A device and method for testing the acoustic performance of products

An acoustic performance and product technology, which is applied in the field of devices for testing the acoustic performance of products, can solve problems such as inconsistent performance of the sound emitting surface of the speaker, no sealing and isolation, and burnout of the sound source, so as to prevent distortion or damage to the sound source and ensure sound quality. The pressure performance is consistent and the effect of isolating external environmental noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

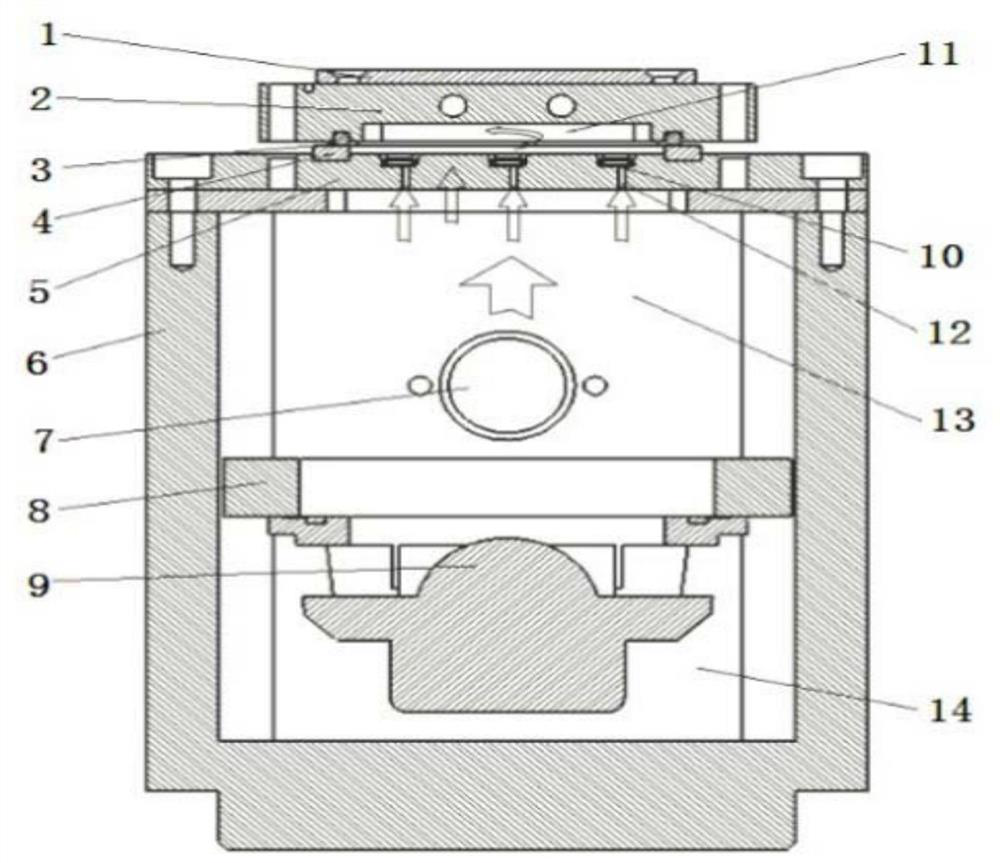

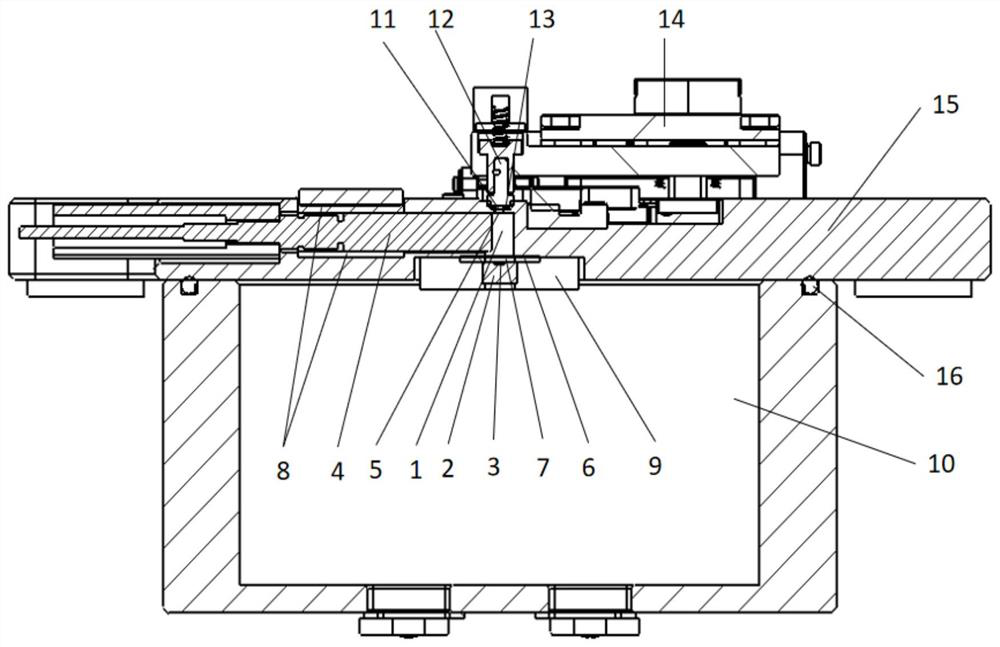

[0020] Such as figure 2 As shown, the technical solution of the disclosed embodiment of the present invention is as follows: a device for testing the acoustic performance of a product, including a carrying mechanism, the carrying mechanism is composed of a carrying platform 15, a sound source speaker 2, a speaker fixing seat 9, and a speaker rear cavity 10. Refer to the composition of the microphone 4 and the sealing ring, which is characterized in that: the carrying platform 15 is provided with a cavity 1, and the two ends of the cavity 1 are provided with a sound inlet 7 and a sound outlet 5, and the sound outlet 5 The relative position is provided with a product groove; the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap