A new storage and conveying device for wood-plastic panels

A conveying device and plate technology, applied in transportation and packaging, conveyor objects, etc., can solve the problems of large labor input, easy damage to plates, and low efficiency of loading plates, so as to improve work efficiency, ensure production safety, and reduce labor input. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

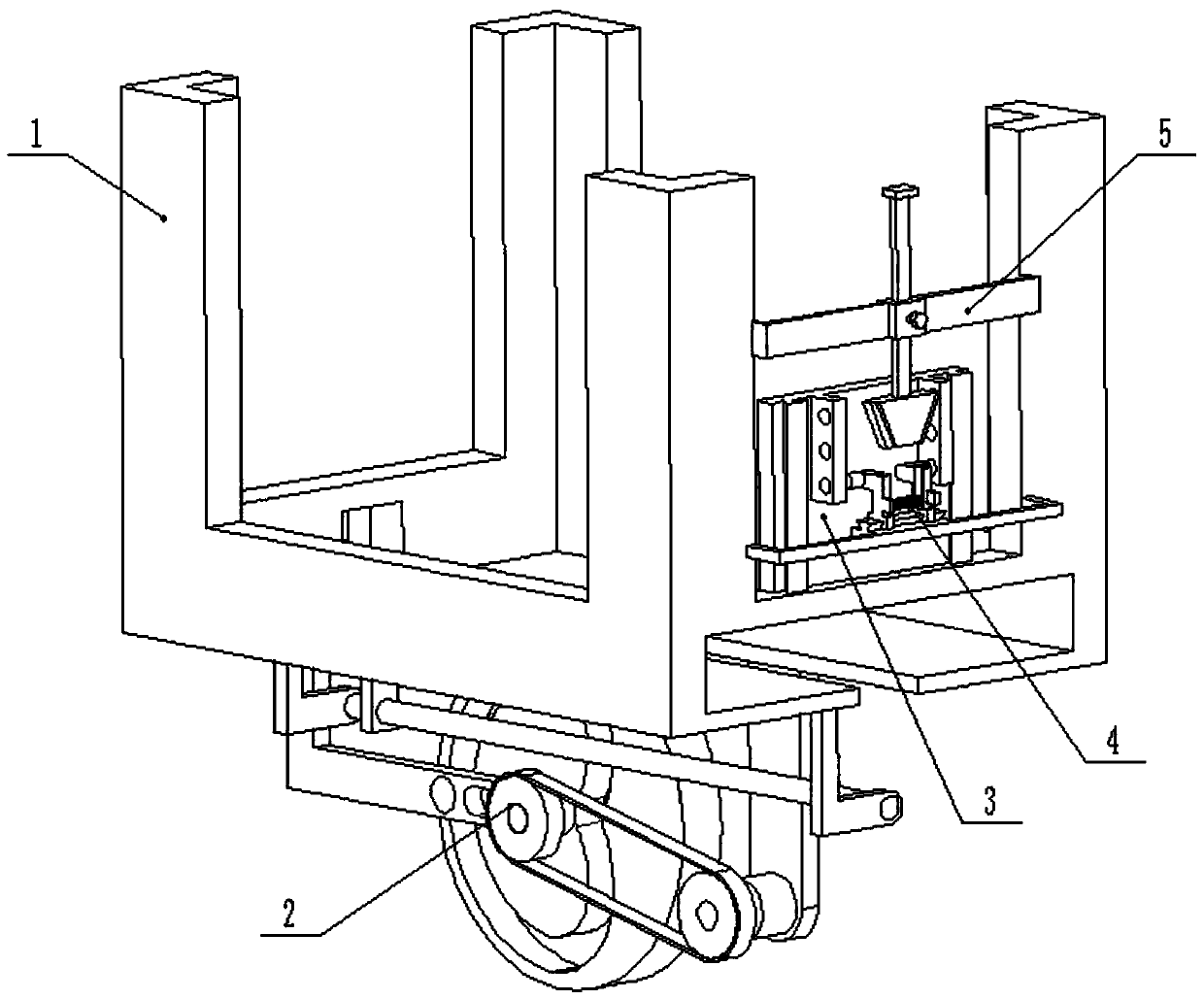

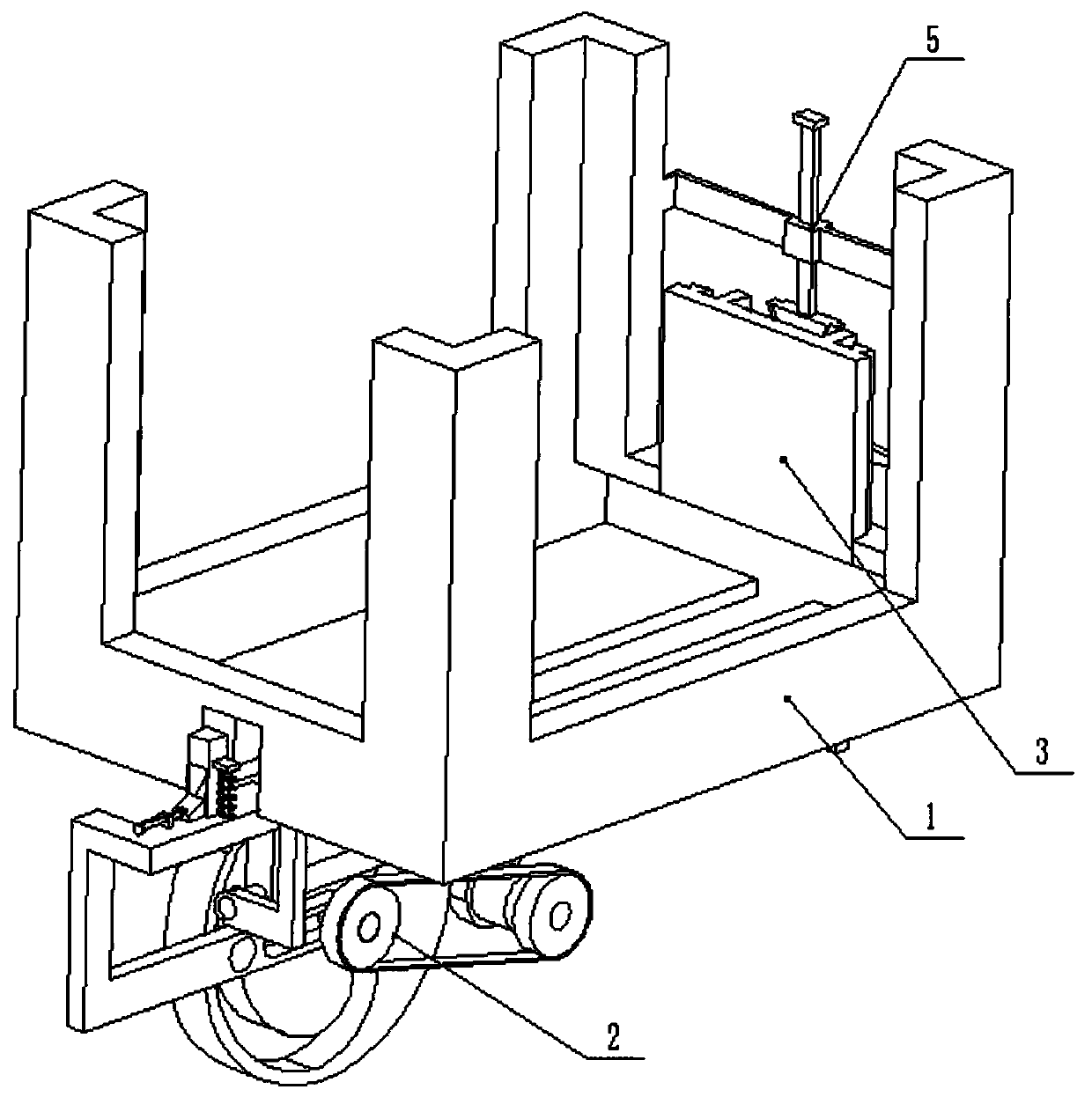

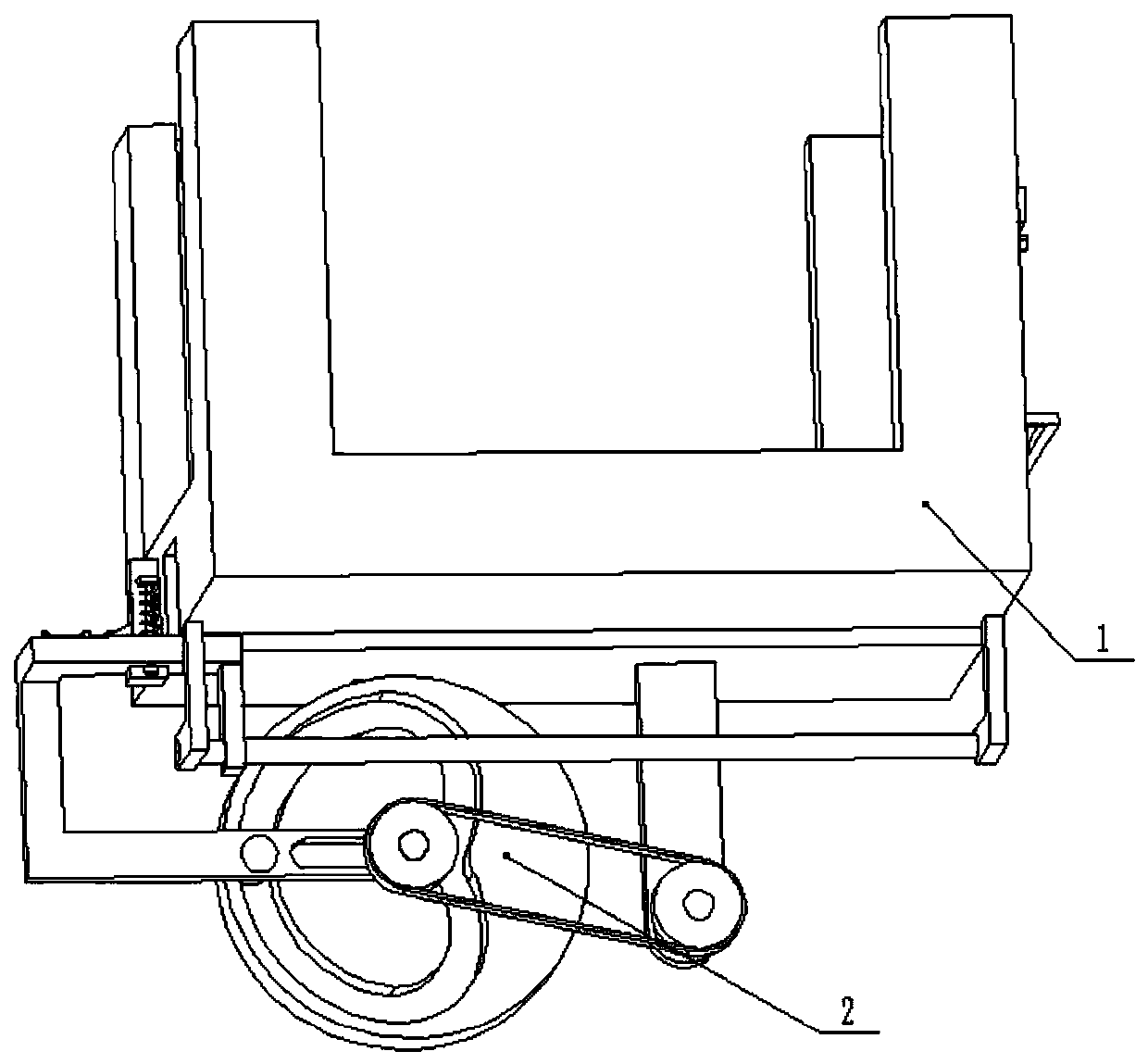

[0032] Combine below Figure 1-14 Describe this embodiment, a storage and conveying device for a new type of wood-plastic board, including a board placement frame 1 and a reciprocating push slide plate 2, the board placement rack 1 includes a board placement seat 1-1, a right-angle board 1-2, a through groove 1-3, shifting plate chute 1-4, plate outlet chute 1-5, baffle plate chute 1-6 and trapezoidal groove 1-7; the four corners of the upper end of the plate placement seat 1-1 are all fixedly connected with Right-angle plate 1-2, one end of the plate placement seat 1-1 is provided with a passing groove 1-3, the other end of the plate placement seat 1-1 is provided with a plate output groove 1-5 and a baffle chute 1-6, and the plate is placed The bottom surface of the seat 1-1 is provided with a dial chute 1-4, which is connected through the groove 1-3, the dial chute 1-4, the outlet groove 1-5 and the baffle chute 1-6, and the baffle Two trapezoidal grooves 1-7 are arranged ...

specific Embodiment approach 2

[0035] Combine below Figure 1-10 To illustrate this embodiment, the storage and conveying device for wood-plastic panels further includes a height adjustment plate 3, and the height adjustment plate 3 is provided with a trapezoidal slide rail 3-1, a socket seat 3-2 and a positioning socket. Holes 3-3; two trapezoidal slide rails 3-1 are fixedly connected on the height adjustment plate 3, and two jack seats 3-2 are fixedly connected on the height adjustment plate 3, and both jack seats 3-2 are provided with There are a plurality of positioning jacks 3-3; the height adjustment plate 3 is slidably connected in the baffle chute 1-6, and the two trapezoidal slide rails 3-1 are slidably connected in the two trapezoidal grooves 1-7 respectively. When the height adjusting plate 3 is in use, it is suitable for outputting plates of different heights by changing the length at which the lower end of the height adjusting plate 3 is inserted into the plate output groove 1-5.

specific Embodiment approach 3

[0037] Combine below Figure 1-10 To illustrate this embodiment, the storage and conveying device for wood-plastic boards also includes a height control block 4, and the height control block 4 includes a door-shaped seat 4-1, a trapezoidal slide bar 4-2, a card Block 4-3 and tension spring 4-4; the two ends of door-shaped seat 4-1 are respectively fixedly connected on two right-angle plates 1-2, and trapezoidal slide bar 4-2 is fixedly connected on door-shaped seat 4- In the middle of 1, two blocks 4-3 are slidably connected to both ends of the trapezoidal slide bar 4-2, and the tension spring 4-4 is fixedly connected between the two blocks 4-3. When the height control block 4 is in use, when the two blocks 4-3 slide toward the outer ends at the same time, the outer ends of the two blocks 4-3 are snapped into the upper phases of the two socket seats 3-2. In the corresponding positioning socket 3-3, the position of the height adjustment plate 3 is fixed, and the tension spri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com