Oxygen-free sectional type pyrolysis furnace for household garbage

A domestic waste and pyrolysis furnace technology, which is applied in the field of domestic waste anaerobic segmental pyrolysis furnace, can solve the problems of secondary pollution of operating costs, avoid rapid loss of heat, improve utilization rate, and reduce dioxins The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

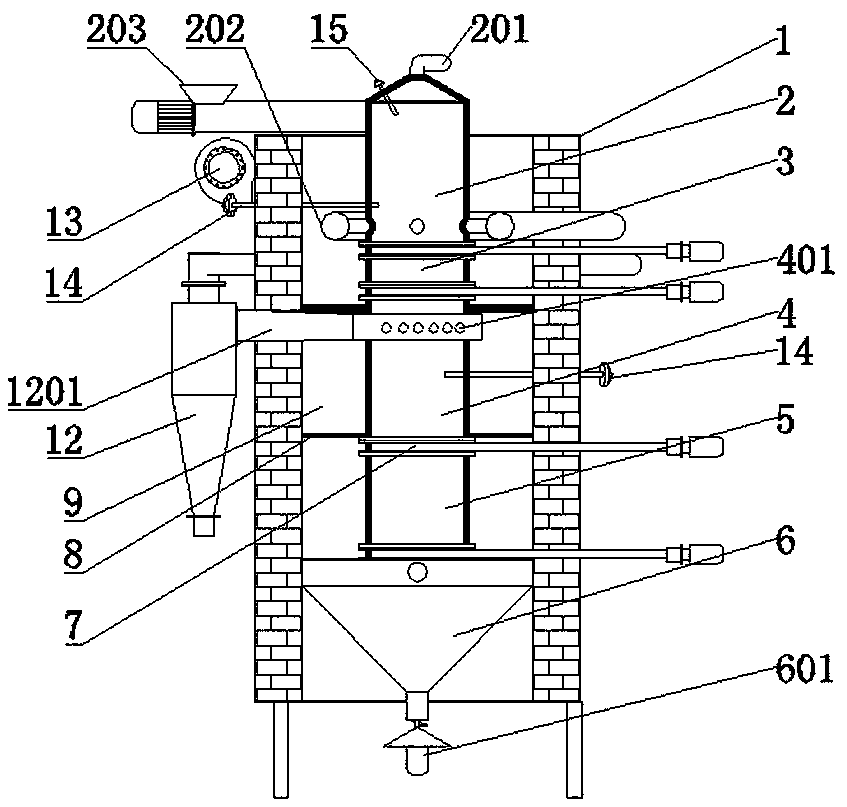

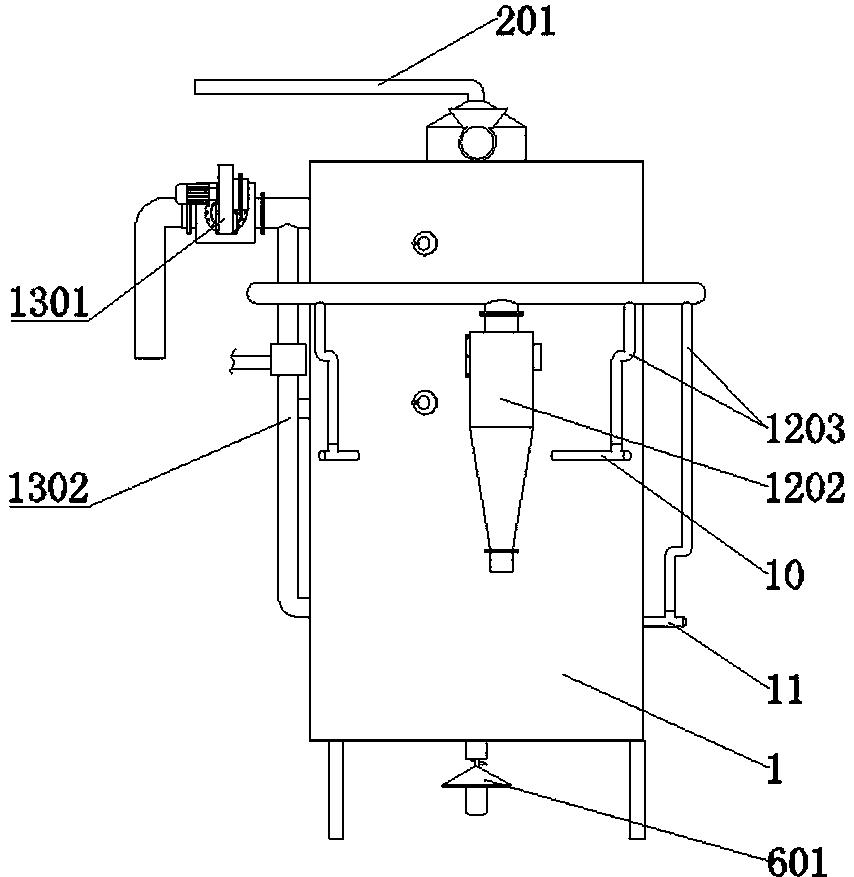

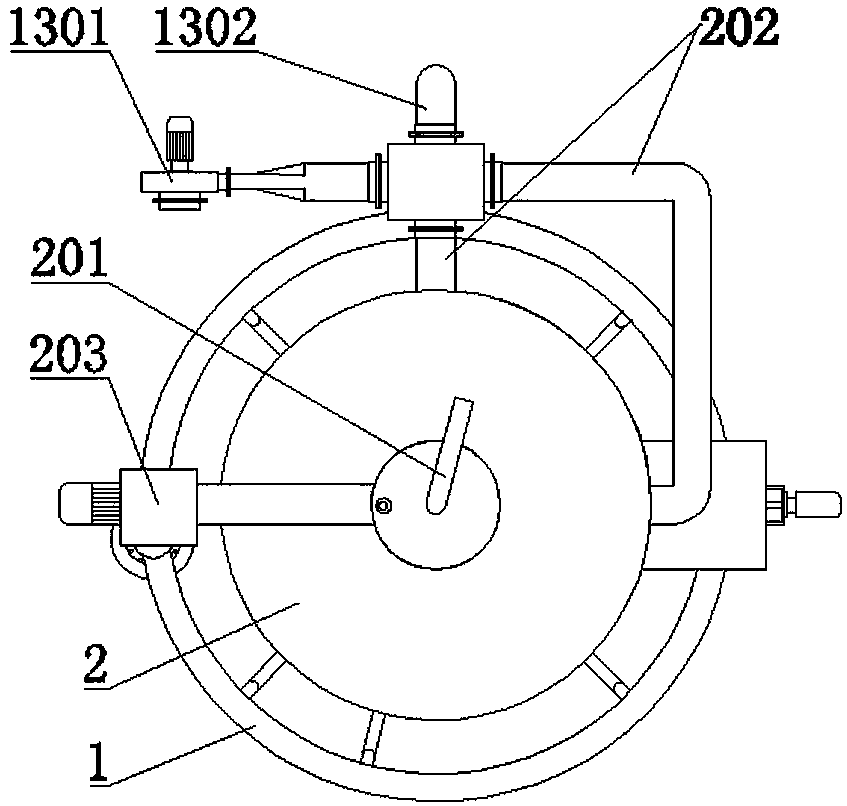

[0015] Such as figure 1 , figure 2 with image 3 As shown, the domestic waste anaerobic segmented pyrolysis furnace includes a heat preservation furnace body 1, a drying furnace body 2, a heat insulation furnace body 3, a pyrolysis furnace body 4, a carbon stripping furnace body 5, an ash hopper 6, and a drying furnace body Body, heat insulation furnace body, pyrolysis furnace body, carbon stripping furnace body, and ash hopper are fixedly arranged in the holding furnace body from top to bottom, and drying furnace body, heat insulation furnace body, pyrolysis furnace body, carbon stripping furnace body 1. There are heat-insulating inserts 7 between the ash hoppers, and the drying furnace body is used for drying domestic garbage. The heat-insulating section furnace body can separate the high-temperature pyrolysis furnace body from the drying furnace body, and the heat-insulating section furnace body can ensure The temperature of the body is controllable. The pyrolysis furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com