Stamp pestle equipment for moxa stick production

A technique for pounding and pestle and moxa sticks, which is applied in the field of pestle and pestle equipment for the production of moxa sticks, can solve the problems of turning over the leaves of moxa leaves, save manpower, prevent knocking damage, and improve the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

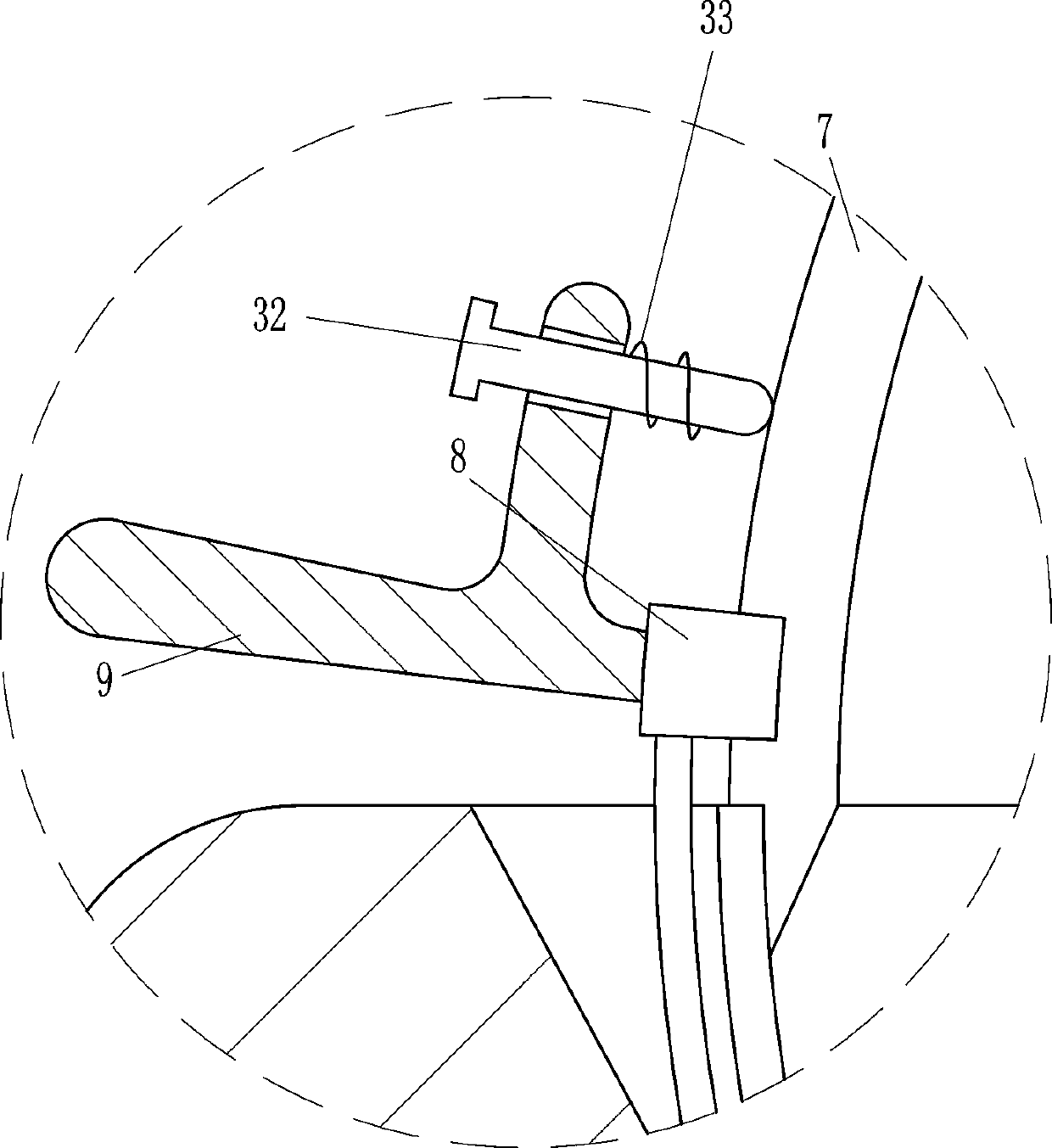

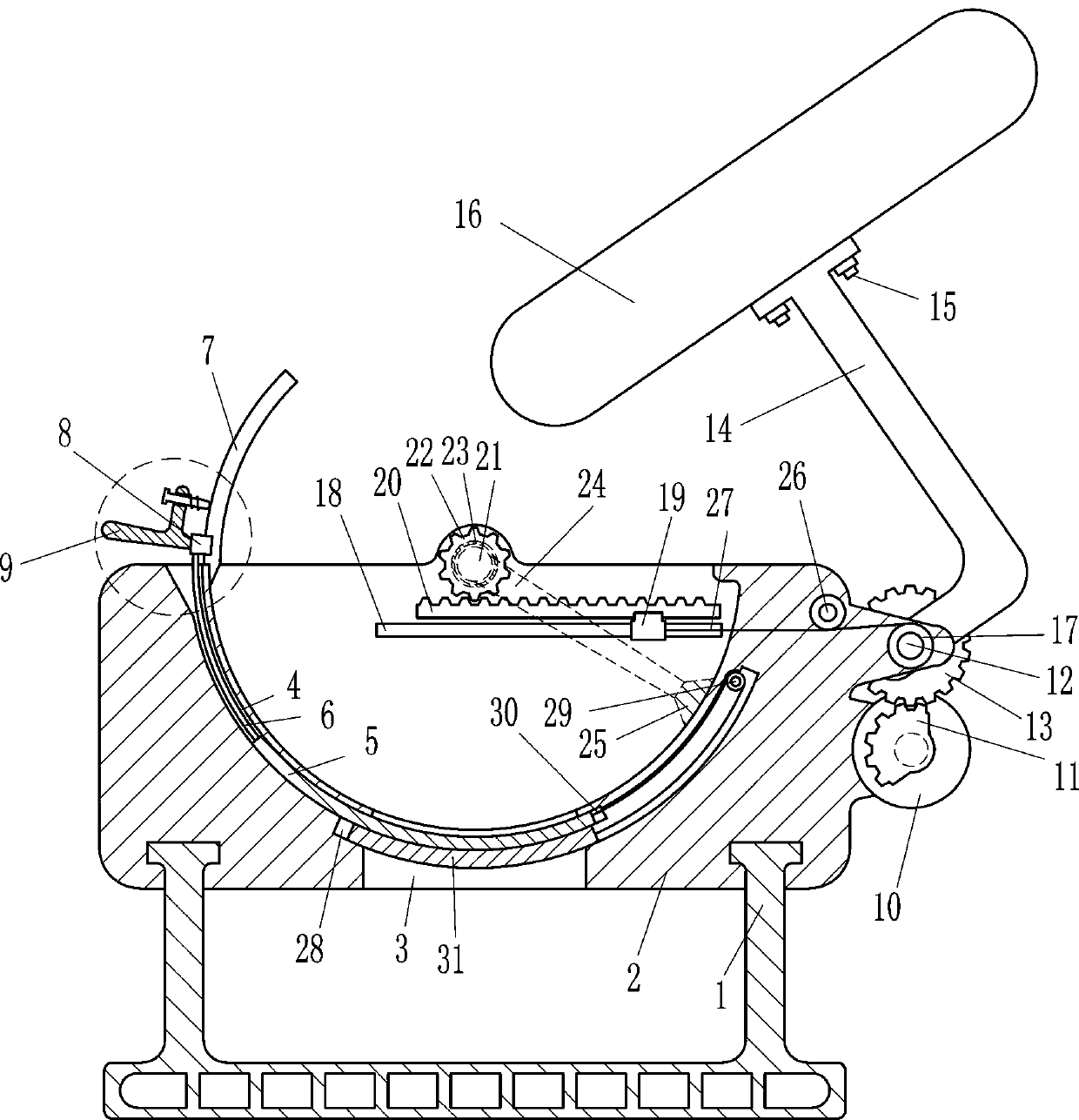

[0017] see figure 1 , the application provides a pestle equipment for moxa stick production, including a support 1, a stone mortar 2, a discharge device, a crushing device and a turning device, the upper part of the support 1 is equipped with a stone mortar 2, and the lower part of the stone mortar 2 is installed with a sliding method. Carry out the discharging device of discharging, stone mortar 2 right side is equipped with the crushing device that is carried out to crushing wormwood by swinging mode, and stone mortar 2 top is provided with the turning device that wormwood is stirred by rotating mode. Specifically, when it is necessary to use the equipment to crush the leaves of wormwood, pour the leaves of the leaves that need to be crushed into the stone mortar 2, and then the user controls the crushing device to start working, and the leaves of the leaves in the stone mortar 2 are crushed. When the device crushes the mugwort leaves, the smashing device drives the turning ...

Embodiment 2

[0020] see figure 1 , the crushing device includes a reduction motor 10, a sector gear 11, a rotating shaft 12, the first full gear 13, a swing lever 14, a fixing bolt 15 and a pestle 16, and the bottom right side of the stone mortar 2 is equipped with a reduction motor 10 through a bolt, and the speed reduction A sector gear 11 is connected to the output shaft on the front side of the motor 10, and a rotating shaft 12 is rotatably connected between the front and rear sides of the upper part of the right side of the mortar 2 through a bearing seat. The first full gear 13 is installed on the rotating shaft 12. The gear 13 is engaged with the sector gear 11, and the rotating shaft 12 is welded with a swing lever 14, and the swing lever 14 tail end is connected with a pestle 16 by a fixing bolt 15. Specifically, when crushing mugwort leaves, the user controls the reduction motor 10 to rotate counterclockwise, thereby driving the sector gear 11 to rotate counterclockwise, and then...

Embodiment 3

[0023] see figure 1, on the basis of Embodiment 1 and Embodiment 2, in order to make the equipment work more stably, it also includes a second pulley 29, a second pull wire 30 and an arc-shaped support plate 31, and the lower part of the mortar 2 has a second chute 28, the second chute 28 partially overlaps the first chute 4 in the vertical direction, the second chute 28 is slidably connected with an arc-shaped support plate 31, and the right part of the second chute 28 is provided with a second pulley 29 , the right side of the arc-shaped support plate 31 is connected with a second stay wire 30 , the second stay wire 30 bypasses the second pulley 29 , and the tail end of the second stay wire 30 is connected to the arc-shaped baffle 5 . Specifically, when the user needs to take out the crushed mugwort leaves, the arc-shaped baffle plate 5 moves to the upper left, and the second pull wire 30 drives the arc-shaped support plate 31 to move to the upper right, thereby opening the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com