Clothes drying method and clothes treatment device

A kind of clothing processing equipment and clothing technology, which is applied in household dryers, washing devices, textiles and papermaking, etc., can solve problems such as clothing damage, and achieve the effect of improving intelligence and specialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

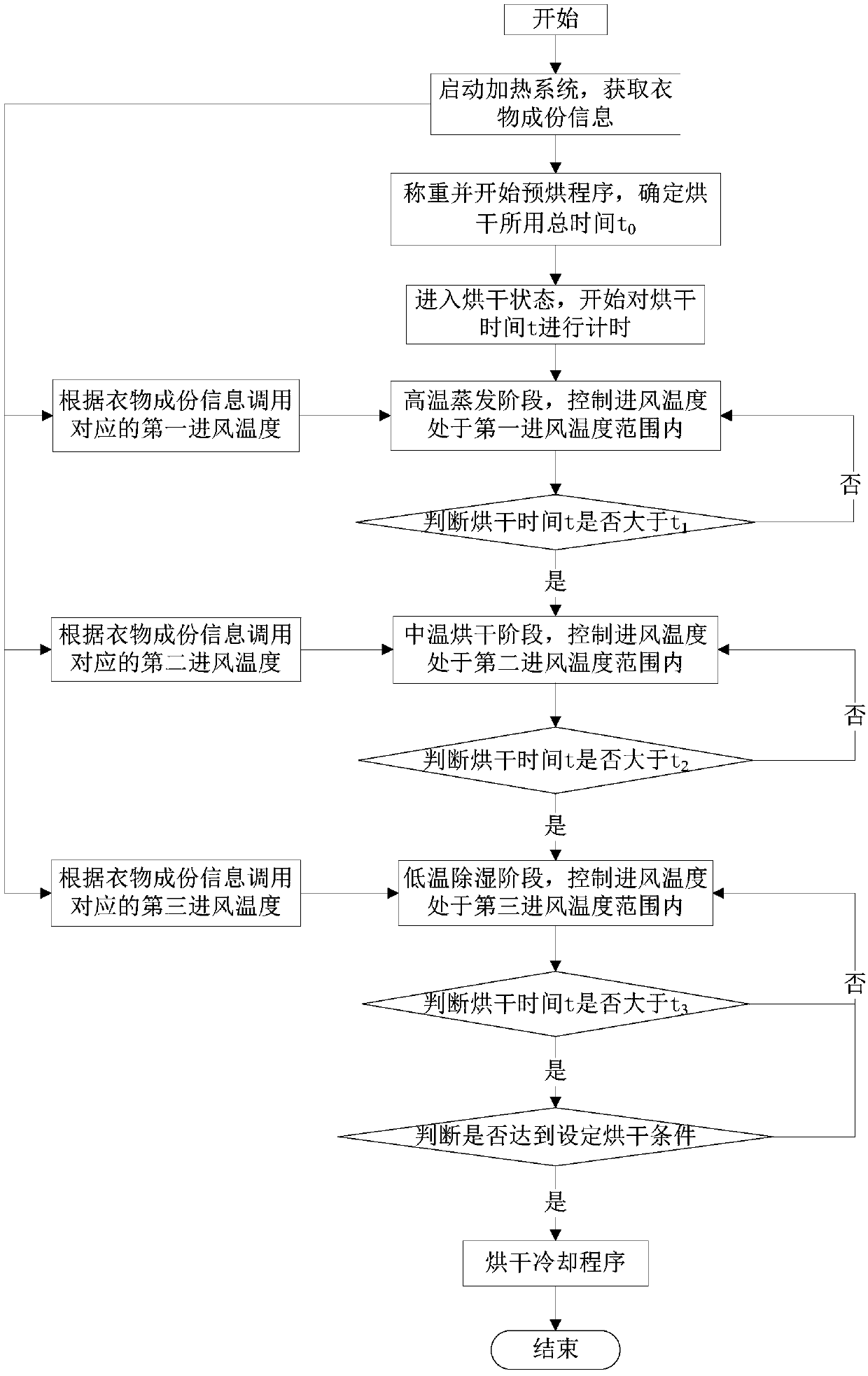

[0035] Such as figure 1 As shown, this embodiment introduces a method for drying clothes. During the drying and heating process, start the heating system and adjust the inlet air temperature to dry the clothes in stages. Each drying and heating stage adopts different inlet air temperature. It can be adjusted by controlling the inlet air temperature, and the drying heating process is divided into different stages according to the inlet air temperature. The rise causes the temperature of the clothes itself to be too high, and even causes the occurrence of damage to the clothes, which ensures that the temperature of the clothes itself is maintained within an appropriate range during the entire drying and heating process.

[0036] In this embodiment, the whole drying and heating process includes at least three drying and heating stages, each drying and heating stage is arranged in time sequence, and the temperature of the inlet air decreases successively.

[0037] In this embodi...

Embodiment 2

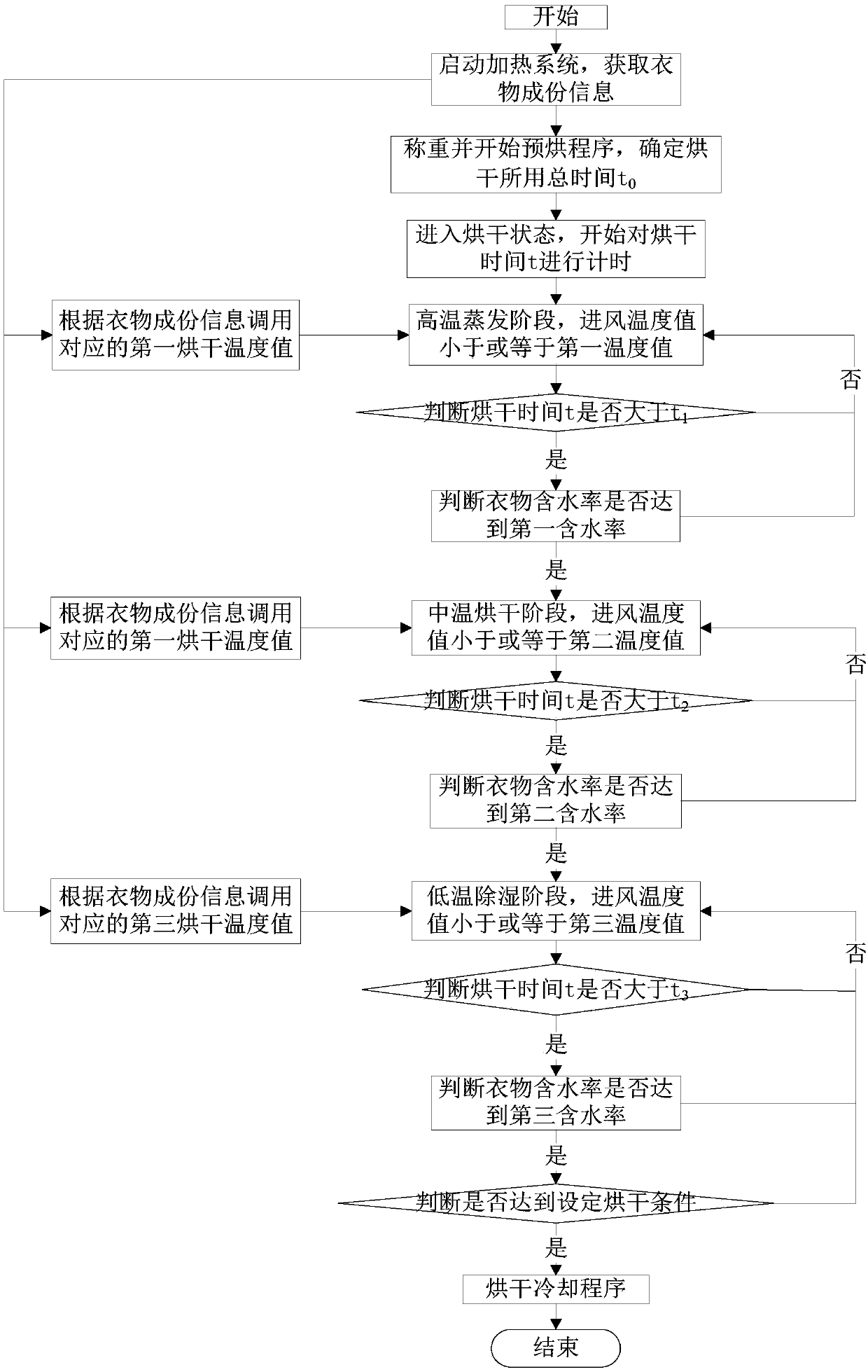

[0058] In this embodiment, different clothes materials correspond to the set drying coefficient values one by one, so as to call the corresponding first drying coefficient value, second drying coefficient value and third drying coefficient value after obtaining the clothing material information. value.

[0059] In this embodiment, during the drying and heating process, after the first drying time t 1 After that, the moisture content of the clothes reaches the first moisture content; after the second drying time t 2 After that, the moisture content of the clothes reaches the second moisture content; after the third drying time t 3 Afterwards, the moisture content of the laundry reaches the third moisture content. The relationship between each drying coefficient and the moisture content of the clothes is obtained through a large number of experiments. After t 1 (=t 0 × K 1 ) time, the moisture content of the clothes is reduced to 30%, after t 2 (=t 0 × K 2 ) time, the ...

Embodiment 3

[0075] In this embodiment, taking cotton clothes as an example, the method for drying clothes includes the following steps:

[0076] Step 1: Start the heating system, and obtain the clothing material information through the clothing material identification device;

[0077] Step 2: Weigh the clothes through the clothes weight detection device, and execute the pre-drying program, and calculate the total drying time t according to the material of the clothes, the load of the clothes and the pre-drying data obtained from the pre-drying program 0 , and then enter the drying state, and time the drying time t;

[0078] Step 3: High-temperature evaporation stage: According to the material of the clothes, the first air inlet temperature is determined to be 100°C-115°C, and the temperature of the air inlet is controlled to be within 100°C-115°C, and the clothes are evaporated at high temperature; at the same time, it is determined that the clothes under this material contain water When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com