High-power tile type phased-array antenna

A phased array antenna and tile-type technology, which is applied in the field of communication, can solve the problems of chip heating, inability to apply high-power applications, poor chip heat dissipation, etc., to increase heat dissipation, increase heat dissipation effect, and meet heat dissipation requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

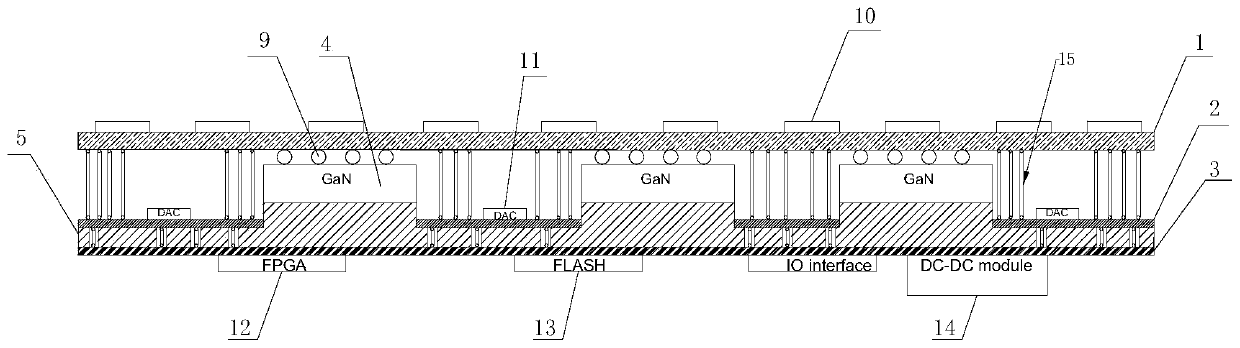

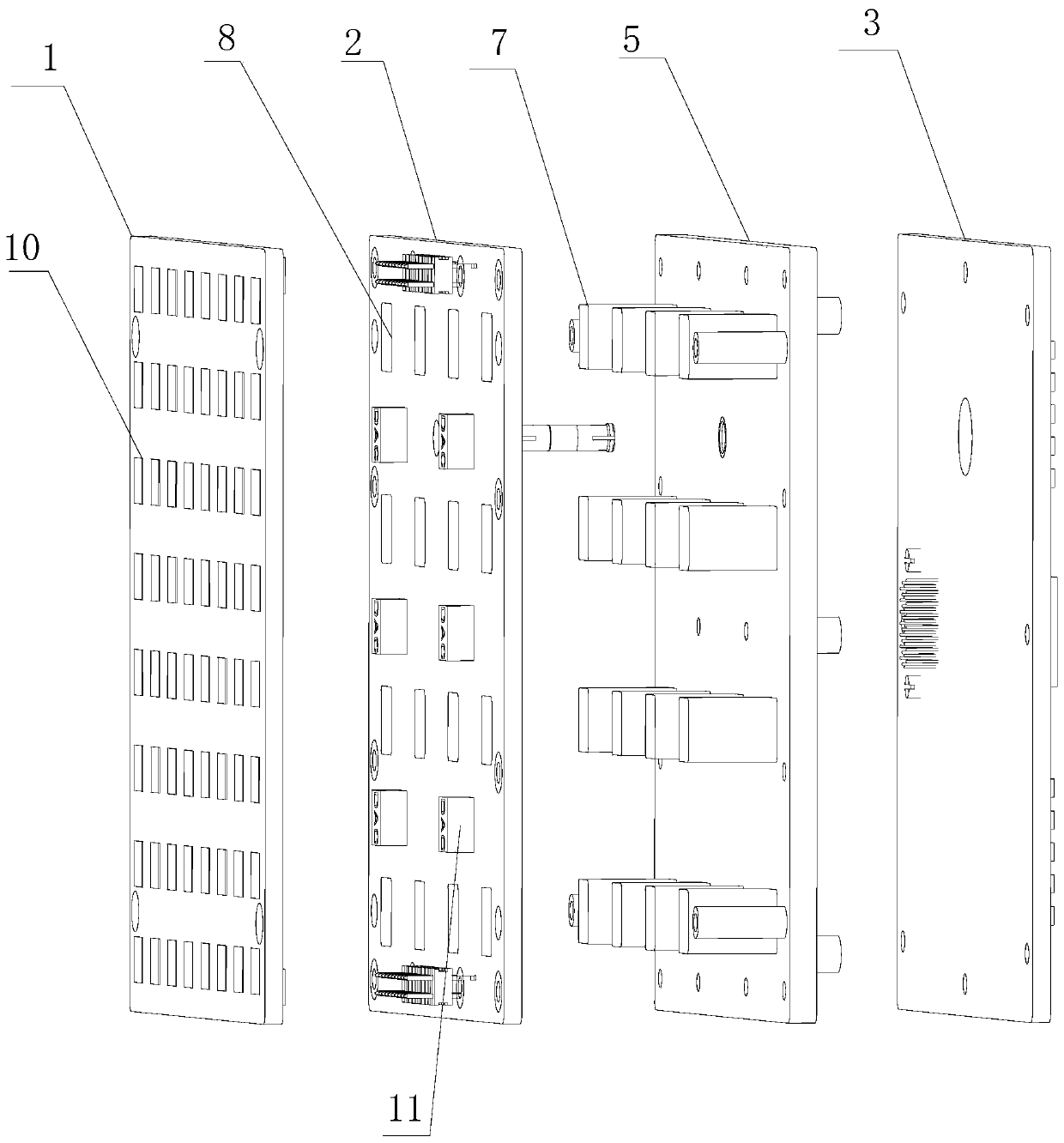

[0046] Such as Figure 1-8 As shown, the high-power tile-type phased array antenna provided in this embodiment includes a first printed circuit board layer 1 , a second printed circuit board layer 2 and a third printed circuit board layer 3 arranged in sequence.

[0047] The first printed circuit board layer 1 is used for transmitting radio frequency signals and implementing a 64-unit power division network.

[0048] The second printed circuit board layer 2 is electrically connected to the first printed circuit board layer 1 for phase shifting and attenuation of control signals.

[0049] The third printed circuit board layer 3 is electrically connected to the second printed circuit board layer 2 for power supply and signal input control.

[0050] Several chips 4 for signal output are arranged on the first printed circuit board layer 1 .

[0051]A heat dissipation cold plate 5 is also provided between the second printed circuit board layer 2 and the third printed circuit boar...

Embodiment 2

[0063] Such as Figure 1-8 As shown, this embodiment is a specific implementation of the high-power tile-type phased array antenna described in Embodiment 1.

[0064] The following is a detailed description of the structure of the phased array antenna:

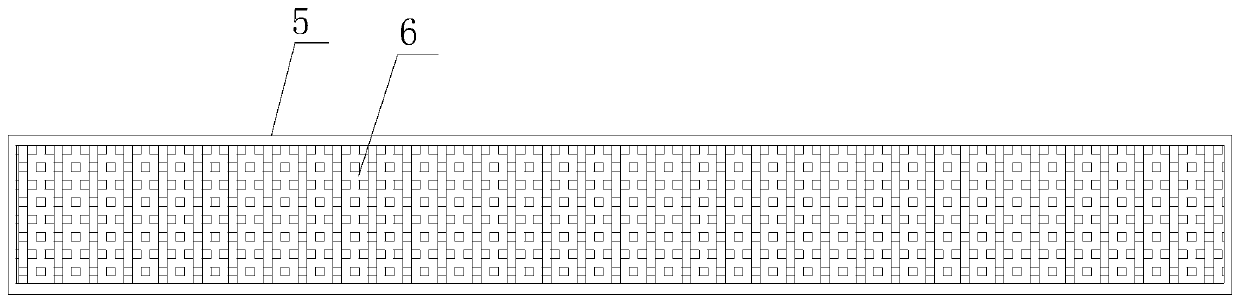

[0065] Such as figure 1 , figure 2 and image 3 As shown, the specific structure of the heat dissipation cold plate is described below:

[0066] Optimally, the heat dissipation cold plate 5 is a hollow plate, wherein a capillary heat dissipation channel 6 is provided in the inner cavity of the heat dissipation cold plate 5 , and a heat dissipation liquid is stored in the capillary heat dissipation channel 6 .

[0067] The surface of the heat dissipation cold plate 5 facing the second printed circuit board layer 2 is provided with a number of heat dissipation bosses 7 equal in number to the chips 4 .

[0068] Each heat dissipation boss 7 is used as a heat absorbing end of the heat dissipation cold plate 5 , and contacts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com