An isolating switch conductive structure composed of special-shaped aluminum tubes

A special-shaped aluminum tube, isolating switch technology, applied in the direction of air switch parts, contact electrical connection, etc., can solve the problems of inconvenient assembly, complex structure, etc., and achieve the effects of convenient installation, large contact area, and fast heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

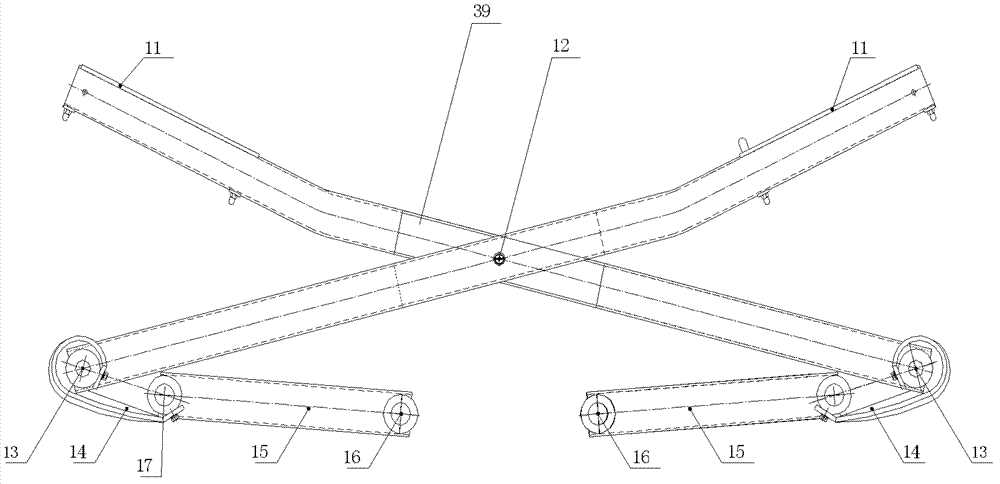

[0021] see Figure 1 to Figure 6 As shown, the conductive structure of the isolating switch composed of a special-shaped aluminum tube in the present invention includes: 2 upper conductive parts 11 and 2 lower conductive parts 15. The 2 upper conductive parts 11 are connected symmetrically through the middle rotating shaft pin 12 to form an X shape ; Then 2 pieces of lower conductive parts 15 are connected to the upper conductive parts 11 respectively through connecting shaft pins 13 . A pin shaft 17 is installed at one end of the lower conductive part 15 , and an end shaft 16 is installed at the other end, and the pin shaft 17 is connected to the corresponding shaft pin 13 through two side plates 18 . In order to ensure that the connection between the upper conductive part 11 and the lower conductive part 15 can flow reliably, four copper strips 14 are used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com