Inorganic keel purline assembly external wall and assembly method

An inorganic and keel technology, applied to walls, building components, insulation, etc., can solve the problems of increased production, transportation, installation, and management costs, large prefabricated panels, and high transportation costs, and achieve convenient transportation and installation. Facilitate construction size deviation, simple and convenient management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

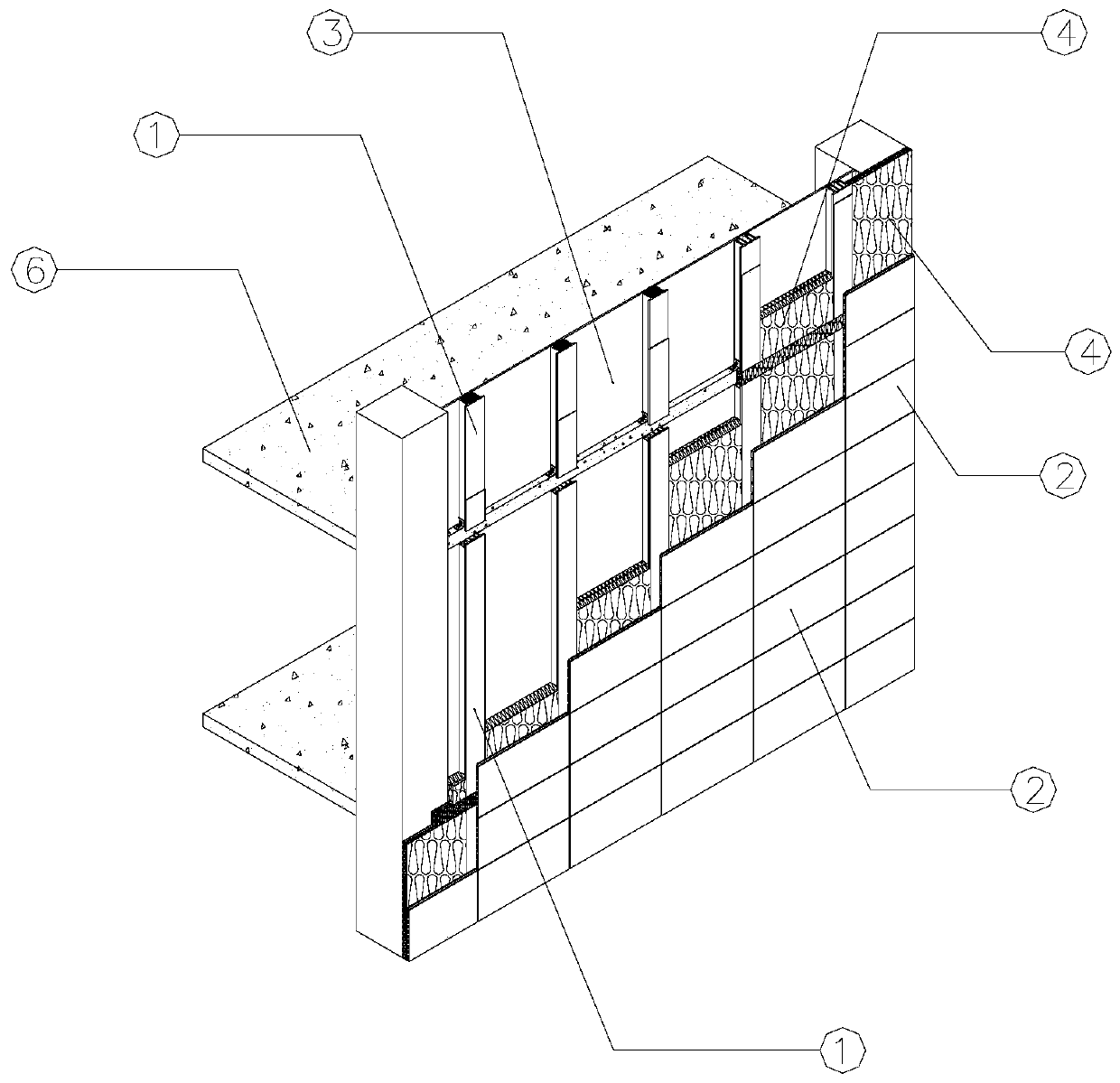

[0052] Combine below Figure 1-5 Describe in detail the technical solution for assembling the exterior wall with inorganic keel purlins:

[0053] An exterior wall assembled with inorganic keel purlins, including a main structure floor 6 and inorganic keel purlins 1, the inner cavity of the inorganic keel purlins 1 is filled with thermal insulation and sound insulation materials 4, and the inorganic keel purlins 1 are placed between the upper and lower main structure floors 6 by vertical vertically arranged and fixed on the corresponding positions of the upper and lower main structure floors 6 through connectors 5; between the two inorganic keel purlins 1, a vertically arranged inorganic material indoor side panel 3 is installed on one side of the indoor part, and the inorganic keel purlins The outer end of 1 is fixedly installed with horizontally arranged inorganic material outdoor side panels 2 through connectors 5, and a 5mm-20mm thick cold bridge isolation layer is sandwich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com