Temperature control large-size geotechnical true triaxial multi-field coupling test system and method

A test system, large-scale technology, applied in the direction of soil material testing, material inspection products, using a stable tension/pressure test material strength, etc., can solve the difficult multi-field coupling effect, large scale effect of the specimen, no Consider temperature control, large size and multi-field coupling to achieve the effect of easy control, multi-functionality and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

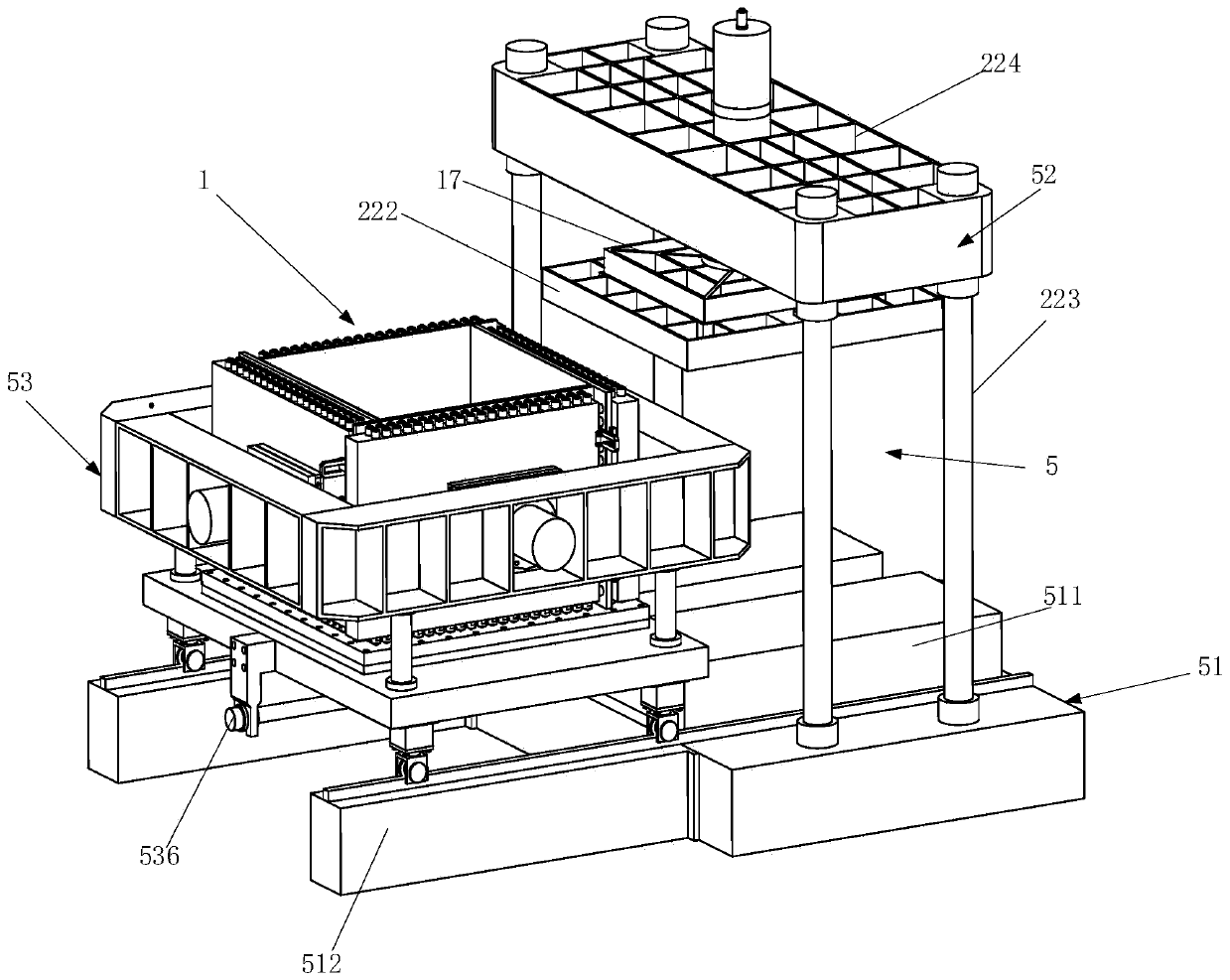

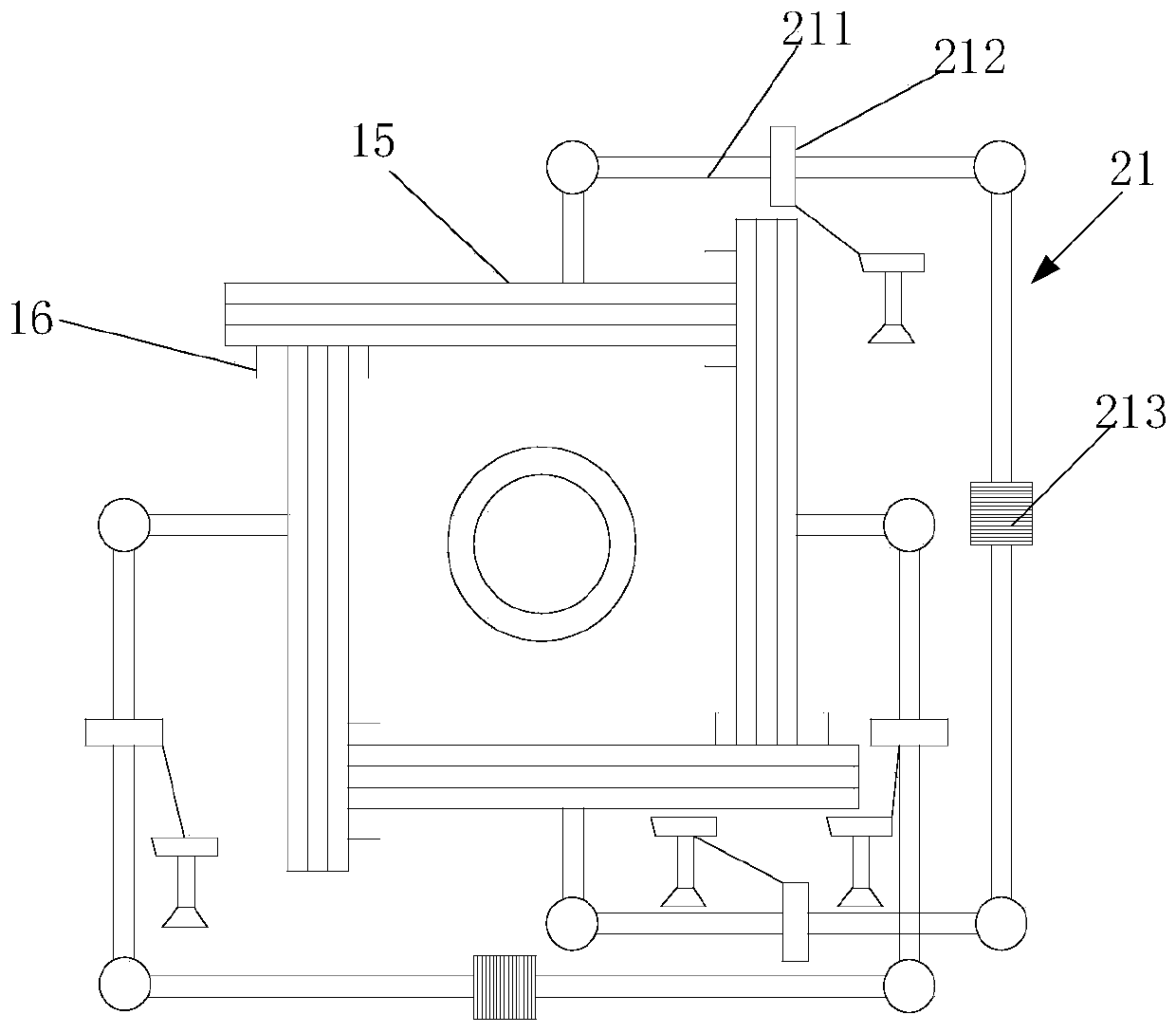

[0042] Embodiment 1, a temperature-controlled large-scale geotechnical true triaxial multi-field coupling test system, including a host loading mechanism 5, a deformable large-scale soil box 1, an independent three-dimensional loading unit, a refrigeration and water and salt supply unit, and a soil-water - ice-salt change monitoring unit, such as figure 1 As shown, the deformable large-scale soil box 1 is set on the main engine loading mechanism 5, and the independent three-dimensional loading unit, refrigeration and water-salt supply unit and soil-water-ice-salt change monitoring unit are all connected with the deformable large-scale soil box. The tanks are connected to realize the monitoring of stress application, refrigeration and water and salt replenishment, and soil-water-ice-salt changes respectively.

[0043] refer to figure 1 , the host loading mechanism 5 includes a load base 51, a vertical load frame 52 and a horizontal load frame 53, the load base 51 and the verti...

Embodiment 2

[0052] Embodiment 2. Based on the geotechnical true three-axis multi-field coupling test system disclosed in Embodiment 1, this embodiment specifically introduces the assembly method as follows:

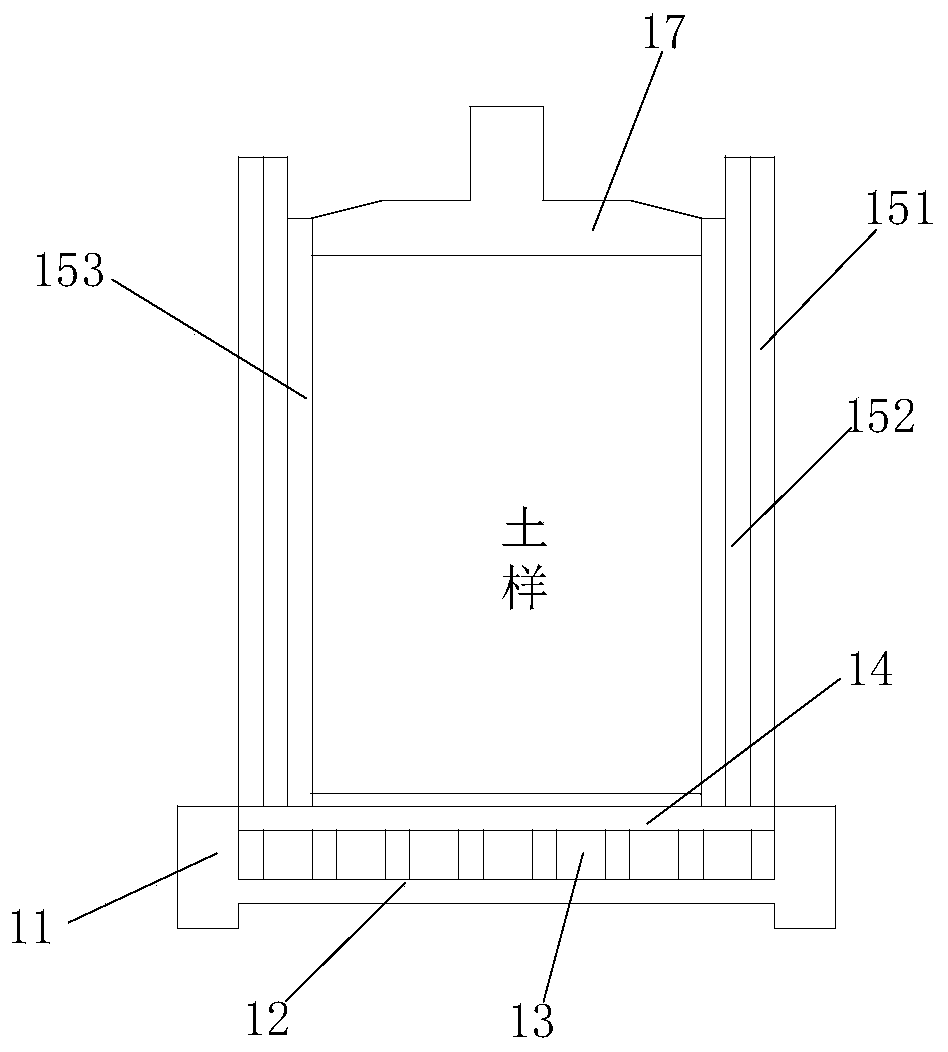

[0053] Step 1: Install the base, bottom plate, water supply and drainage groove and permeable plate in sequence;

[0054] The bottom plate is placed on the base, and the water supply and drainage groove is arranged on the bottom plate. The water supply and drainage groove is mainly composed of steel columns and a sloped bottom plate. There is a water supply and drainage port in the middle of the bottom plate. Evenly replenish the soil sample through the permeable plate;

[0055] Step 2: Install the side panels of the soil box, complete the assembly of the soil box according to the horizontal deformation limit device of the soil box, and arrange waterproof sealing strips between the side panels of the soil box and between the side panels and the bottom panel;

[0056] In order to pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com