Method of producing clamping force for a vehicle produced by an automatic parking brake

A parking brake and clamping force technology, applied in the direction of brakes, brake types, and axial brakes, etc., can solve the problems of long tracking time of the controller and increased component load, and achieve small volume accommodation, reduced component load, and reduced component load. Effect of small residual braking torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

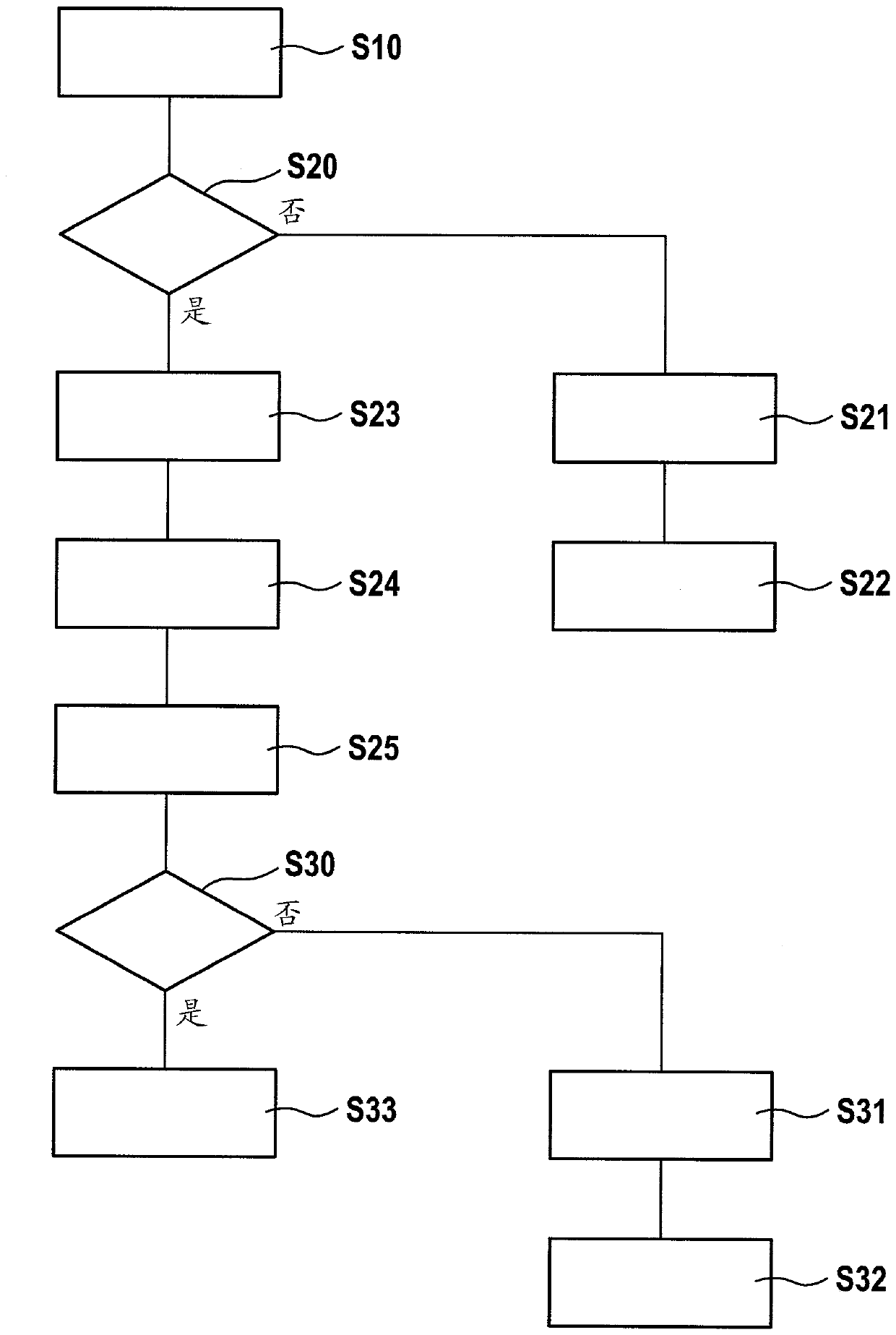

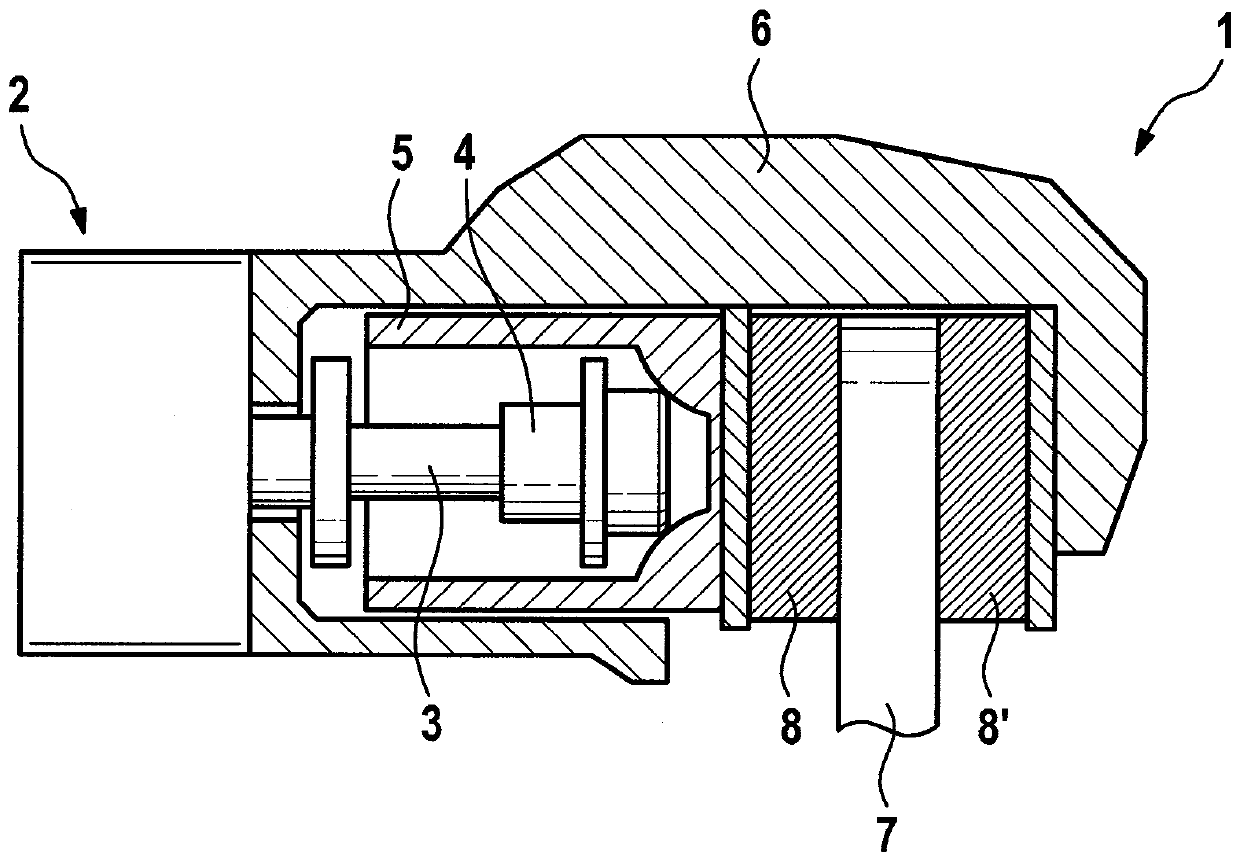

[0018] figure 1 A section is shown of a known automatic (automated) parking brake (parking brake) 1 for vehicles, which can exert a clamping force for immobilizing the vehicle by means of a brake motor 2 . The brake motor 2 is presently designed as an electric motor, which drives an axially mounted spindle 3 , in particular a spindle. On its end facing away from the brake motor 2 , the spindle 3 is equipped with a spindle nut 4 , which bears against the inner front or rear of the brake piston 5 . Spindle 3 , spindle nut 4 and brake piston 5 are mounted in a brake caliper 6 , which engages brake pads 7 in a caliper-like manner above. A brake friction layer 8 , 8′ is arranged on both sides of the brake pad 7 .

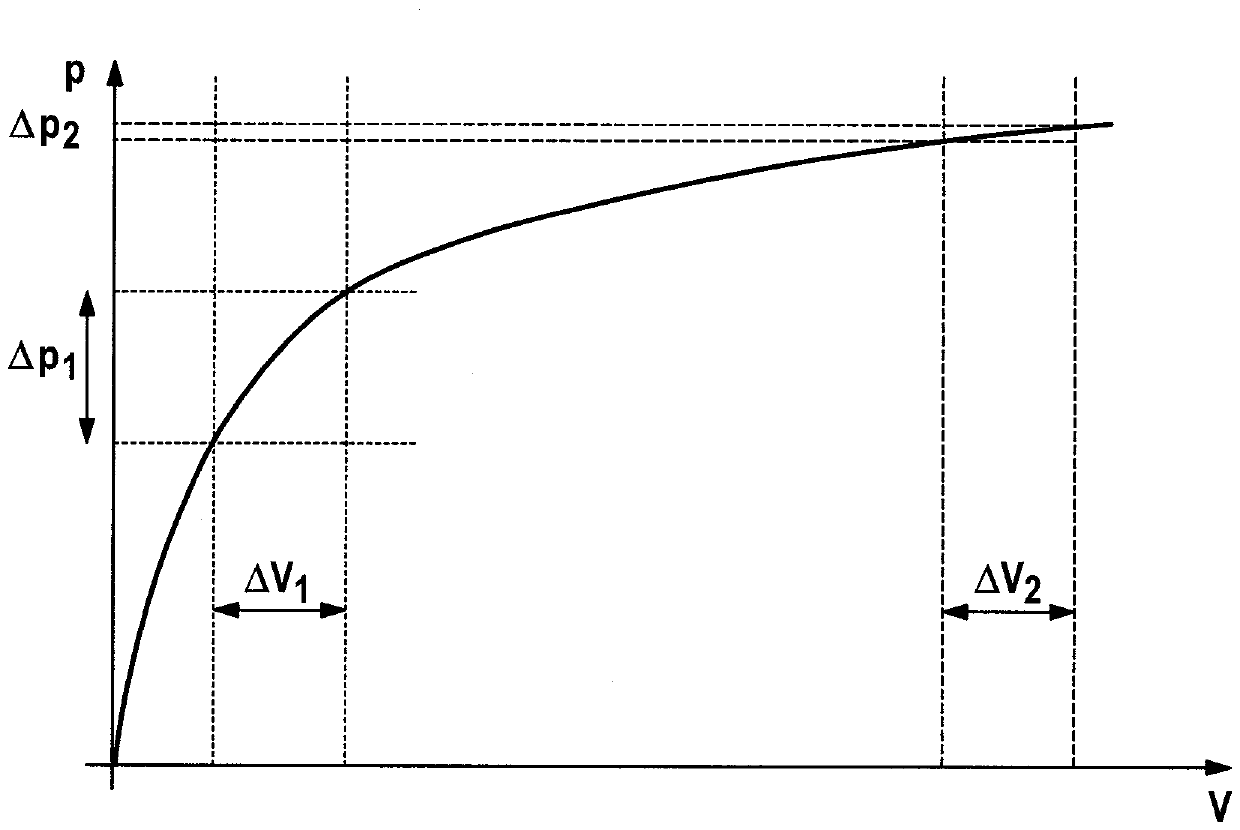

[0019] During the application process of the parking brake 1 , the spindle nut 4 is moved axially towards the brake piston 5 and the brake lining 7 by the rotation of the spindle 3 until a predetermined target clamping force is reached. In addition to the electromecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com