Post-type multi-directional wire collector

A wire and column technology, applied in the field of wire collectors, can solve the problems of unstable conduction, easy loosening, and few lines, and achieve the effects of simple manufacture, beautiful structure and simple implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

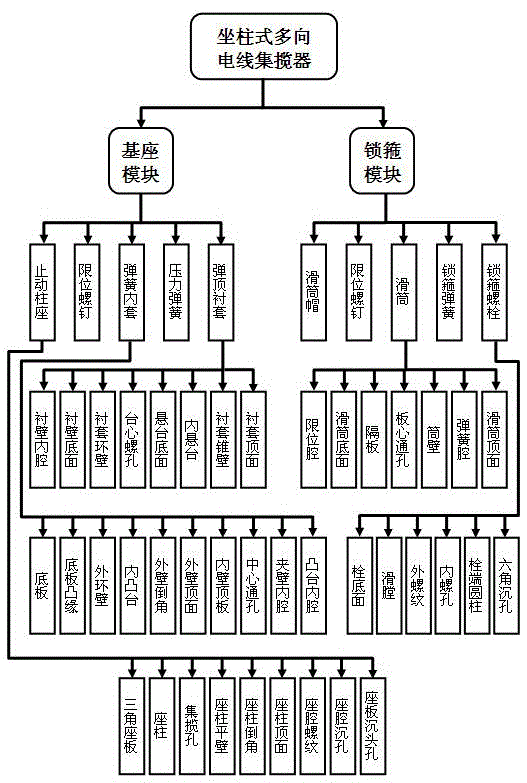

[0035] As a technical proposal for product manufacturing, the present invention can implement the proposal through the organic combination of corresponding organizational structures. The organizational structure of the product of an embodiment of the present invention is as figure 1 shown.

[0036] figure 1 Among them, the product is composed of two modules, the base and the lock hoop. The base module is composed of five parts: the stop post, the limit screw, the spring inner sleeve, the pressure spring, and the top bushing. The lock hoop module is composed of the slide It is composed of five parts: cylinder cap, limit screw, sliding cylinder, lock spring and lock bolt.

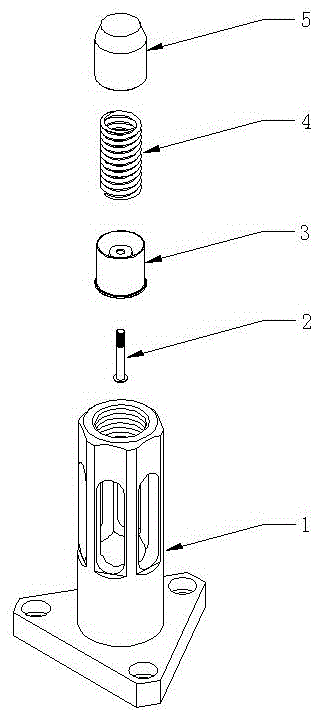

[0037] In the embodiment, each part has its own unique shape. The shape of the parts belonging to the base module is as follows: figure 2 shown.

[0038] figure 2 Among them, the parts arranged in the order of numbers are: stop column seat part (1), limit screw part (2), spring inner sleeve part (3), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com