Near-field direct-writing technology-based micronano resistor strain gauge fabrication method and strain gauge

A technology of resistance strain gauge and manufacturing method, applied in the field of strain gauge, can solve the problems of cumbersome process and difficulty in customizing the strain gauge, and achieve the effects of simple process, low cost and easy filament formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

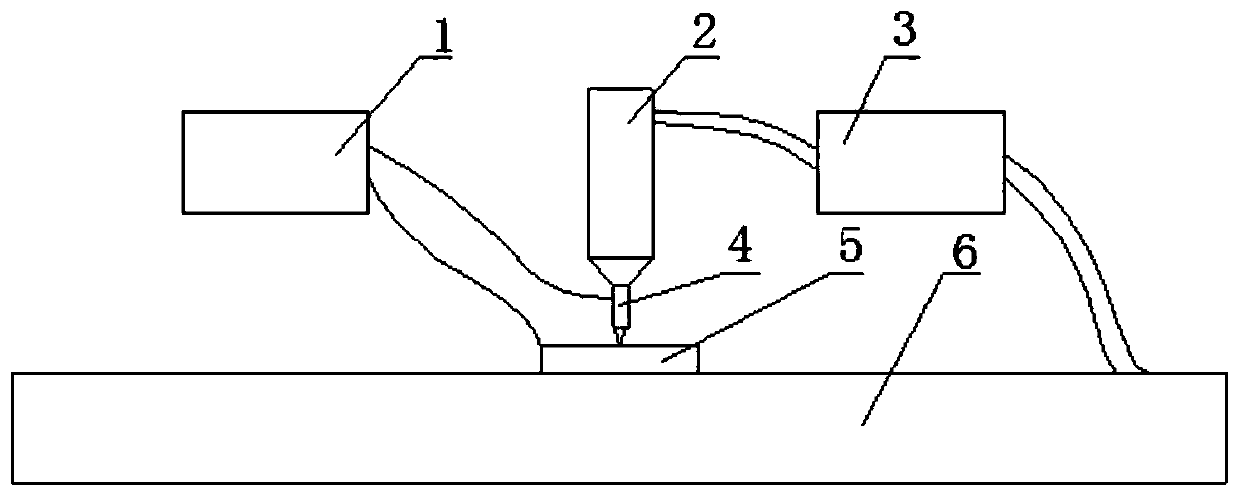

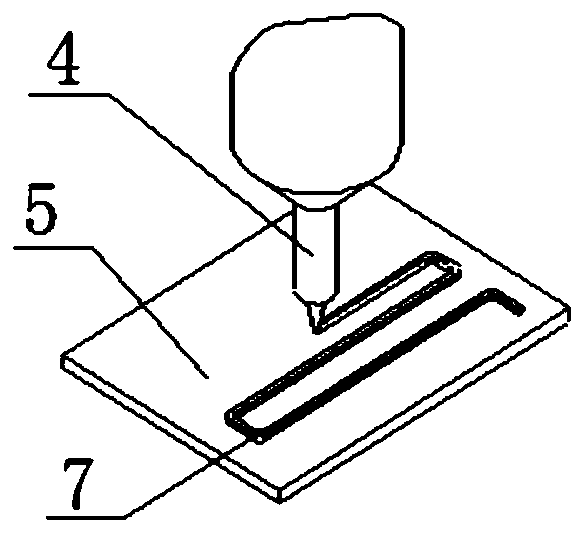

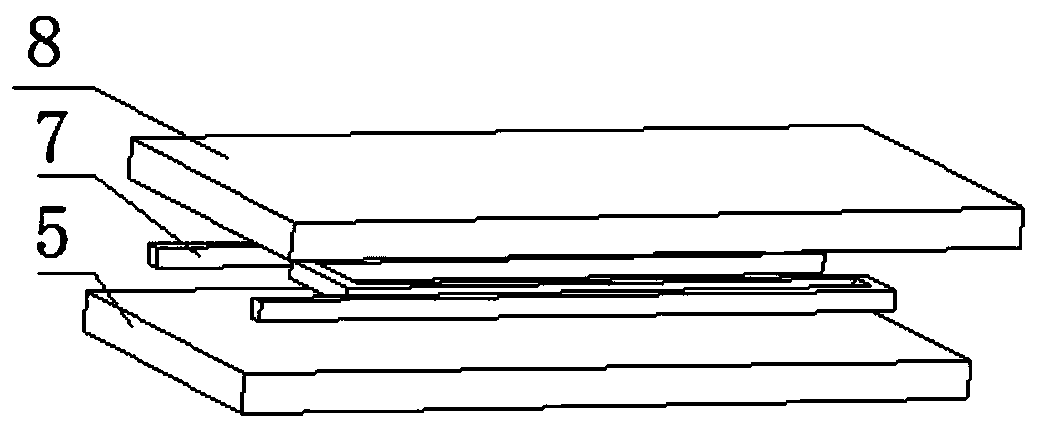

[0051] The manufacturing method and process of the strain gauges used in this embodiment are as follows:

[0052] S01: The ambient temperature and humidity are 30°C and 40%, respectively. Place an epoxy resin film with a thickness of 15um and a length and width of 10mmx5mm on the mobile platform of the near-field direct writing device. The epoxy film is glued on both sides posted on the mobile platform;

[0053] S02: Input the shape of the strain gauge sensitive grid through the input terminal of the near-field direct writing device, and the system automatically generates the control code required for the mobile platform;

[0054] S03: Put the prepared nano-silver paste into the syringe, and turn on the high-voltage power supply. The -15kv voltage is connected to the metal needle connected to the syringe. The base of the strain gauge is grounded. The distance between the metal needle and the base of the strain gauge is 8mm. The concentration of the silver paste is 10%, the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com