A method for refining aromatics using a microporous mesoporous core-shell structure composite molecular sieve

A composite molecular sieve and core-shell structure technology, applied in the field of aromatics refining, can solve the problems of catalyst pore blockage, catalyst deactivation, etc., and achieve the effects of catalytic performance recovery, good regeneration performance, and high reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

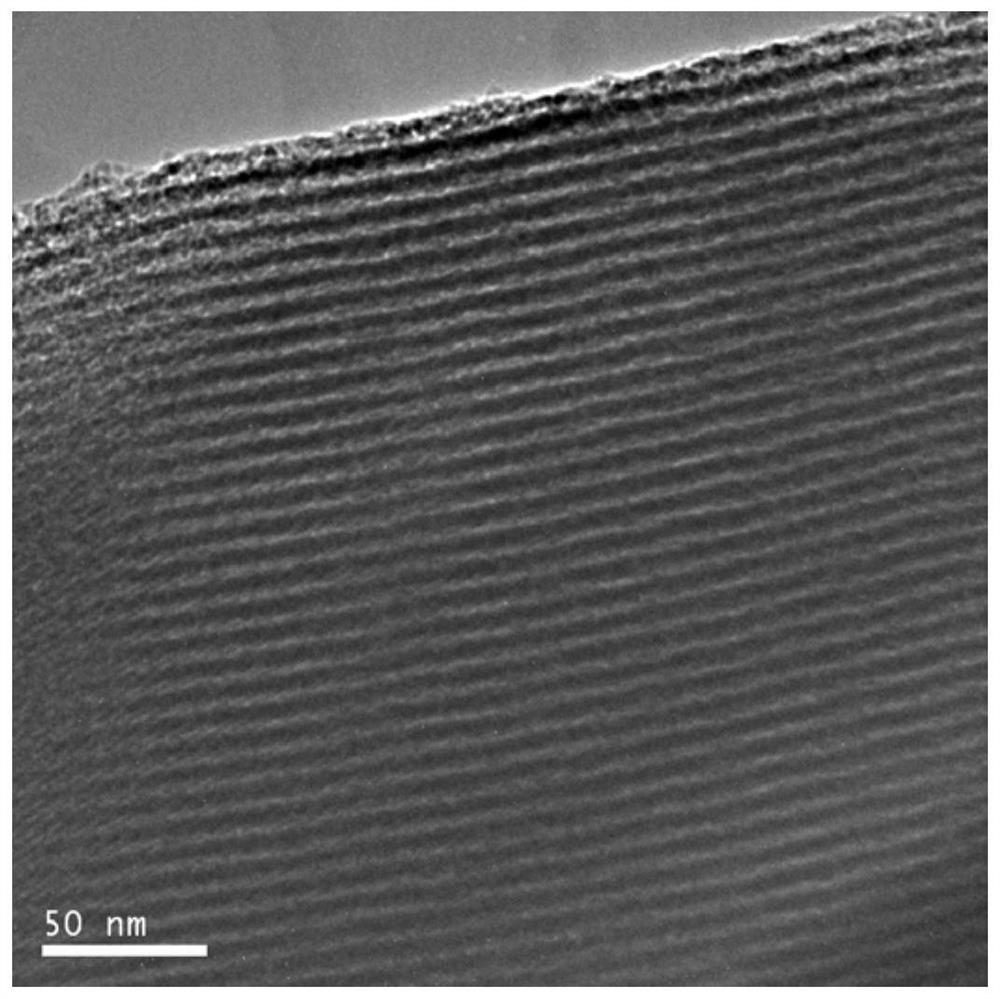

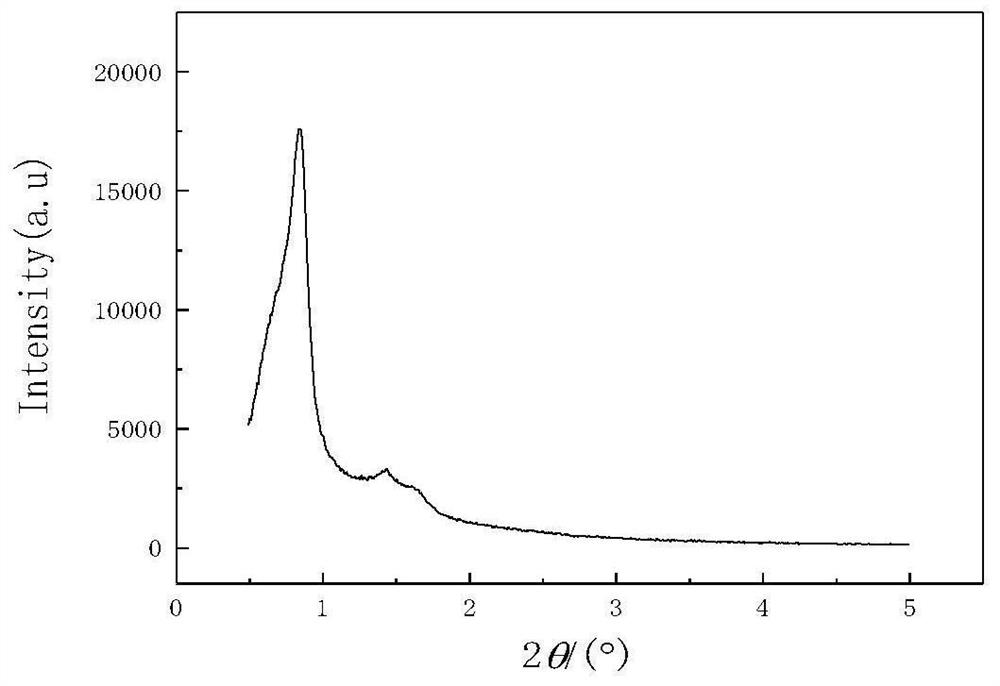

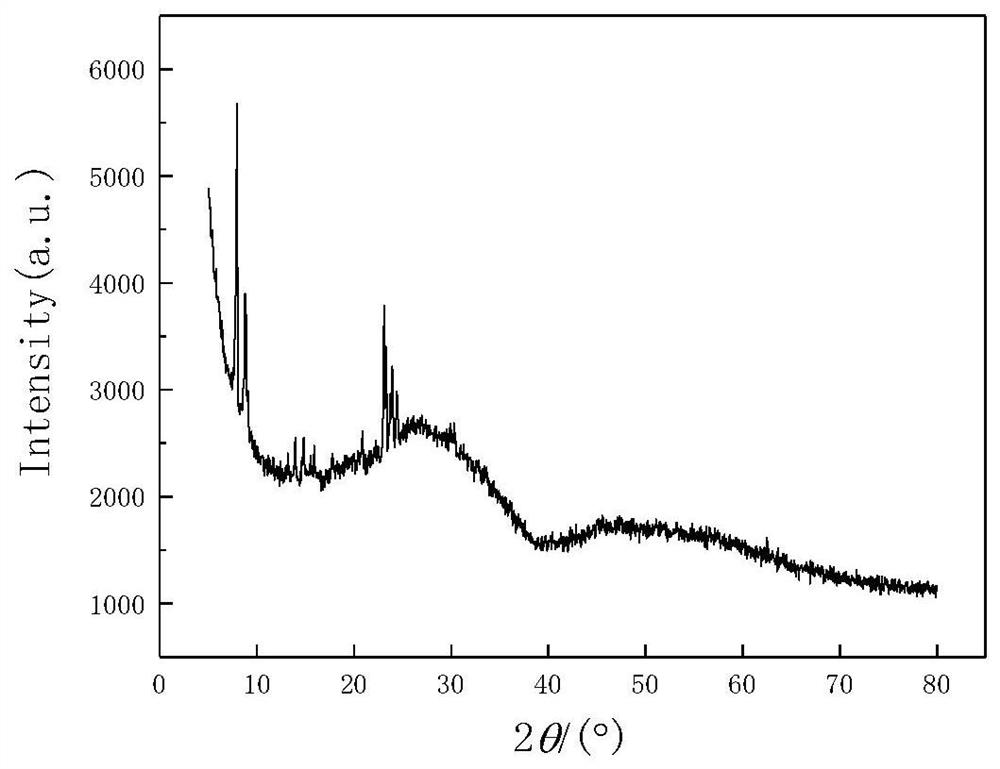

[0040] Example 1: Preparation of ZrPO / HZSM-5 core-shell structure composite molecular sieve catalyst

[0041] (1) Synthesis of ZrPO / HZSM-5 core-shell composite molecular sieve powder with HZSM-5 microporous molecular sieve as the core and ZrPO mesoporous molecular sieve as the shell

[0042] According to the solid-liquid mass ratio of 1:10, 2.0 g of HZSM-5 microporous molecular sieve powder with inner core and 1.0% mass concentration of triblock copolymer FI27 (EO 106 PO 70 EO 106 ) ethanol solution was stirred and mixed, and was continuously stirred at 30° C. for 10 h to obtain mixture A. According to the molar ratio of P to Zr n P / n Zr =0.8, the molar ratio of F127 to P+Zr n F127 / (n P +n Zr )=0.014 ratio, dissolve 57.6g (4.57mmol) F127 in 600mL absolute ethanol, stir at 40°C for 30min to obtain F127 ethanol solution; dissolve 58.0g (180.0mmol) zirconium oxychloride in 300mL absolute ethanol , and stirred at 40°C for 30min to obtain zirconium oxychloride ethanol sol...

Embodiment 2

[0045] Example 2: Al 0.25 Zr 0.75Preparation of PO / Hβ Core-Shell Composite Molecular Sieve Catalyst

[0046] (1) Al 0.25 Zr 0.75 Synthesis of PO / Hβ Core-Shell Composite Molecular Sieve

[0047] According to the solid-liquid mass ratio of 1:30, 5.0 g of the inner core microporous Hβ molecular sieve powder was stirred and mixed with the FI27 ethanol solution with a mass concentration of 3.0%. According to the molar ratio of P to total metal n P / (n Zr +n Al )=0.75, the mole ratio n of F127 and P+Zr+Al F127 / (n P +n Zr +n Al )=0.016 ratio, dissolve 63.0g (5.0mmol) F127 in 600mL absolute ethanol, stir at 30°C for 60min to obtain F127 ethanol solution; dissolve 43.5g (135.0mmol) zirconium oxychloride in 300mL absolute ethanol , and stirred at 30°C for 60min to obtain zirconium oxychloride ethanol solution; 6.0g (45.0mmol) of anhydrous aluminum chloride was dissolved in 150mL of absolute ethanol, and stirred at 30°C for 60min to obtain aluminum chloride ethanol solution ...

Embodiment 3

[0050] Example 3: Ca 0.05 Zr 0.95 Preparation of PO / HY Core-Shell Structure Composite Molecular Sieve Catalyst

[0051] (1)Ca 0.05 Zr 0.95 Synthesis of PO / HY Core-Shell Composite Molecular Sieve

[0052] According to the solid-liquid mass ratio of 1:50, 10.0 g of the inner core microporous HY molecular sieve powder was stirred and mixed with the FI27 ethanol solution with a mass concentration of 5.0%. According to the molar ratio of P to metal n P / (n Zr +n Ca )=0.95, the molar ratio n of F127 to P+Zr+Ca F127 / (n P +n Zr +n Ca )=0.036 ratio, dissolve 126.0g (10.0mmol) F127 in 800mL absolute ethanol, stir at 40°C for 30min to obtain F127 ethanol solution; dissolve 43.5g (135.0mmol) zirconium oxychloride in 300mL absolute ethanol , stirred at 40°C for 30min to obtain an ethanolic solution of zirconium oxychloride; dissolve 0.79g (7.1mmol) of anhydrous calcium chloride with 100mL of anhydrous ethanol, and stirred at 30°C for 60min to obtain a calcium chloride ethanol s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molar mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com