Falling-film material distributor and falling-film evaporation heater with falling-film material distributor

A material distributor and falling film evaporation technology, which is applied to evaporator accessories, evaporation, multi-effect evaporation, etc., can solve the problems of plug-type distributors with large flow resistance, high processing accuracy and installation requirements, and inconvenient installation and maintenance. The effect of small flow resistance, extended service life and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

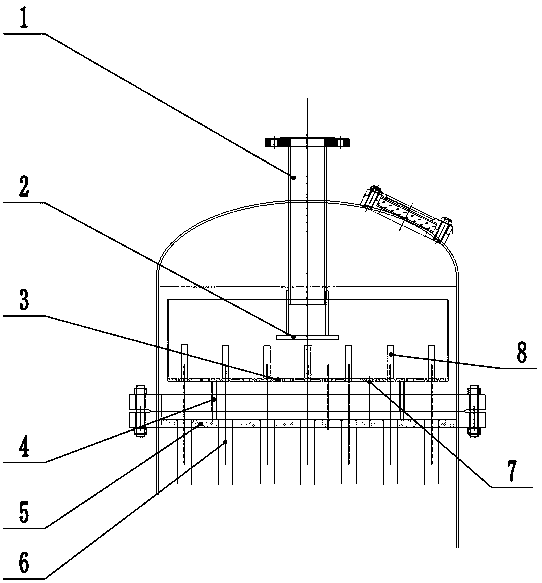

[0019] Accompanying drawing is a kind of specific embodiment of the present invention.

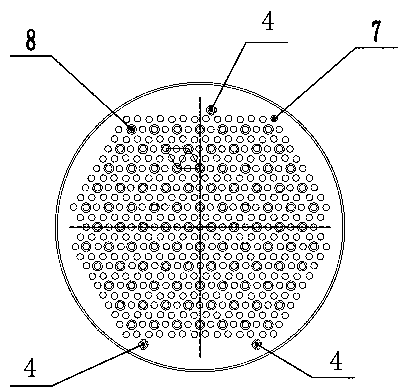

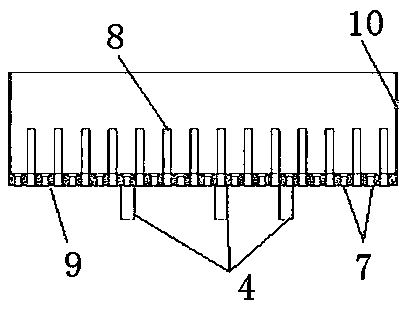

[0020] The falling film material distributor of the present invention comprises a bottom plate 9 and a cofferdam 10 fixed together, the cofferdam is fixed on the edge of the bottom plate and is located on the top of the bottom plate, a large number of upward balance pipes 8 are fixed on the bottom plate, and the balance pipes The inner hole communicates up and down with the through hole on the base plate, and a large amount of distribution holes 7 are arranged in the space of the balance pipe on the base plate, and several positioning pins 4 downward are fixed on the bottom of the base plate.

[0021] In the falling film material distributor, the bottom plate adopts a disc, and the three adjacent balance pipes 8 are distributed in an equilateral triangle.

[0022] The falling film evaporation heater of the present invention includes a tank body 11 and a large number of heat exchange tubes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com