Method for removing dust on surface of steel wire rope for building hoist

A cleaning method and wire rope technology are applied in the field of hoists, which can solve the problems of inability to clean the wire rope, the influence of the hoist operation, the breakage of the wire rope, etc., and achieve the effect of easy cleaning and treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

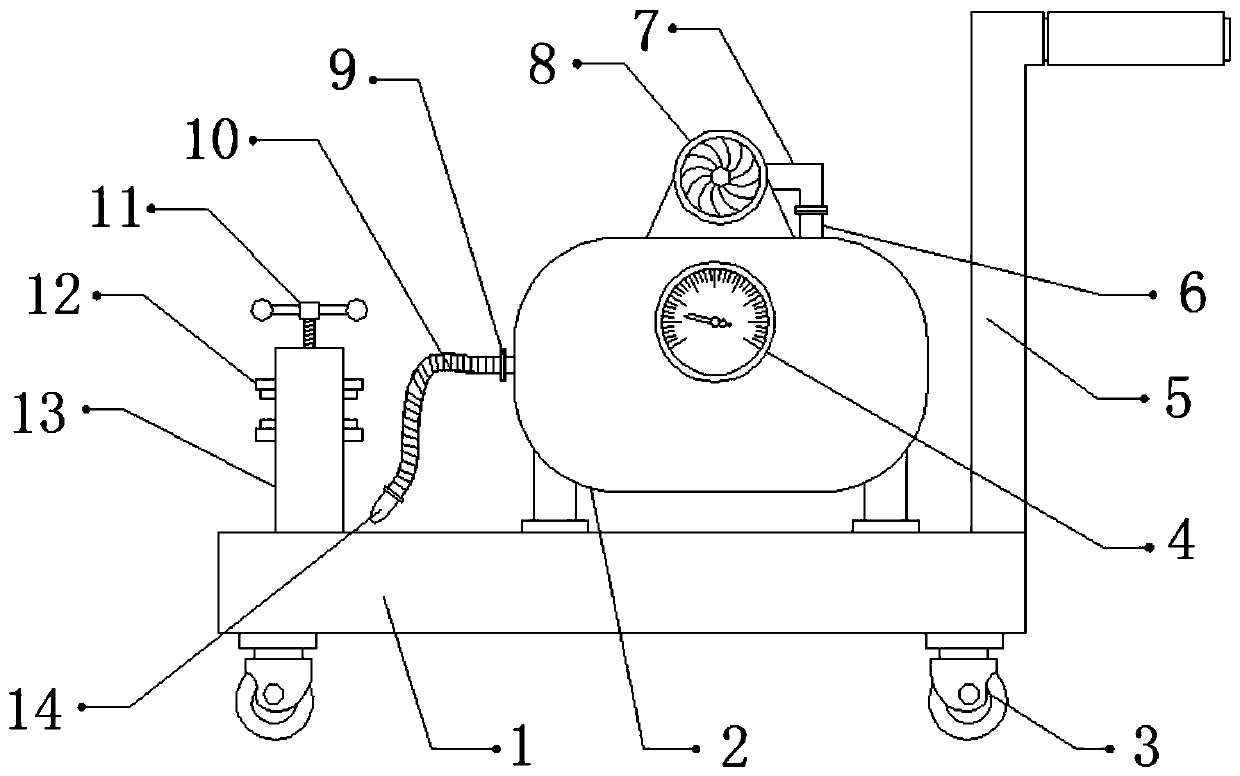

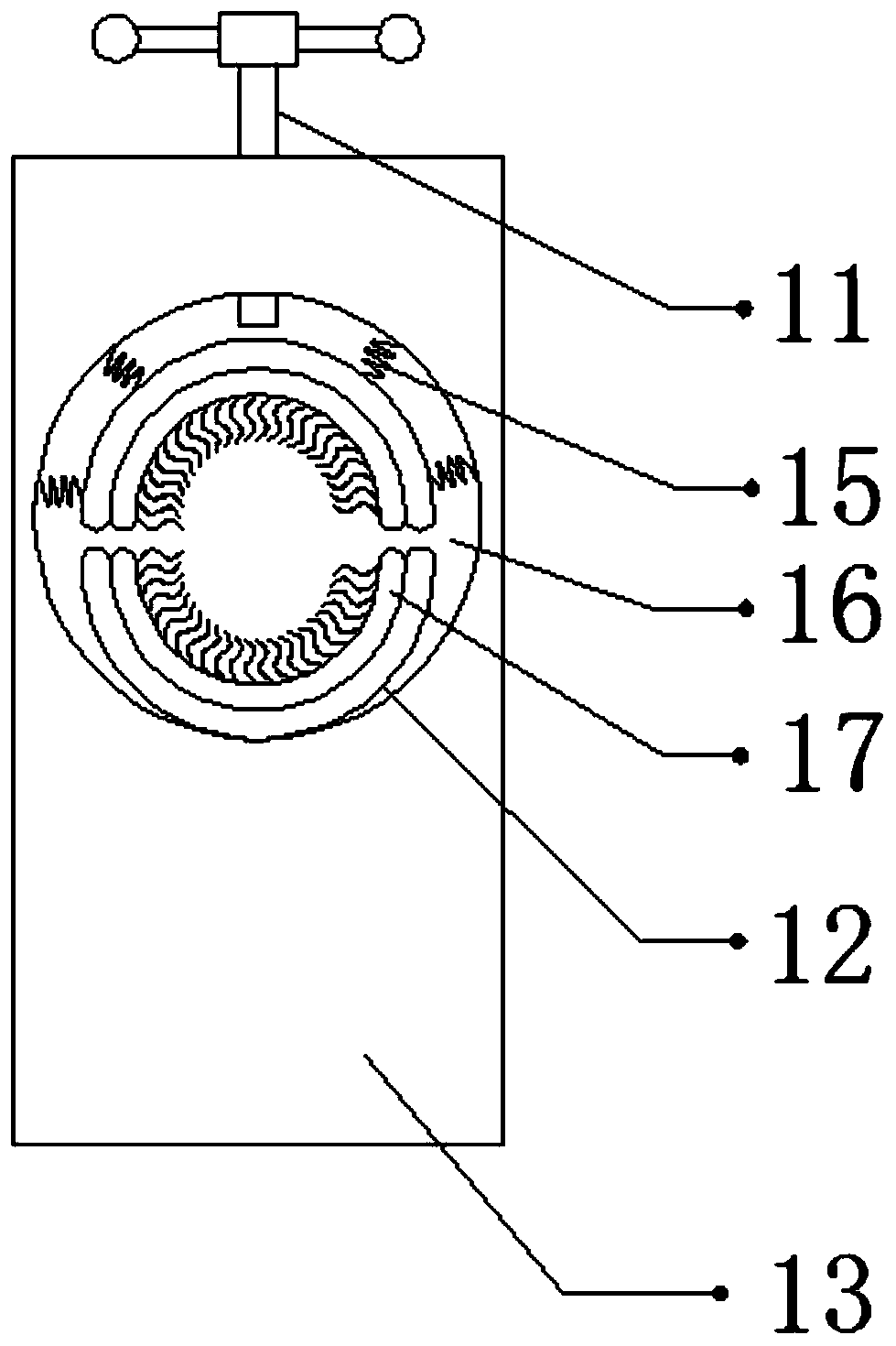

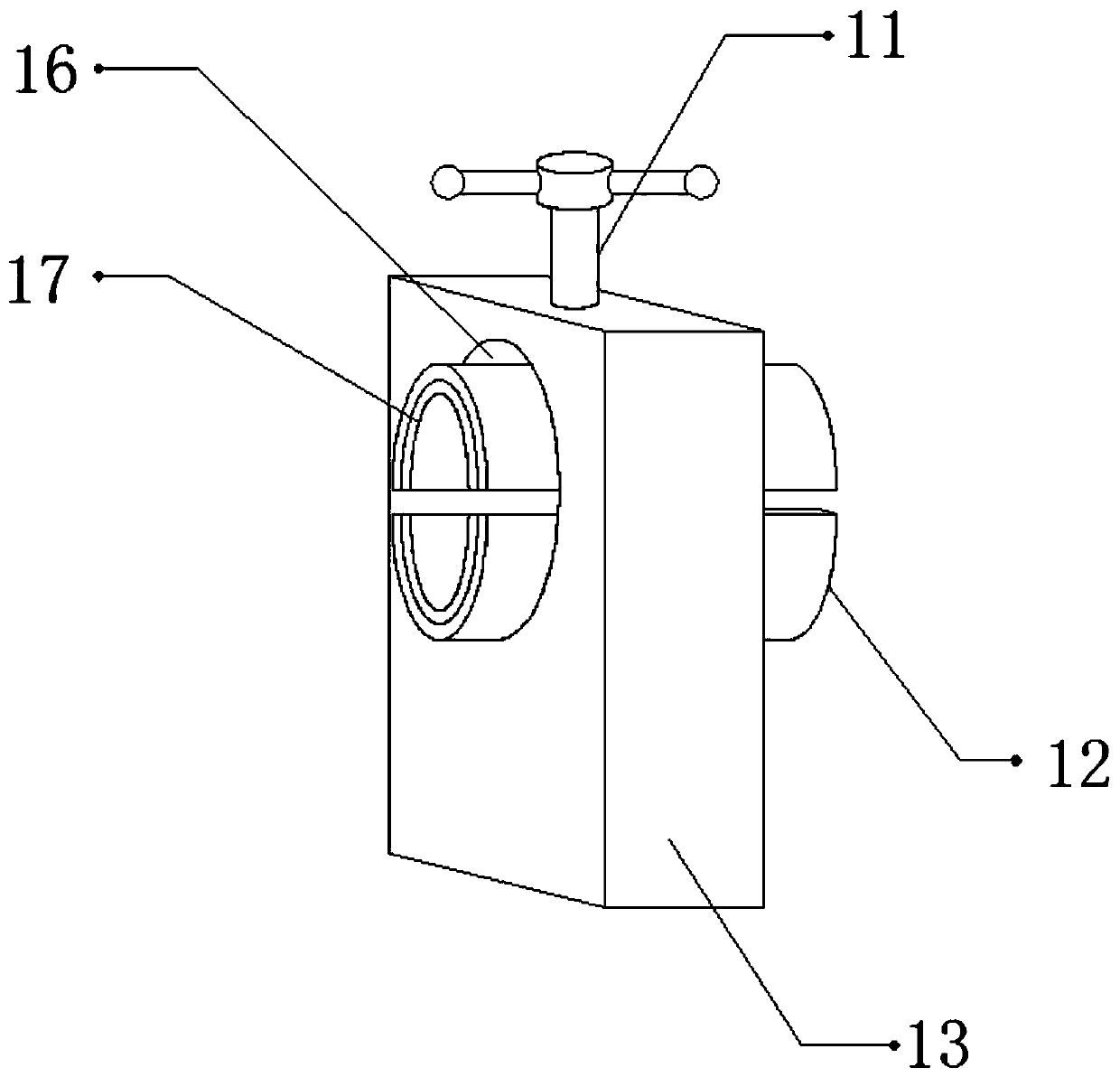

[0020] refer to Figure 1-3 , an auxiliary cleaning device for a building hoist, comprising a fixed seat 1, one side of the outer wall of the top of the fixed seat 1 is connected with a cleaning plate 13 by bolts, and the outer wall of one side of the cleaning plate 13 is provided with a cleaning port 16, and the top of the cleaning port 16 The inner wall is connected with a spring 15 by bolts, and the bottom outer wall of the spring 15 and the bottom inner wall of the cleaning port 16 are all connected with a splint 12 by bolts, and the outer walls on the opposite side of the two splints 12 are connected with a cleaning cotton 17 and a cleaning port 16 by bolts. There is a threaded opening on the top inner wall, and the inner wall of the threaded opening is threadedly connected with a threaded rod 11, one side of the outer wall of the top of the fixing base 1 is connected with an air pump 2 by bolts, and one side of the outer wall of the top of the air pump 2 is provided with ...

Embodiment 2

[0024] refer to Figure 4-5 , an auxiliary cleaning device for a construction winch. Compared with Embodiment 1, the outer wall of one side of the air gun 14 is connected with a handle 18 by bolts, and the outer wall of the handle 18 is engraved with anti-skid lines.

[0025] Working principle: When in use, the device is moved to the side of the winch by the moving wheel 3. After the movement is completed, the device is fixed by the brake pads. The fan 8 will absorb the outside air into the air pump 2 through the air duct 7, and the air pump 2 will The gas is discharged to the inside of the air gun 14 through the exhaust pipe 9 and the corrugated hose 10, and the handle 18 is held by hand so that the air gun 14 can clean the dust on the surface of the winch, and the steel wire rope is inserted into the cleaning port 16. The rod 11 makes the splint 12 clamp the steel wire rope, so that the steel wire rope is cleaned by the cleaning cotton 17, and the air pressure inside the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com