Beer aroma type breakable bead essence and preparation method thereof and breakable bead

A technology for bead essence and beer, which is applied to beer-flavored beer-flavored bead flavor and its application in cigarettes, can solve the problems of poor coordination of smoke, lack of targeted design of flavor and fragrance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

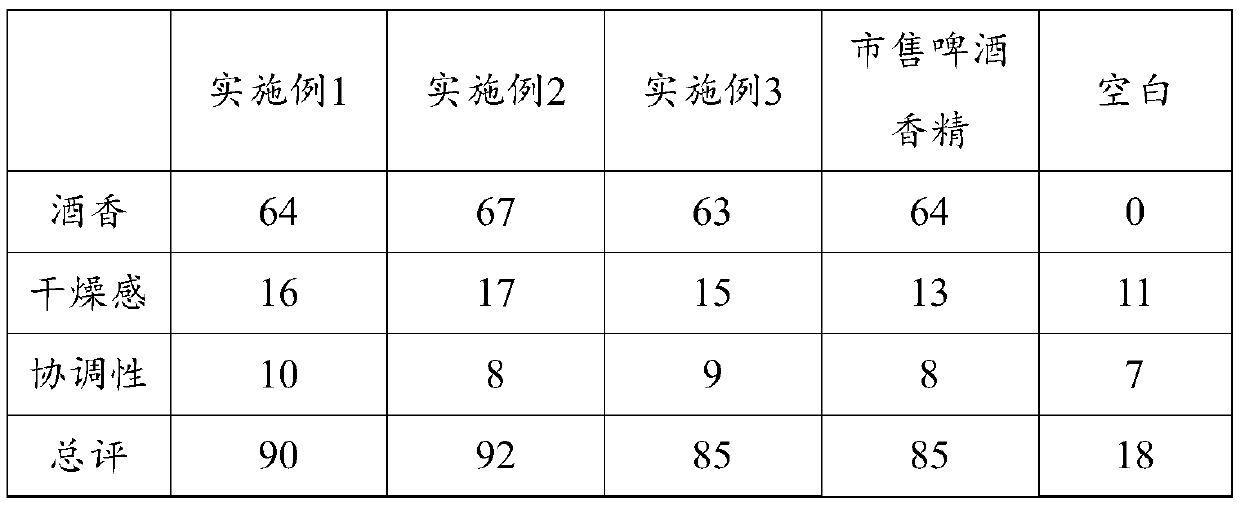

Examples

Embodiment 1

[0022] Beer-flavored pop-bead flavor, consisting of the following components by weight: 1 part of ethyl butyrate, 3 parts of beer fragrance base, 10 parts of phenylethyl alcohol, 80 parts of caprylic glyceride, 1.8 parts of acetic acid, 0.13 parts of ethyl lactate 3.8 parts of ethyl acetate, 1 part of furfuryl alcohol, 2 parts of dimethyl sulfide, 0.1 part of isobutanol, 0.11 parts of propionic acid;

[0023] Wherein, the beer aroma base is composed of the following components by weight: 0.8 parts of ethyl octanoate, 0.6 parts of phenylethyl acetate, 0.14 parts of n-butanol, 2.3 parts of ethyl maltol, 0.8 parts of methyl acetyl alcohol Parts, 0.5 parts of furfural, 91 parts of glyceryl caprylate.

[0024] Its preparation method comprises the following steps:

[0025] 1. Weighing raw materials; 2. Mixing: 3. Stirring; 4. Standing and maturing at room temperature (20-30°C) for 15 days, then it can be prepared.

Embodiment 2

[0027] Beer-flavored pop-bead flavor, consisting of the following components by weight: 2 parts of ethyl butyrate, 4 parts of beer fragrance base, 4 parts of phenylethyl alcohol, 81 parts of caprylic glyceride, 0.3 part of acetic acid, 0.15 parts of ethyl lactate 2.8 parts of ethyl acetate, 0.55 parts of furfuryl alcohol, 2 parts of dimethyl sulfide, 0.2 parts of isobutanol, and 0.13 parts of propionic acid;

[0028] Wherein, the beer aroma base is composed of the following components in parts by weight: 0.5 parts of ethyl octanoate, 0.6 parts of phenylethyl acetate, 0.14 parts of n-butanol, 2.3 parts of ethyl maltol, 0.8 parts of methyl acetyl alcohol Parts, 0.7 parts of furfural, 92 parts of caprylic acid glyceride.

[0029] Its preparation method comprises the following steps:

[0030] 1. Weighing raw materials; 2. Mixing: 3. Stirring; 4. Standing and maturing at room temperature (20-30°C) for 16 days, then it can be prepared.

Embodiment 3

[0032] Beer-flavored pop-bead flavor, consisting of the following components in parts by weight: 1.3 parts of ethyl butyrate, 2 parts of beer fragrance base, 8 parts of phenylethyl alcohol, 81 parts of caprylic glyceride, 1.8 parts of acetic acid, 0.18 parts of ethyl lactate 2.0 parts of ethyl acetate, 0.05 parts of furfuryl alcohol, 1 part of dimethyl sulfide, 0.3 parts of isobutanol, and 0.11 parts of propionic acid;

[0033] Wherein, the beer aroma base is composed of the following components by weight: 0.4 parts of ethyl octanoate, 0.6 parts of phenylethyl acetate, 0.1 parts of n-butanol, 1.0 parts of ethyl maltol, 0.5 parts of methyl acetyl alcohol parts, 0.9 parts of furfural, and 90 parts of glyceryl caprylate.

[0034] Its preparation method comprises the following steps:

[0035] 1. Weighing raw materials; 2. Mixing: 3. Stirring; 4. Standing and maturing at room temperature (20-30°C) for 16 days, then it can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com