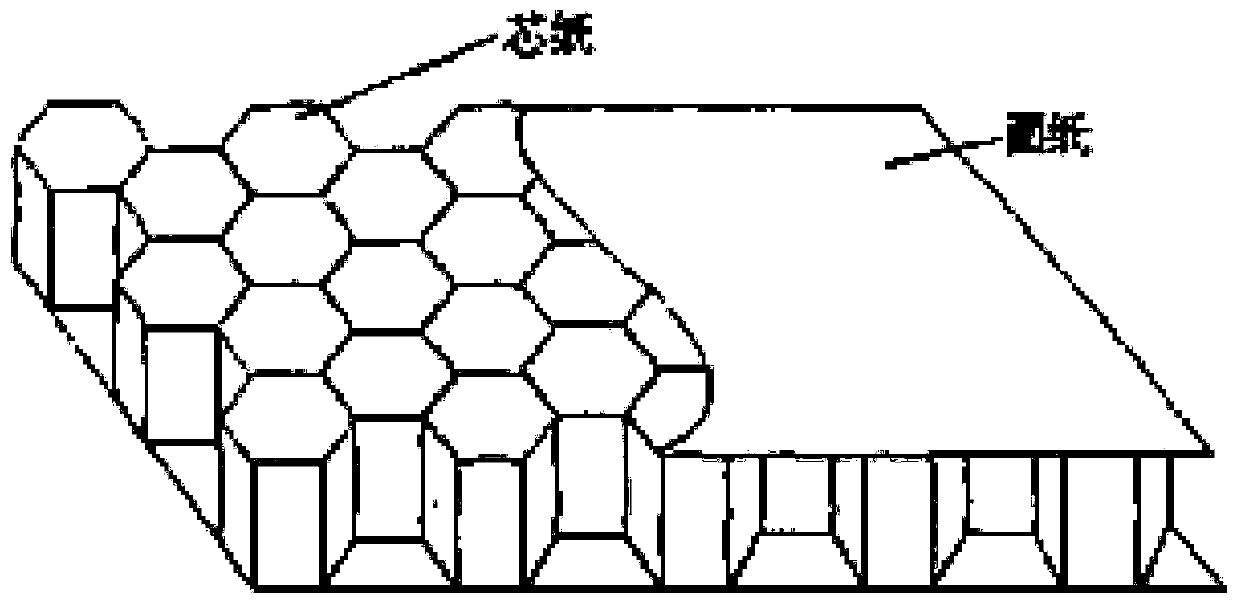

Honeycomb paperboard sandwich layer punching device and punching method thereof

A technology of honeycomb paperboard and sandwich layer, which is applied in the field of opening device for honeycomb paperboard sandwich layer, and the field of honeycomb paperboard sandwich layer opening device, which can solve the problems that the water cannot be completely dried and affects the production efficiency of honeycomb paperboard, etc. , to achieve the effect of overcoming the drying problem, strong implementability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

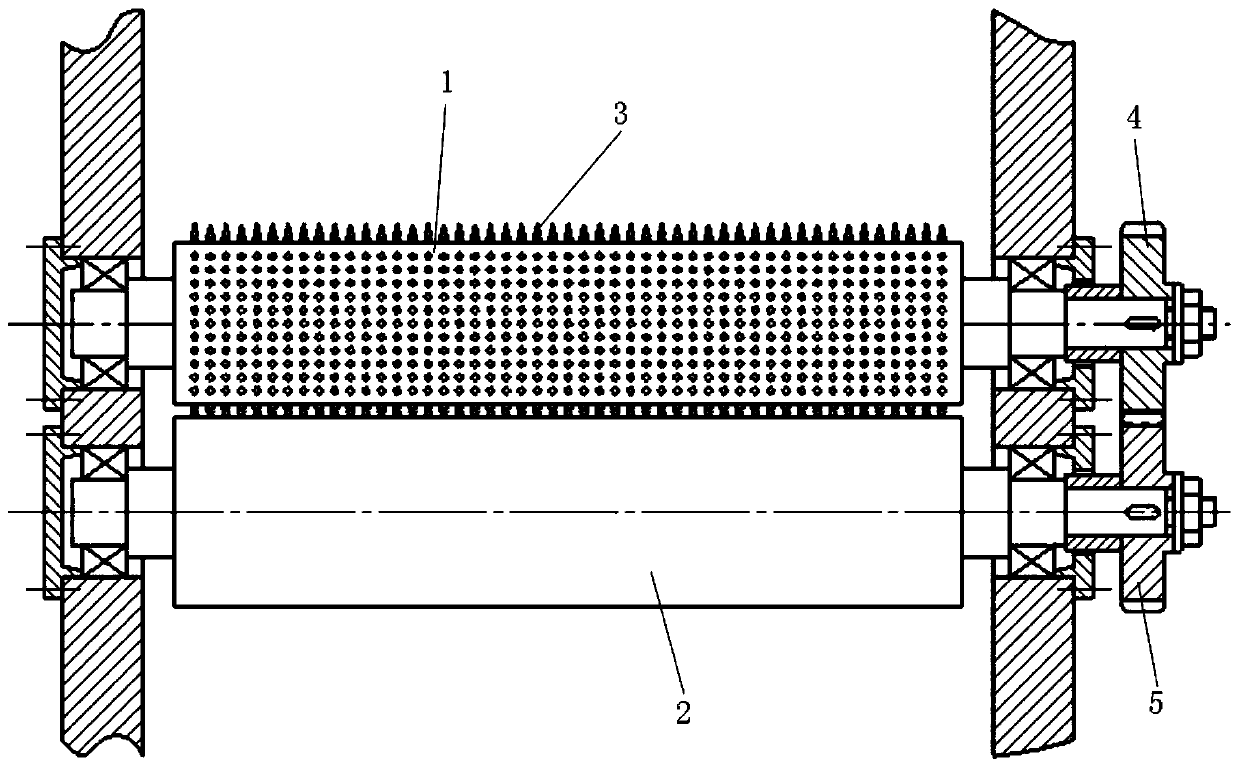

[0030] The invention relates to a device for opening holes in the sandwich layer of honeycomb paperboard, such as figure 2 As shown, it includes a pair of punching rollers 1 and paper guide rollers 2 that roll against each other. Both punching rollers 1 and paper guide rollers 2 are installed on the wallboard. It includes a steel roller body, the surface of which is covered with a hard rubber layer with a thickness of 5-10mm, and the same-side shaft ends of the perforated roller 1 and the paper guide roller 2 are respectively connected with a first gear 4 and a second gear 5 , the first gear 4 and the second gear 5 are equal in diameter and engaged, and the first gear 4 or the second gear 5 is connected with a motor with a reducer.

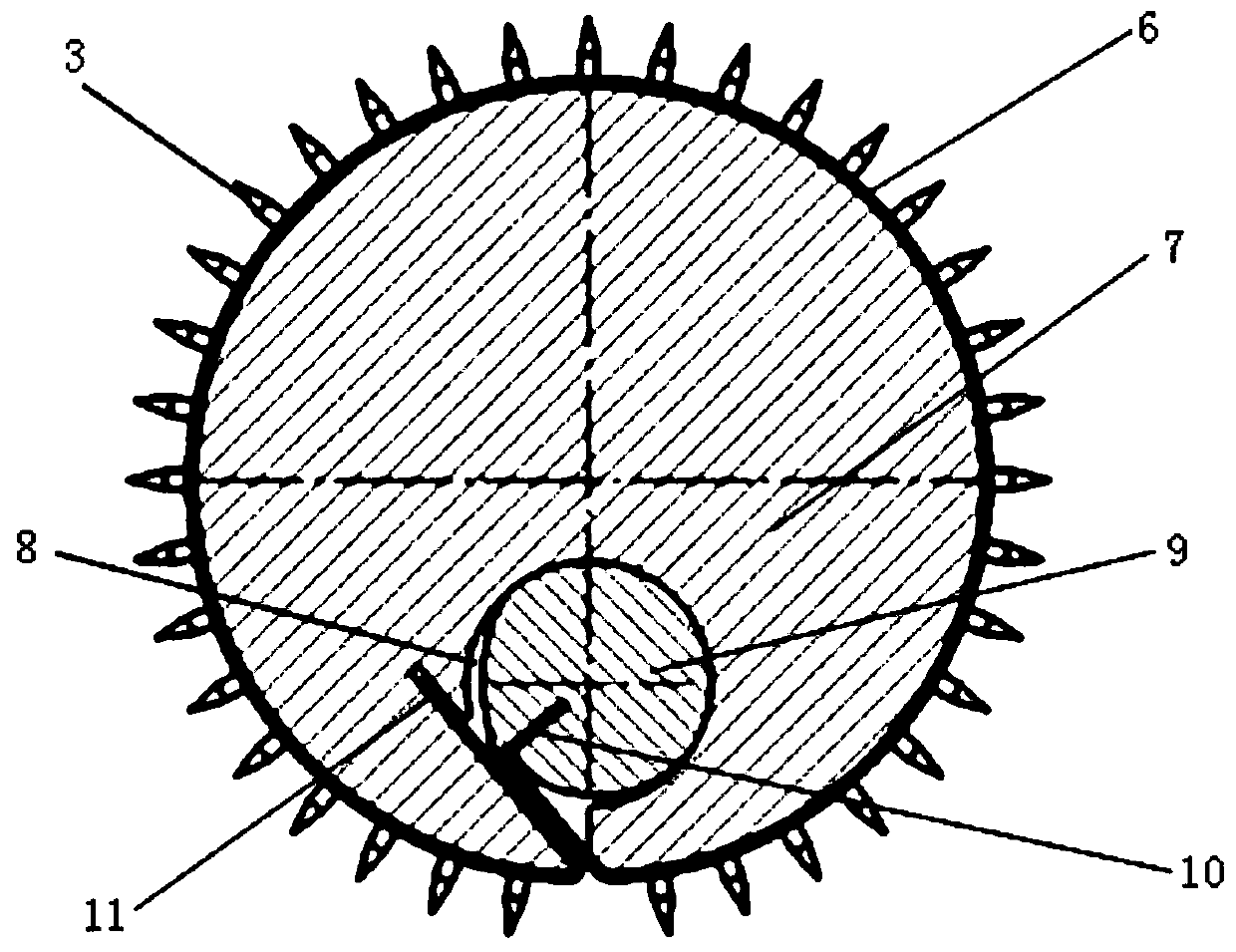

[0031] The structure of punching roller 1 comprises following three kinds:

[0032] The first type: the per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com