Miniature ultra-low capacitance solid discharge tube and manufacturing method thereof

A solid discharge tube, ultra-low technology, applied in circuits, thyristors, electrical components, etc., can solve the problem of insufficient chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

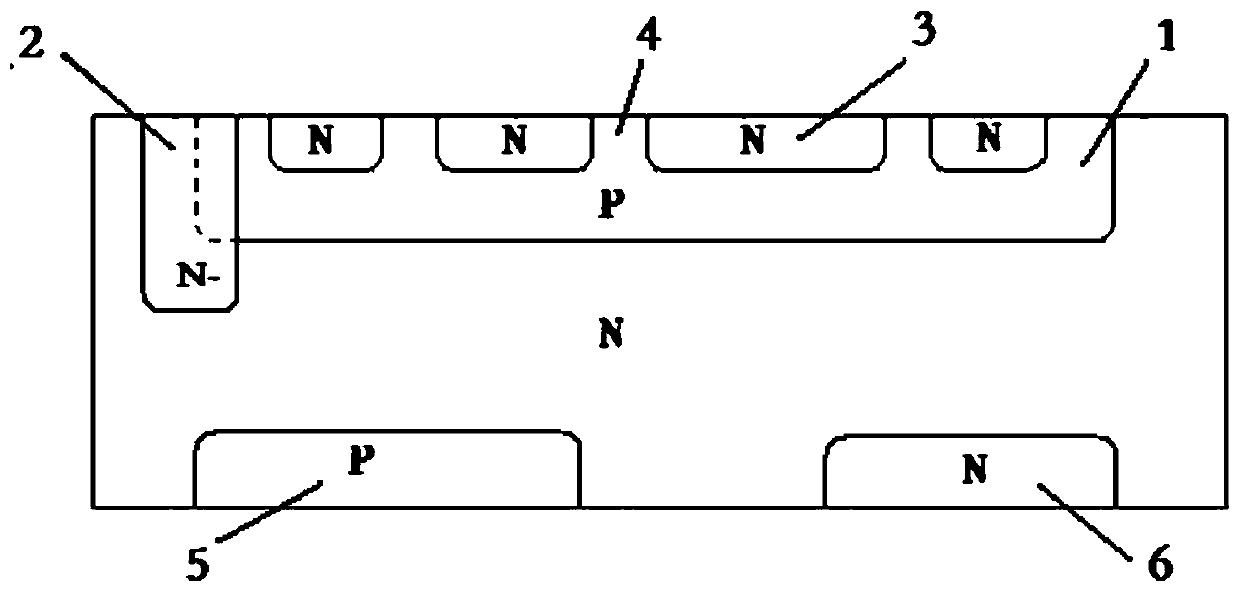

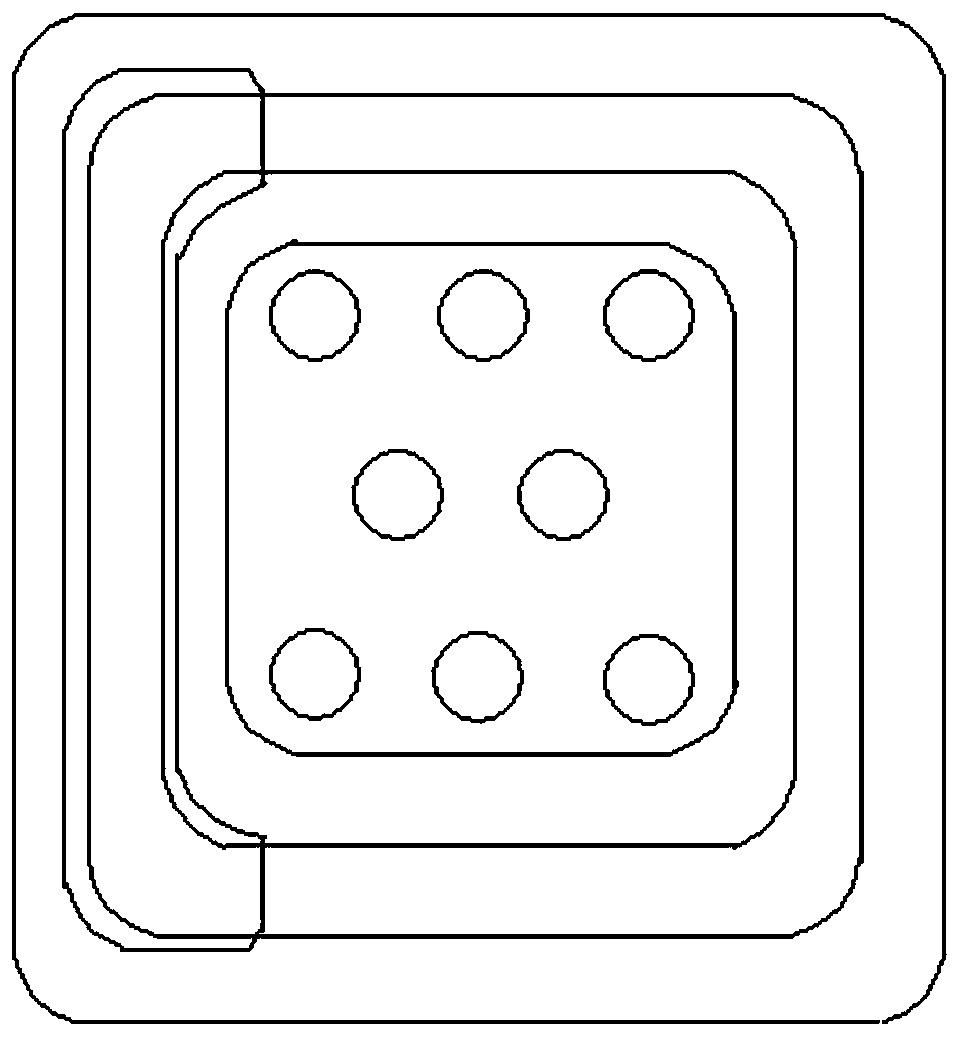

[0028] A miniature ultra-low capacitance solid discharge tube, the microchip area is 0.56mm*0.56mm, such as figure 2 , 3 As shown, it includes the upper boron-based region P1 and the lower boron-based region P5, and a phosphorus diffusion region N+3 is respectively arranged in the upper boron-based region P1 to form a cellular cathode; the boron-based region P1 and the boron-based region P5 The junction depth is 20--25μm. A boron region P5 and a second phosphorus diffusion region N+6 are arranged below, and the positions of the two regions are independently laid out, and the junction depth of the boron region is 20--25μm.

[0029] In the present invention, the junction capacitance of the ultra-low capacitance is less than 6pF.

[0030] In the present invention, a metal layer is provided on the outside of the upper boron base region P1 and the lower ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Junction capacitance | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com