Connection of elements in motor vehicles

A technology for motor vehicles and components, which is applied in the direction of connection between motor vehicles, vehicle parts, and superstructure subassemblies, and can solve problems such as high cost, restrictions, and difficulties in bonding components to each other, and achieve the effect of easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] exist figure 1 A body 10 of a motor vehicle is schematically shown in FIG. Body 10 here has a number of different structural parts, such as pillars 14 and struts 12 . These and other structures of the body 10 must be connected to one another by suitable means. In this case, in particular profiles, castings and plate-shaped elements can be connected to one another.

[0074] exist figure 2 A part of the first element 1 is schematically shown in . The first element 1 here has a groove 3 on its surface. At the same time, the surface of the first element 1 forms a shoulder 6 beside the recess 3 . The groove 3 here has a groove length 16 .

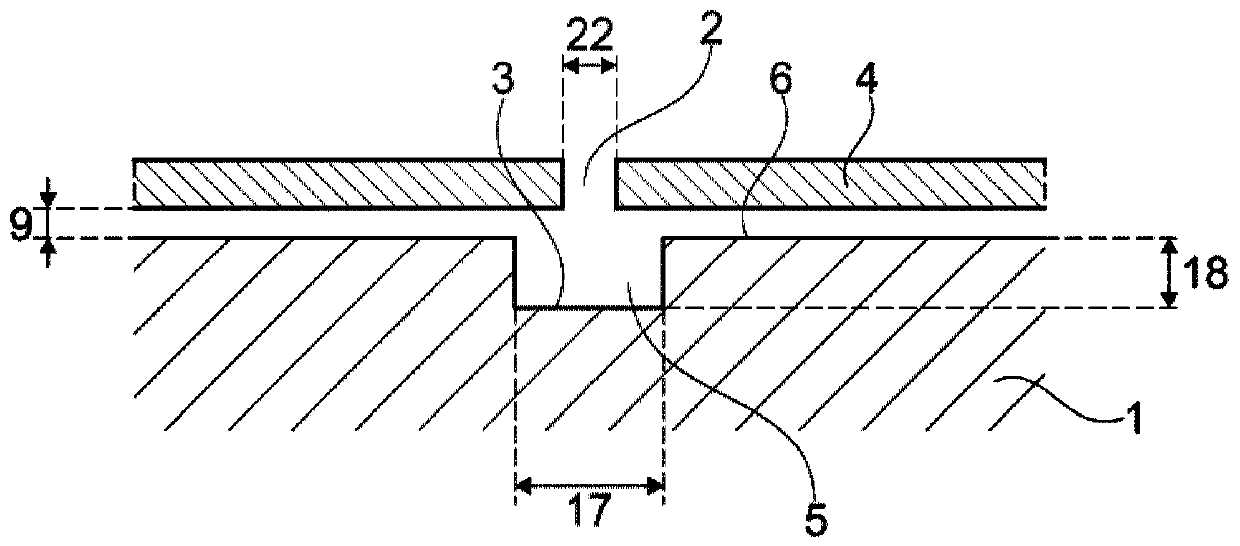

[0075] exist image 3 A partial cross-section of the first element 1 and the second element 4 is schematically shown in . The first element 1 again has a recess 3 formed on the surface of the first element 1 . The groove 3 here has a groove width 17 and a groove depth 18 . The cross section of the groove 3 is rectangular in thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com