Shutter-type vacuum furnace observation window

A technology of observation window and vacuum furnace, which is applied in the field of flicker-free observation window structure and its protection, which can solve the problems of difficult maintenance and repair operations, increased costs, and large volume of observation windows, so as to reduce observation fatigue and prolong use The effect of long life and large aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

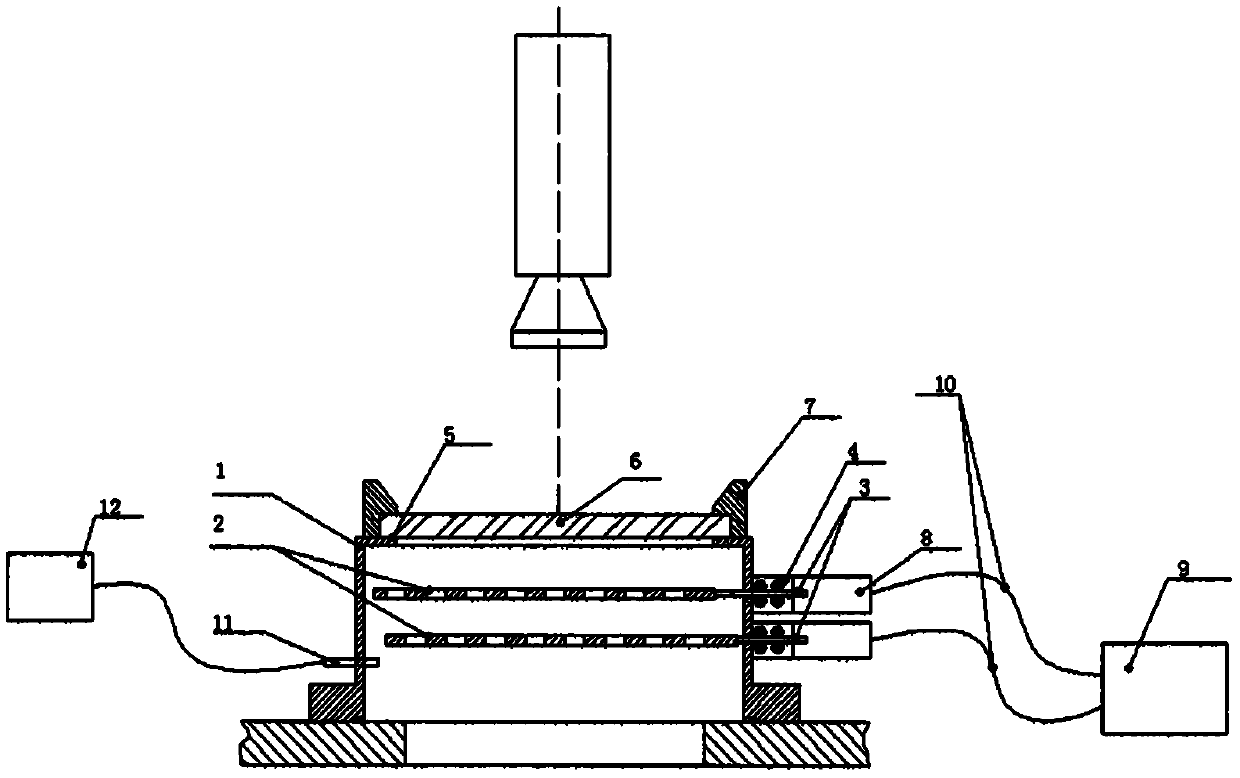

[0032] As shown in the figure, a shutter-type vacuum furnace observation window includes an observation window cavity 1 that can be installed to the observation port of the vacuum furnace, and a shutter-type blade 2 placed in the observation window cavity, which is connected to each blade and connected to an external drive system The driving link mechanism 3, the driving rod dynamic sealing mechanism 4 to ensure vacuum, the vacuum sealing ring 5 for the observation window glass sealing, the observation window glass lens 6, the observation window cover 7 that presses the observation window glass, and is placed on the observation window Outside the cavity, the drive rod actuator 8 of the drive mechanism, the control and adjustment unit 9 of the actuator and the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com