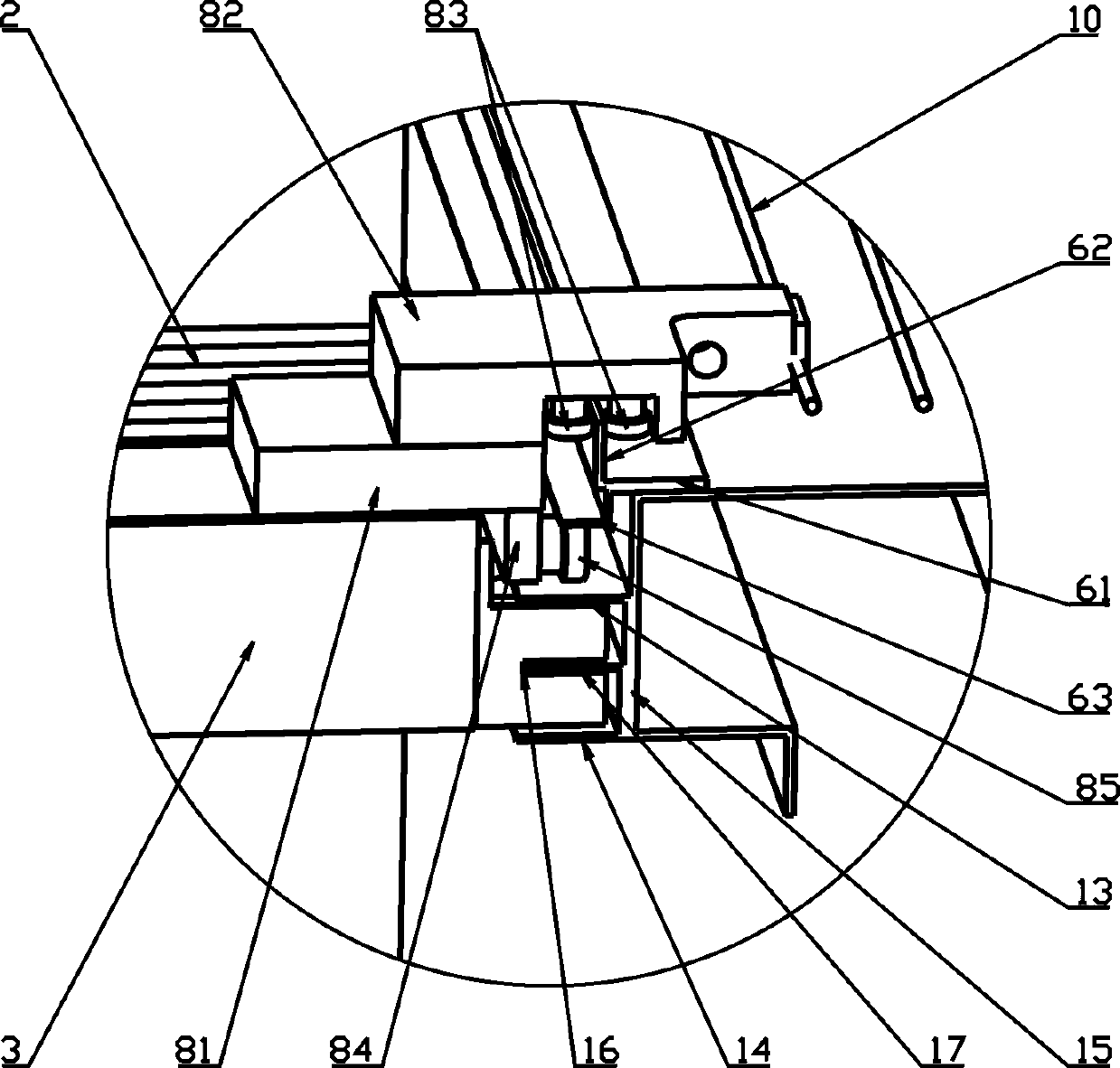

[0019] Such as figure 1 As shown, the automatic opening and closing device of an elastic bellows of a machine tool guard of the present invention consists of a machine guard 1, an elastic bellows 2, a front bracket 3, a rear bracket 4, a guide sheet metal 5, a guide sheet metal 6, a sliding Device 7, sliding device 8, cylinder 9 and wire rope circuit 10 are formed.

[0020] The top of the machine tool cover 1 is provided with a hoisting opening, and the rear side edge of the hoisting opening is composed of the machine head shield protruding from the machine tool cover 1 and the X-axis protection device; And guide sheet metal 6; the front end of the elastic bellows 2 is fixedly connected with the front bracket 3, and the rear end is fixedly connected with the rear bracket 4. The front bracket 3 is installed between the guide sheet me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com