Aircraft wire harness automatic design method

A design method and aircraft technology, applied in design optimization/simulation, geometric CAD, etc., can solve problems such as limiting the improvement of design efficiency and quality, disconnection between 2D design and 3D design and simulation levels, and uneven overall levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

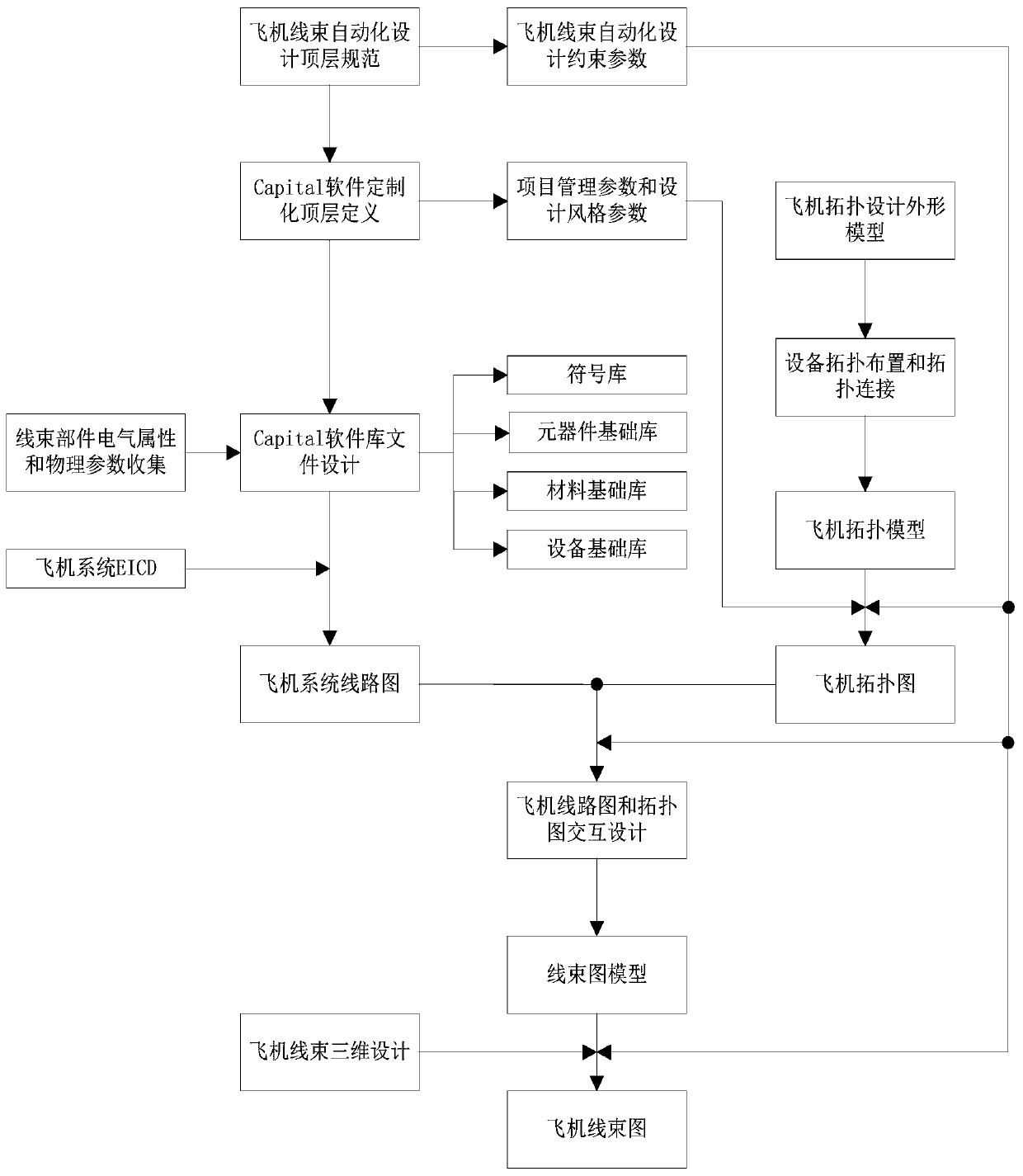

[0029] The present invention proposes a kind of automatic design method of aircraft wiring harness based on Capital software, see figure 1 , characterized in that: establish top-level specifications for aircraft wiring harness design, define design criteria and constraint principles, and form aircraft wiring harness automation design constraint parameters; combine aircraft wiring harness automation design constraint parameters, customize the top-level definition of general Capital software, and set aircraft wiring harness automation design Project management parameters and design style parameters; using the electrical properties and physical parameter information of the components involved in the existing aircraft wiring harness design, create the aircraft wiring harness Capital library file, and set the graphic symbols, component information, equipment information, Material information, forming the aircraft symbol library, component base library, equipment base library, and ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com