Regenerated carbon fiber reinforced PA6 material and preparation method thereof

A fiber-reinforced and recycled carbon technology, which is applied in the direction of plastic recycling and recycling technology, can solve the problems of unstable and stable feeding, limited RCF, and low stacking area density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

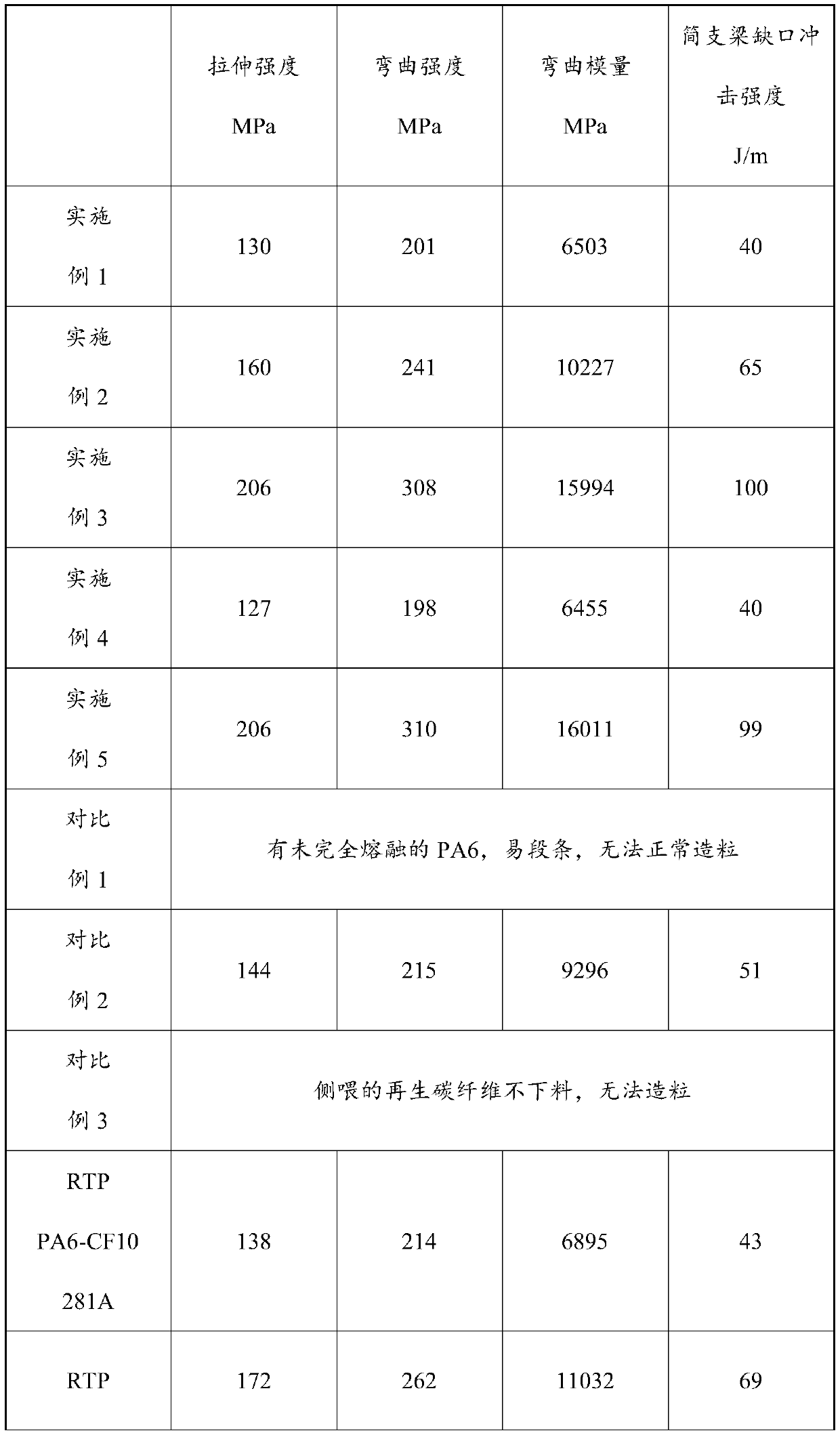

Examples

preparation example Construction

[0016] On the one hand, the present disclosure relates to a preparation method of recycled carbon fiber reinforced PA6 material, which comprises:

[0017] The first mixture, the first mixture is made of sizing agent, recycled carbon fiber, BOPA film;

[0018] A second mixture, the second mixture is made of PA6 resin, antioxidant; and

[0019] The first mixture and the second mixture are extrusion pelletized.

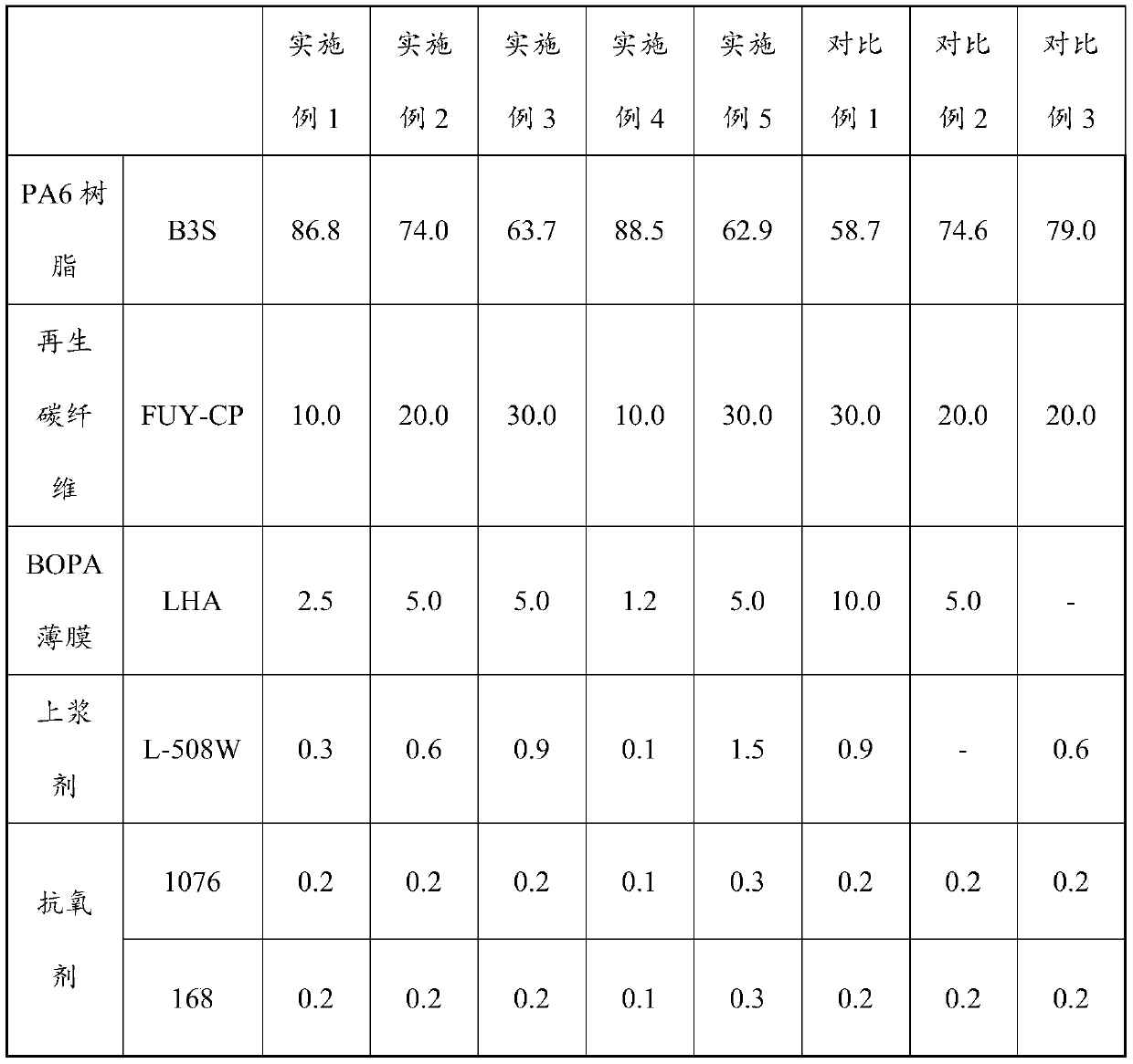

[0020] In some embodiments, the first mixture is prepared from 0.1 to 1.5 parts of sizing agent, 10.0 to 30.0 parts of recycled carbon fiber, and 1.2 to 5.0 parts of BOPA film in parts by weight.

[0021] In some embodiments, the second mixture is prepared from 62.9 to 88.5 parts of PA6 resin and 0.2 to 0.6 parts of antioxidant in parts by weight.

[0022] In certain embodiments, the sizing agent is selected from waterborne epoxy resins, polyurethane resins, polyimides, vinyl ester resins, or mixtures thereof.

[0023] In certain embodiments, the sizing agent is selec...

Embodiment 1

[0073] Put 0.3% by weight (0.03 times the weight of FUY-CP) of L-508W in the container, add 9.7% by weight of deionized water, and stir evenly; put 10.0% by weight of FUY-CP into the container to fully saturate the absorption solution , and then dry in an oven at 100 ° C for 3-4 hours to dry the water. Use 2.5% by weight (0.25 times the weight of FUY-CP) of LHA with a width of 18 cm to wrap the sized regenerated carbon fiber layered into a "hamburger" shape, press it into a plate shape at 245 ° C with a flat vulcanizer, and then crush it The machine crushes it into crushed material with a particle size of 8-20mm. Put 86.8% by weight of B3S, 0.2% by weight of 1076, and 0.2% by weight of 168 in the mixing pot at a controlled speed of 850 rpm and stirring time for 4 minutes. After mixing the materials, feed them into the extruder from the main feed, and feed the crushed materials from the side Add to extruder, extrude and granulate. The temperature of each section of the twin-s...

Embodiment 2

[0075] The amount of each raw material is shown in Table 1, the weight of deionized water is the weight of FUY-CP minus the weight of L-508W, and the recycled carbon fiber reinforced PA6 material is prepared according to the method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com