Tetracycline hollow double-imprinted layer magnetic nanospheres as well as preparation method and application thereof

A magnetic nanosphere, tetracycline technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve the problems of increasing bacterial resistance, time-consuming separation process, complex efficiency, etc. The effect of surface functionalization, uniform particle size, and increased mass transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing tetracycline hollow double-imprinted layer magnetic nanospheres includes the following steps:

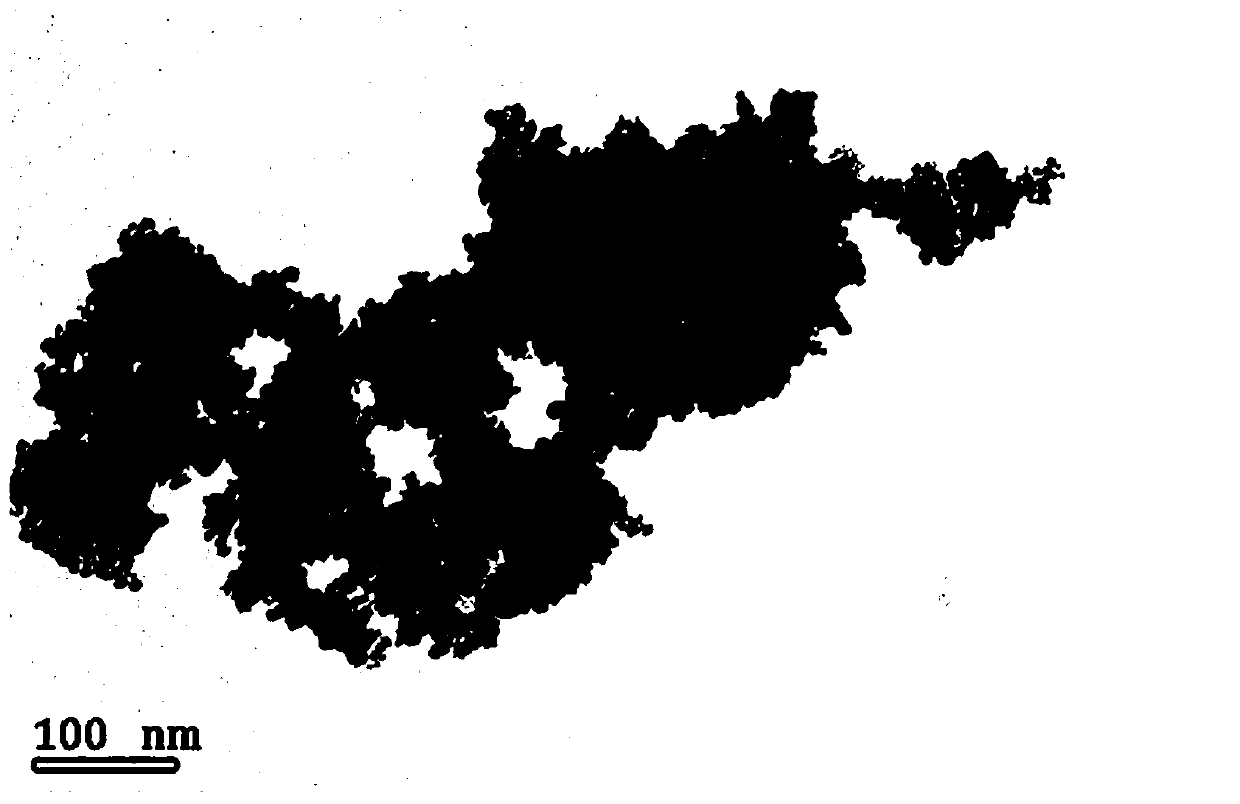

[0038] Step 1. Put 1.0g ferric chloride hexahydrate, 20mL secondary water, 5mL ammonia water, 1.05g ferric chloride tetrahydrate in a three-necked flask, and react at 25°C for 10 minutes. After the reaction, the reaction product is ultra-pure Wash with water and vacuum dry at 20°C and 0.02MPa for 3h. Such as figure 1 As shown, the particle size of the prepared small-diameter magnetic nanospheres is about 5 nm.

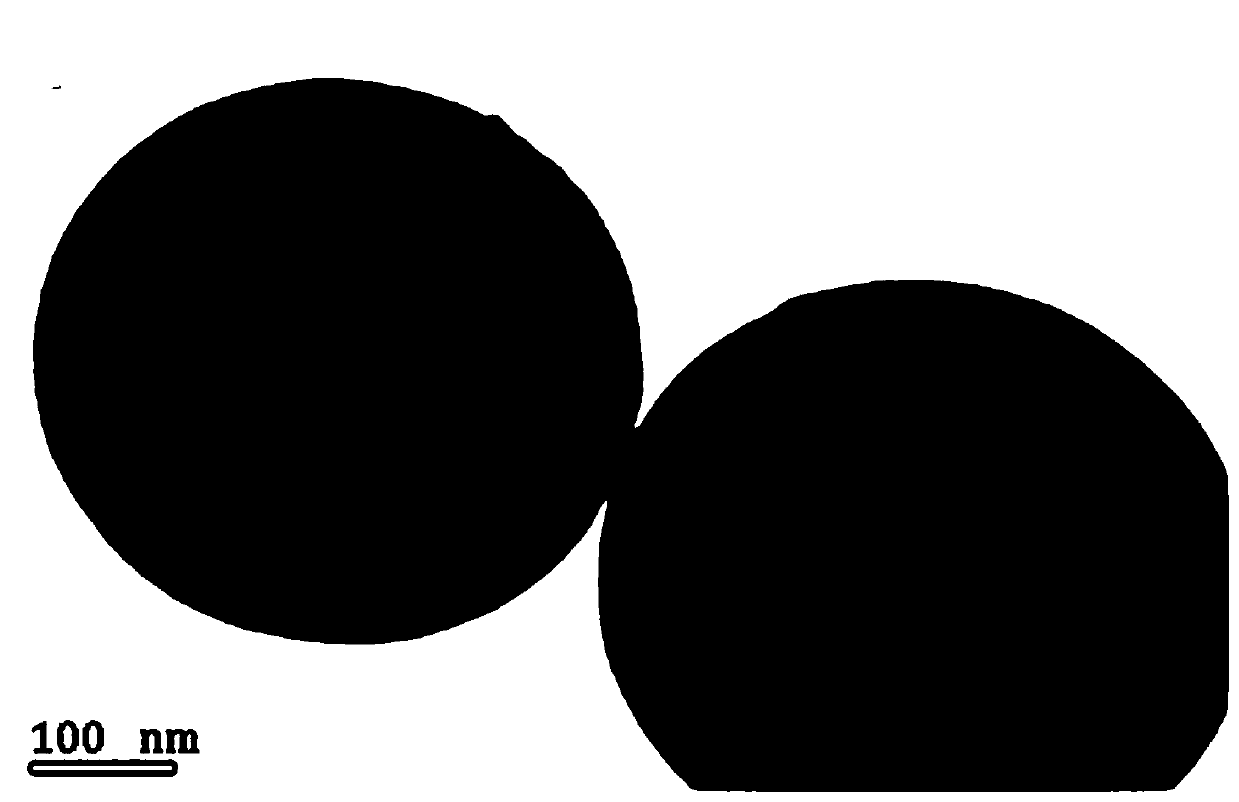

[0039] Step 2. Put 5mL concentrated ammonia water, 10mL ethanol and 10mL distilled water in a three-necked flask, stir mechanically for 5min at a rotation speed of 1000r / min, add 1.5mL TEOS and 15mL ethanol to the above solution at a rotation speed of 100r / min Under the condition of mechanical stirring for 1h, finally centrifuged to obtain silica nanospheres. Such as figure 2 As shown, the particle size of the prepared silica nanospheres is about ...

Embodiment 2

[0052] A method for preparing tetracycline hollow double-imprinted layer magnetic nanospheres includes the following steps:

[0053] Step 1. Put 2.0 g of ferric chloride hexahydrate, 30 mL of secondary water, 8 mL of ammonia, and 2.72 g of ferric chloride tetrahydrate in a three-necked flask, and react at 40°C for 50 minutes. After the reaction, the reaction product is ultra-pure Washing with water, vacuum drying at 30°C and 0.04 MPa for 4 hours, to prepare small particle size magnetic nanospheres.

[0054] Step 2. Place 10mL concentrated ammonia water, 21mL ethanol and 22mL distilled water in a three-necked flask, stir mechanically for 10min at a rotation speed of 1200r / min, add 3mL TEOS and 25mL ethanol to the above solution at a rotation speed of 150r / min Under mechanical stirring for 3 hours, and finally centrifuge to obtain silica nanospheres.

[0055] Step 3. Put 15mg magnetic nanospheres, 15mg tetracycline, 40mg silicon spheres, 60mg dopamine and 10mL Tris-HCl in the reaction...

Embodiment 3

[0067] A method for preparing tetracycline hollow double-imprinted layer magnetic nanospheres includes the following steps:

[0068] Step 1. Put 4.5g of ferric chloride hexahydrate, 40mL of secondary water, 12mL of ammonia water, and 3.5g of ferric chloride of tetrahydrate in a three-necked flask, and react at 55°C for 100 minutes. After the reaction is over, the reaction product is ultra-pure Wash with water and vacuum dry at 40°C and 0.05MPa for 5h. Prepared small particle size magnetic nanospheres.

[0069] Step 2. Put 15mL concentrated ammonia water, 30mL ethanol and 35mL distilled water in a three-necked flask, stir mechanically for 15min at a rotation speed of 1500r / min, add 5mL TEOS and 35mL ethanol to the above solution at a rotation speed of 200r / min Under mechanical stirring for 5 hours, and finally centrifuged to obtain silica nanospheres.

[0070] Step 3. Place 20mg magnetic nanospheres, 18mg tetracycline, 70mg silicon spheres, 78mg dopamine and 15mL Tris-HCl in the rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com