A kind of environment-friendly feed production system and feed production process method

A production system and environment-friendly technology, applied in the direction of feed, food science, application, etc., can solve the problems affecting the quality of the final product, harmful to the health of the staff, and pollution of the production environment, so as to improve the production environment, improve easy rolling, and reduce runaway. scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

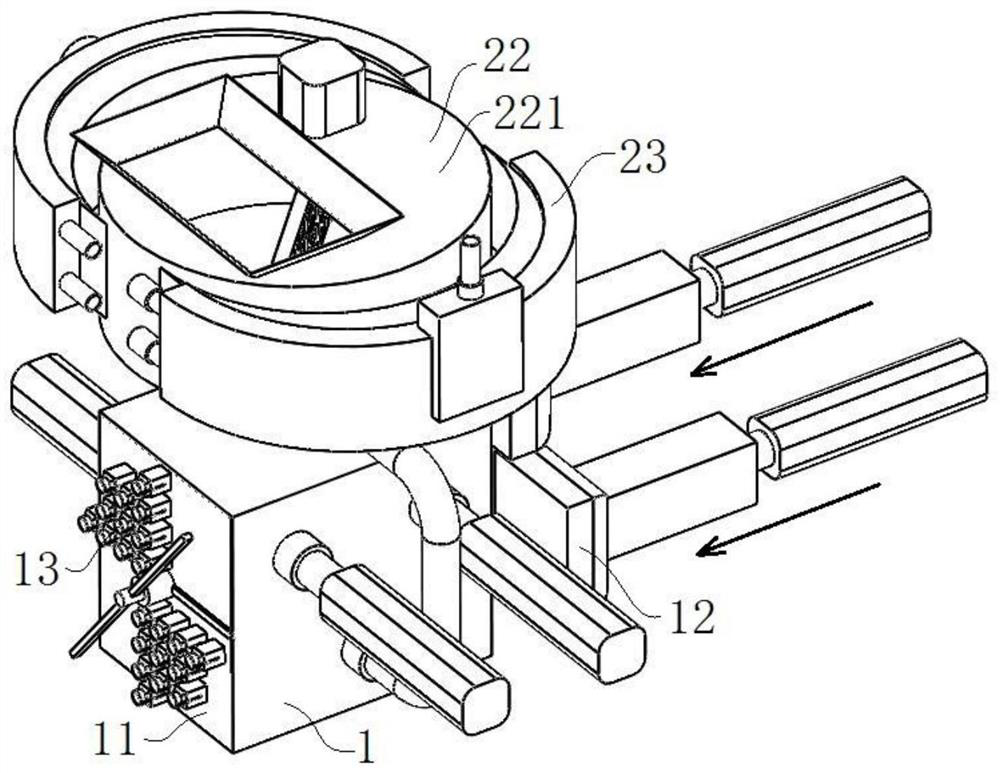

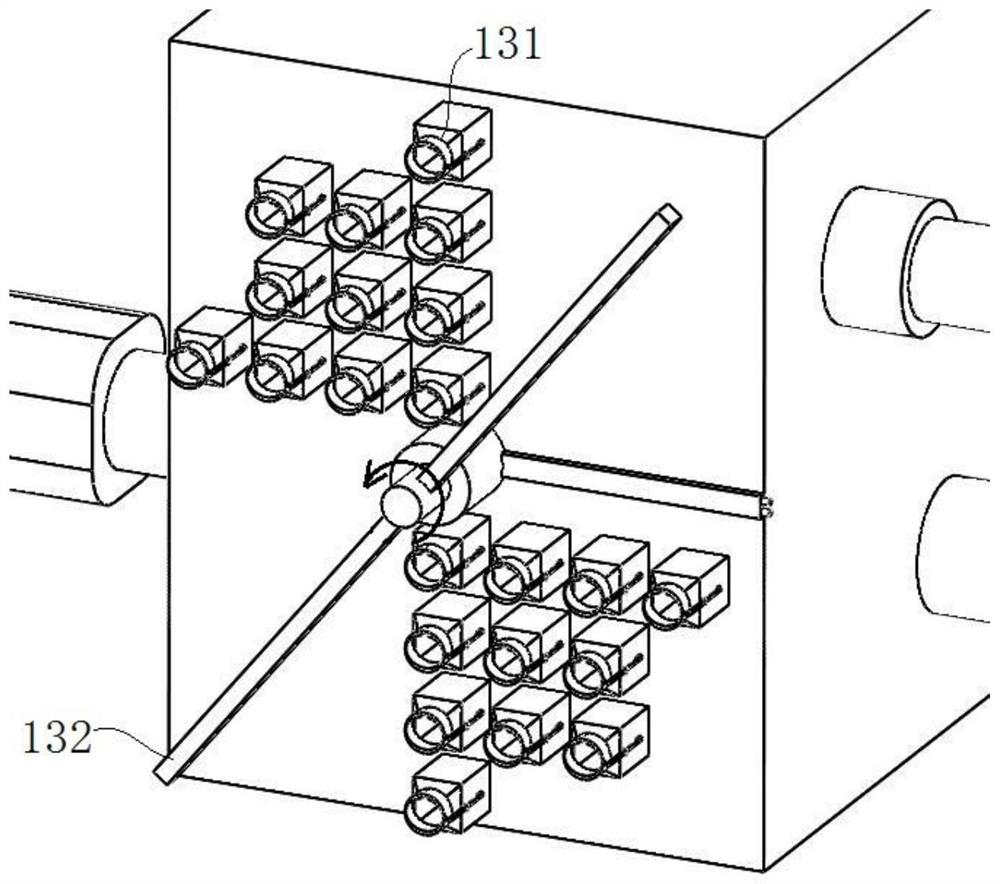

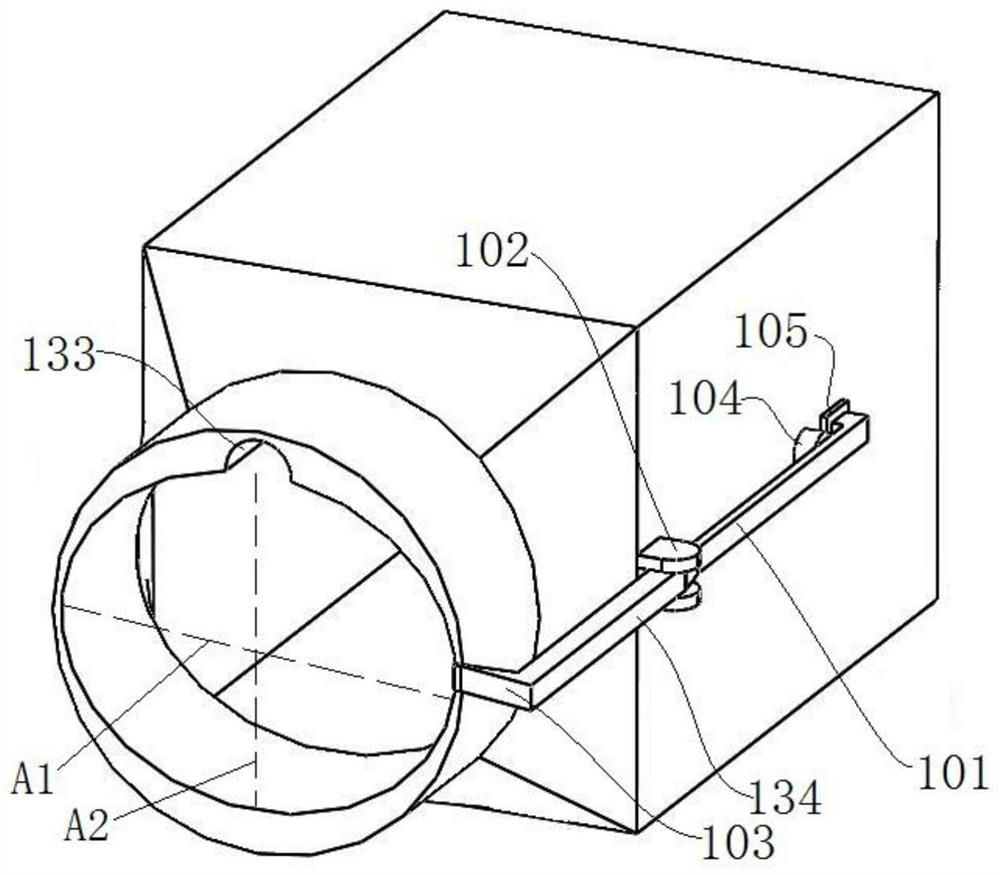

[0026] An environment-friendly feed production system, comprising a pelletizing unit 1; as attached figure 1 As shown, the granulation unit 1 includes a material cavity 11, a pressure head 12 and a molding assembly 13; the material cavity 11 is filled with raw materials, and the raw materials are transported to the material cavity 11 by the bin body 221, and the bin body 221 is transported and used The height difference between the material chamber and the material cavity 11 makes the raw material continue to fall under the action of gravity, and at the same time, the material valve is used to cooperate with the telescopic action of the pressure head 12 to realize periodic feeding; Both sides of the cavity 11; the press head 12 is nested with the material cavity 11, and the press head 12 moves back and forth along the embedding direction to extrude the raw material fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com