Method for producing high-quality mulberry wine by fermentation

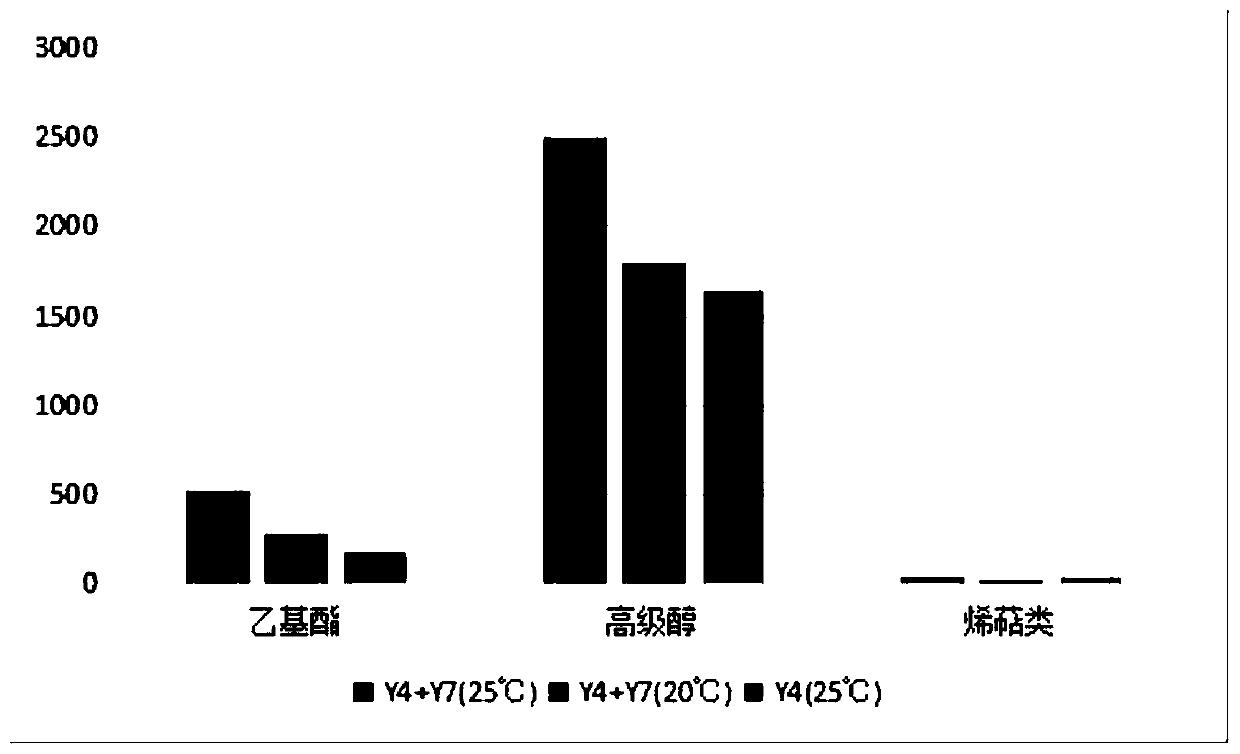

A mulberry wine, high-quality technology, applied in the field of bioengineering, can solve the problems of inability to complete alcoholic fermentation, low ethanol tolerance, etc., and achieve the effects of soft and mellow taste, improved ester aroma, and rich fruit aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

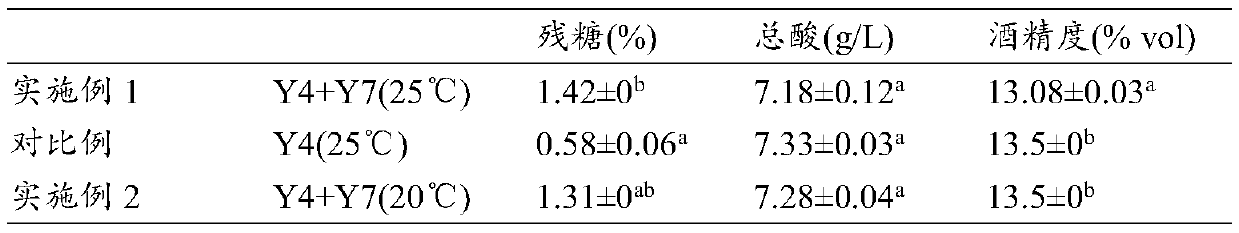

Embodiment 1

[0021] 1.2kg of fresh mulberry raw materials are selected, washed, and crushed, and 0.15g NaHSO is added immediately after crushing 3 , add 0.09g pectinase, let it stand for 8h under the condition of constant temperature of 25 ℃; add 0.23g (NH 4 ) 2 HPO 3 , add 120g of sucrose. Simultaneously inoculate an equal amount of activated Saccharomyces pumilii Y4 and Torula dell's yeast Y7, so that the initial cell concentration of the two yeasts is 10 6 CFU / mL (activation method: pick an appropriate amount of bacteria from the slant of the wort test tube, and expand it step by step in the wort liquid medium twice until the bacteria content reaches 10 7 ), 105 g of sucrose was added after 6 days of fermentation at a constant temperature of 20° C., continued to ferment for 4 days, and filtered immediately to obtain mulberry wine.

Embodiment 2

[0023] 1.2kg of fresh mulberry raw materials are selected, washed, and crushed, and 0.18g NaHSO is added immediately after crushing 3 , add 0.105g of pectinase, and let stand at 25°C for 8h. Add 0.23g (NH 4 ) 2 HPO 3 , add 120g of sucrose. Simultaneously inoculate the same amount of activated Saccharomyces bayeri Y4 and Torula dell's yeast Y7, so that the initial cell concentration of the two yeasts is 3x10 6 CFU / mL (activation method: pick an appropriate amount of bacteria from the slant of the wort test tube, and expand it step by step in the wort liquid medium twice until the bacteria content reaches 10 7 ), 105 g of sucrose was added after 6 days of fermentation at a constant temperature of 25° C., continued to ferment for 4 days, and filtered immediately to obtain mulberry wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com