Free ground film, circuit board and preparation method of free ground film

A printed circuit board, free technology, applied in the field of electronics, can solve the problems of affecting the signal transmission of the circuit board, unable to interfere with the export of charges, the connection failure between the free grounding film and the electromagnetic shielding film, etc., to achieve the effect of ensuring integrity and grounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

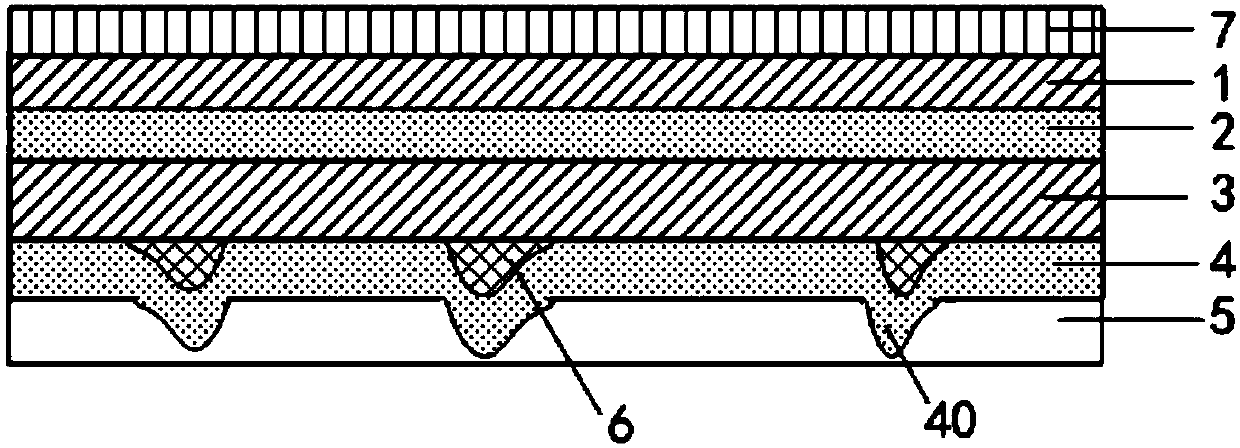

[0055] See figure 1 , the embodiment of the present invention provides a free grounding film, which includes a first conductor layer 1, a conductive adhesive layer 2 and a second conductor layer 3 stacked in sequence, and the second conductor layer 3 is far away from the conductive adhesive layer 2 There is a protrusion 6 on one side;

[0056] The free grounding film also includes a third conductor layer 4 and an adhesive film layer 5, the third conductor layer 4 is arranged on the side of the second conductor layer 3 on which the protrusion 6 is formed, and the third conductor layer A raised portion 40 is formed on the position where the conductor layer 4 covers the raised portion 6 (the relationship between the raised portion 40 and the raised portion 6 can be one-to-one correspondence, one-to-many correspondence or multi-to-one correspondence, etc., when the When the relationship between the raised portion 40 and the raised portion 6 is a one-to-one correspondence, the sha...

Embodiment 2

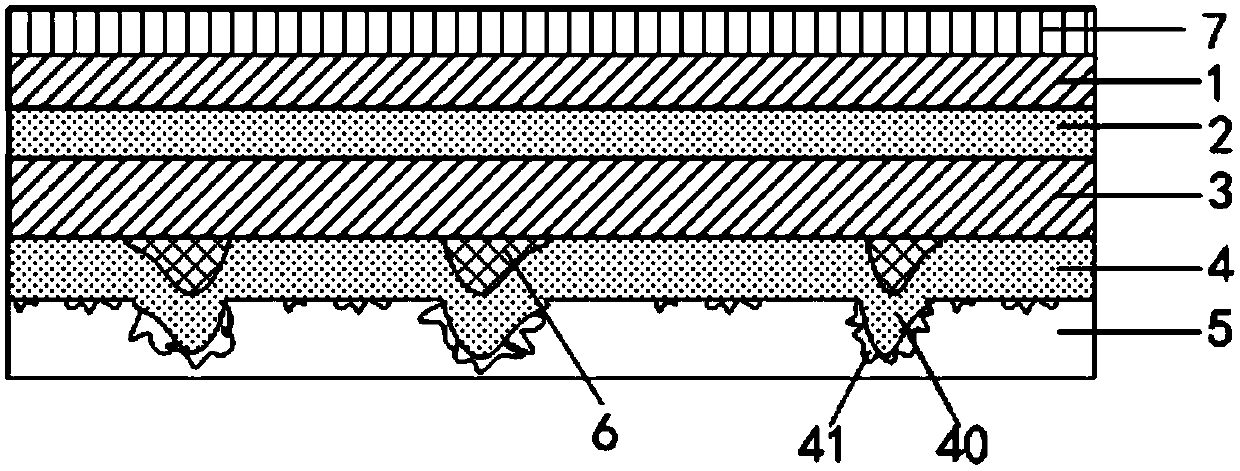

[0078] See figure 2 , this embodiment provides another free grounding film, which differs from the first embodiment mainly in that: the surface of the raised portion 40 is provided with convex conductor particles 41 . Wherein, by arranging the conductor particles 41 on the surface of the raised portion 40, it is further ensured that the raised portion 40 can smoothly penetrate the adhesive film layer 5 and the electromagnetic shielding during the pressing process. The insulating layer 80 of the film 8 further ensures the normal derivation of disturbing charges.

[0079] In the embodiment of the present invention, the height of the conductor particles 41 is preferably 20 μm-100 μm, the thickness of the adhesive film layer 5 is preferably 0.1 μm-80 μm, and the thickness of the insulating layer 80 is preferably 1 μm-20 μm. By setting the height of the conductive particles 41 to preferably 20 μm-100 μm, the thickness of the adhesive film layer 5 is preferably 0.1 μm-80 μm to ens...

Embodiment 3

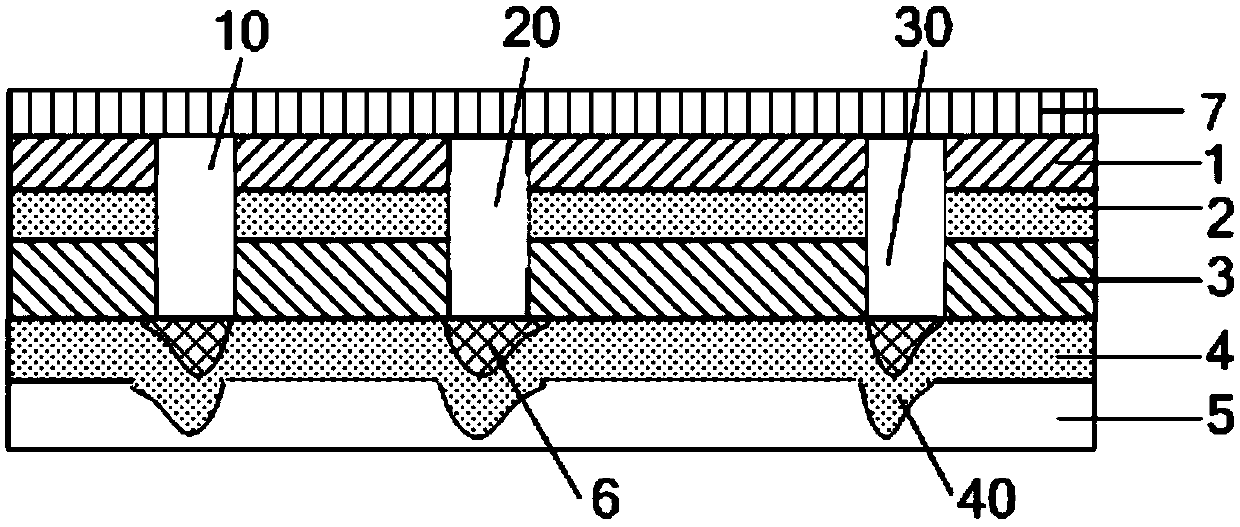

[0085] See image 3 and Figure 5 , this embodiment provides another free grounding film, which differs from Embodiment 1 and Embodiment 2 mainly in that: the formation process of the protrusion 6 is: the first conductor layer 1 is provided with a The first through hole 10 on the surface, the second conductor layer 3 is provided with a second through hole 30 passing through its upper and lower surfaces, and the protrusion 6 is made of fluid resin from the first through hole 10 through the second through hole 30. The conductive adhesive layer 2 is solidified when flowing to the outside of the second through hole 30 .

[0086] Specifically, as image 3 As shown, the protrusion 6 is formed by solidification when the fluid resin flows from the first through hole 10 through the conductive adhesive layer 2 to the outside of the second through hole 30, specifically as follows: The conductive adhesive layer 2 is provided with a third through hole 20 penetrating through its upper an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com