Rope winding gluing device for net rope processing

A gluing device and net rope technology, which is applied in the auxiliary device of rope making, the device of coating liquid on the surface, coating, etc., can solve the problems of poor gluing effect, improve the effect and ensure the quality of gluing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

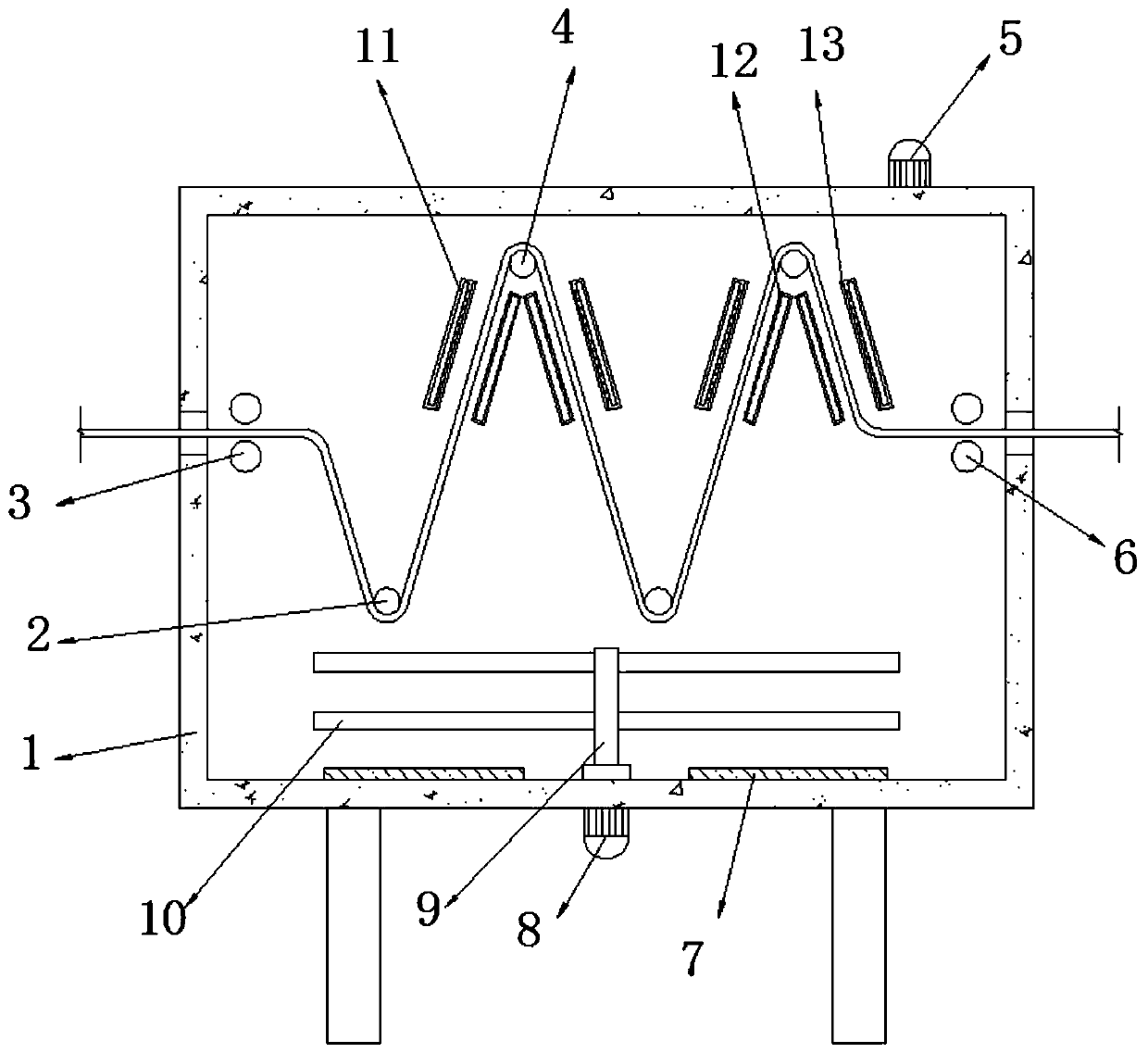

[0026] refer to Figure 1-3 , a rope winding glue coating device for net rope processing, comprising a box body 1, the left side of the inner wall on both sides of the box body 1 is connected with two feeding rollers 3 through bearings, and the bottom of the inner wall on both sides of the box body 1 is fastened by fastening bolts Two first limit rollers 2 are connected, and two second limit rollers 4 are connected to the top of the inner walls on both sides of the box body 1 through fastening bolts, and four a mounting plate 11, and two adjacent mounting plates 11 are respectively located on both sides of the adjacent second limit roller 4, and the outer wall of one side of the mounting plate 11 is connected with evenly distributed heating resistance wires 13 through fastening bolts, and installed The outer wall of one side of the plate 11 is provided with evenly distributed first air outlets 14, the outer wall of the top of the box body 1 is connected with the air pump 5 thr...

Embodiment 2

[0033] refer to Figure 4 , a rope winding glue coating device for net rope processing. Compared with Example 1, the inner walls of both sides of the box body 1 are connected with rubber scraping sleeves 17 by fastening bolts, and the net rope passes through the rubber scraping sleeves 17. .

[0034] Working principle: After the net rope rises from the glue, the rubber scraping sleeve 17 scrapes off the excess glue on the outer wall of the net rope to ensure even glue application.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com