Cotton toothbrush manufacturing process and cotton toothbrush

A manufacturing process, toothbrush technology, applied in the field of toothbrush manufacturing, can solve the problems of labor, time-consuming, laborious, high cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

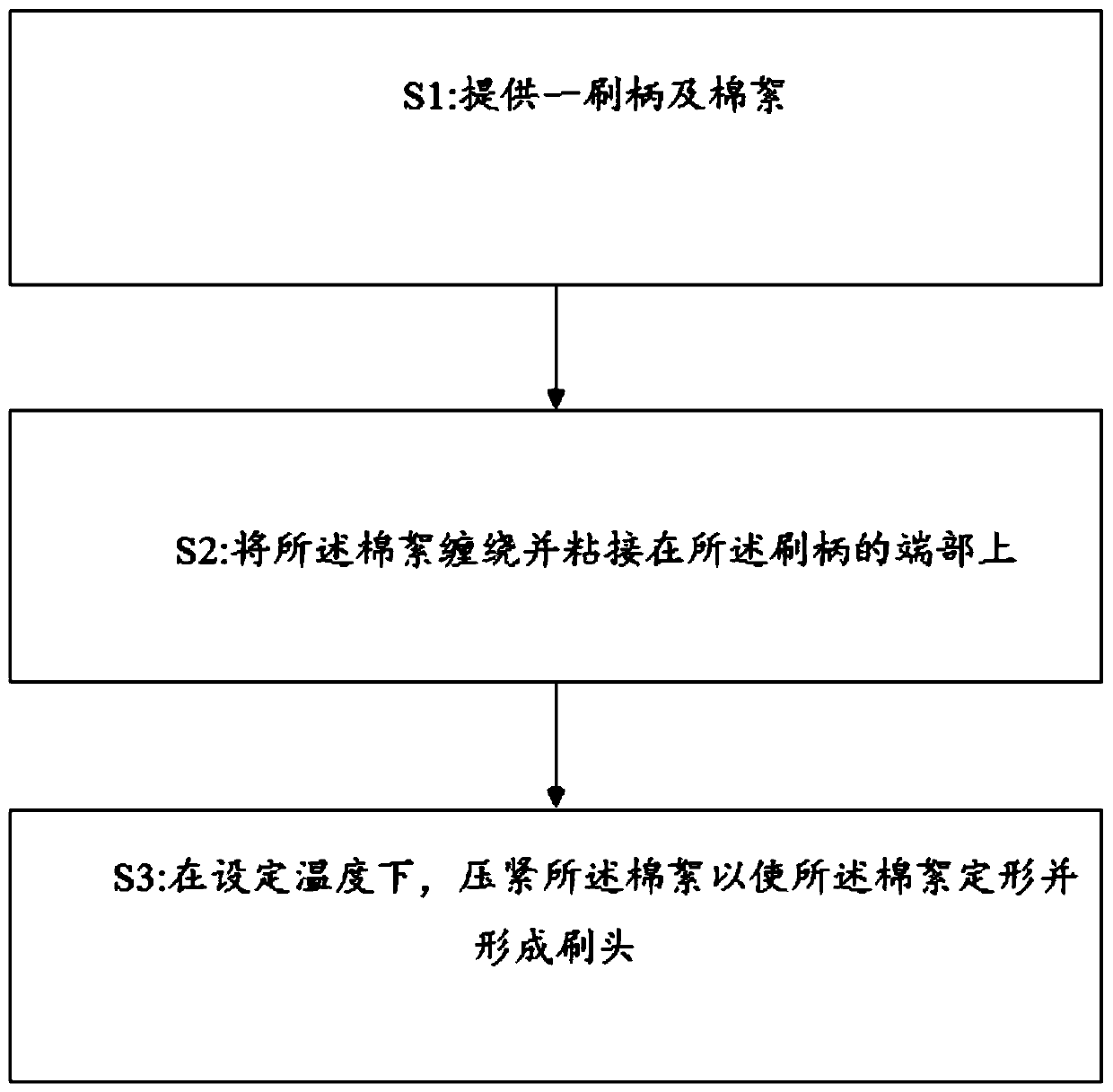

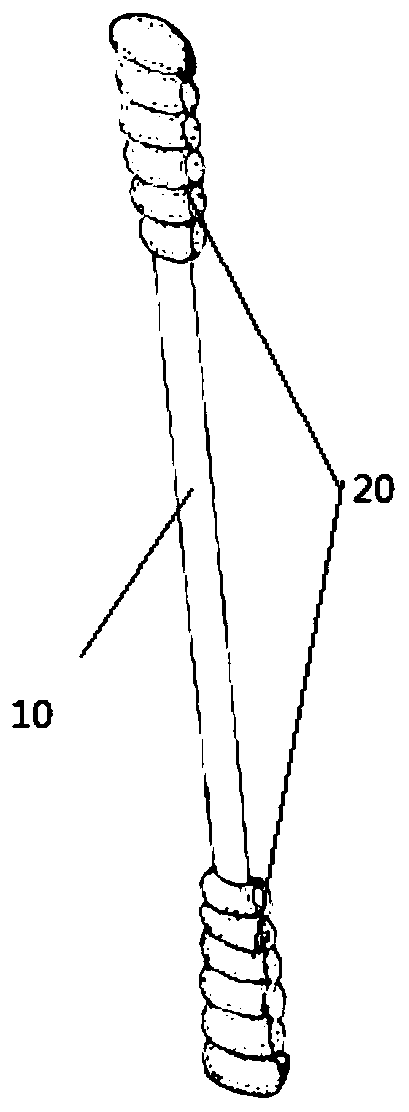

[0058] Such as figure 1 , figure 2 and image 3 As shown, the present embodiment provides a kind of cotton toothbrush manufacturing process, comprising:

[0059] S1: provide a brush handle 10 and cotton wool;

[0060] S2: Winding and pasting the cotton wool on the end of the brush handle 10;

[0061] S3: Pressing the cotton wool at a set temperature to shape the cotton wool and form the brush head 20 .

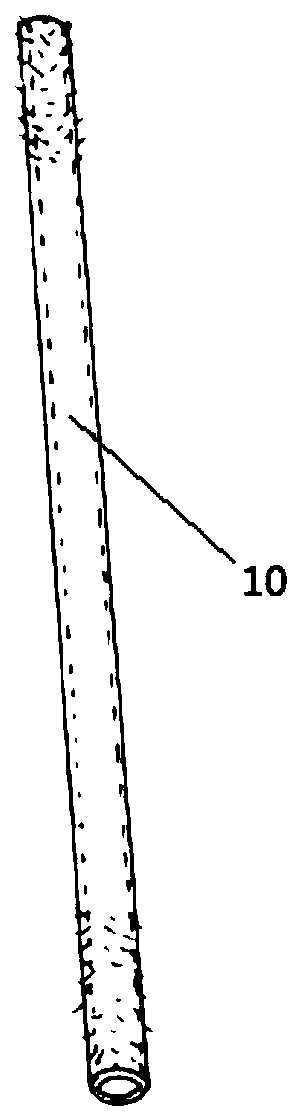

[0062] First, execute step S1: provide a brush handle 10 and cotton wool.

[0063] Specifically, the cotton toothbrush is mainly a disposable toothbrush made of cotton fiber to meet the needs of special personnel such as puerpera, infants, the elderly, and periodontitis patients. The shape of the brush handle 10 may be a cylinder, a hexahedron, or an irregular shape, which is not limited in this application. The material of the brush handle 10 may be plastic, wood or other materials, which is not limited in this application. In this embodiment, the brush handle 10 is a...

Embodiment 2

[0096] Different from Embodiment 1, in this embodiment, if Image 6 As shown, the brush handle 10 has a liquid filling hole 110 inside, the liquid filling hole penetrates the brush handle 10 along the axial direction, and the liquid filling hole 110 is filled with dentifrice. By setting the liquid filling hole 110 filled with dentifrice in the brush handle 10, and forming a negative pressure in the brush handle 10, the end of the brush handle 10 away from the brush head 20 is cut off when the tooth surface is cleaned and maintained. Open to balance the internal and external air pressure of the liquid filling hole 110, and the end provided with the brush head 20 faces down, and the dentifrice flows down to the brush head 20 due to gravity, and then soaks the cotton wool on the brush head 20 to realize the tooth surface protection. maintainance. Especially for double-ended toothbrushes, such as Image 6 As shown, one end of the brush handle 10 is a decontamination brush head 2...

Embodiment 3

[0107] Based on the toothbrush manufacturing process, this embodiment also provides a cotton toothbrush, please continue to refer to Image 6 , the cotton toothbrush includes a brush handle 10 and cotton wool, the end of the brush handle 10 is formed by winding the cotton wool to form a brush head 20, the brush handle 10 is provided with a shaft penetrating through the brush handle 10 in the axial direction The liquid filling hole 110 is filled with dentifrice, one end of the liquid filling hole 110 is closed, and the pressure inside the liquid filling hole 110 is lower than the external atmospheric pressure.

[0108] In this embodiment, the number of the brush head 20 is one, which is arranged at one end of the brush handle 10 . The brush head 10 is in the shape of an ellipsoid, thick in the middle and thin at the edges, and has two symmetrically arranged brush surfaces, and the brush surfaces are used to contact the tooth surface to clean the tooth surface.

[0109] Optiona...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com