Preparation method of filter membrane section sample

A filter membrane and cross-section technology, applied in the field of sample preparation, can solve problems such as uneven incision and damage to the pore structure, and achieve the effect of easy operation and smooth cross-section of the filter membrane.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

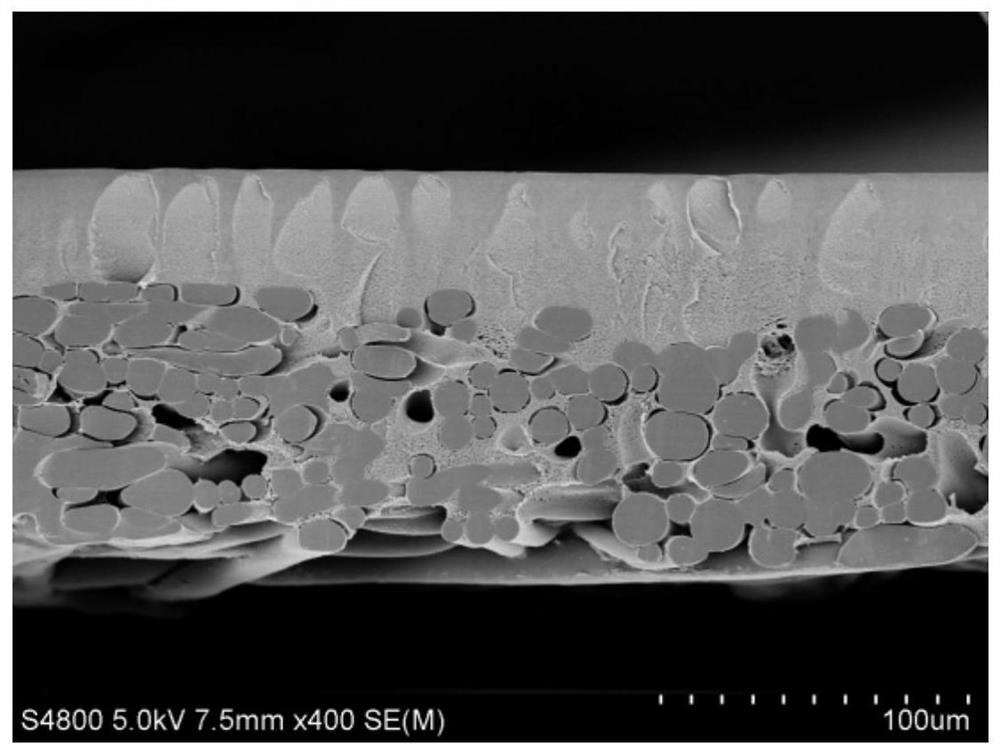

[0046] Take the filter membrane, the filter membrane is an ultrafiltration membrane, the functional layer is polyethersulfone (PES), the support layer is a non-woven fabric (PE), and the aperture is 2-100nm. After immersing in ultrapure water for 0.5h, wait for frozen section When the temperature of the cooling chamber drops below -20°C, the temperature of the cold head drops below -30°C, the temperature of the cold knife drops below -20°C, and the temperature of the cold table drops below -35°C, the filter membrane is fixed with a mold Put it on the sample stage in the freezing chamber of the cryostat, and the filter membrane extends in a straight line and is perpendicular to the plane of the sample stage. Add water to the mold so that the water does not pass through the filter membrane, and then lower the temperature so that the filter membrane and water freeze and solidify together, then remove the mold, so that the filter membrane is vertically frozen on the sample stage, a...

Embodiment 2

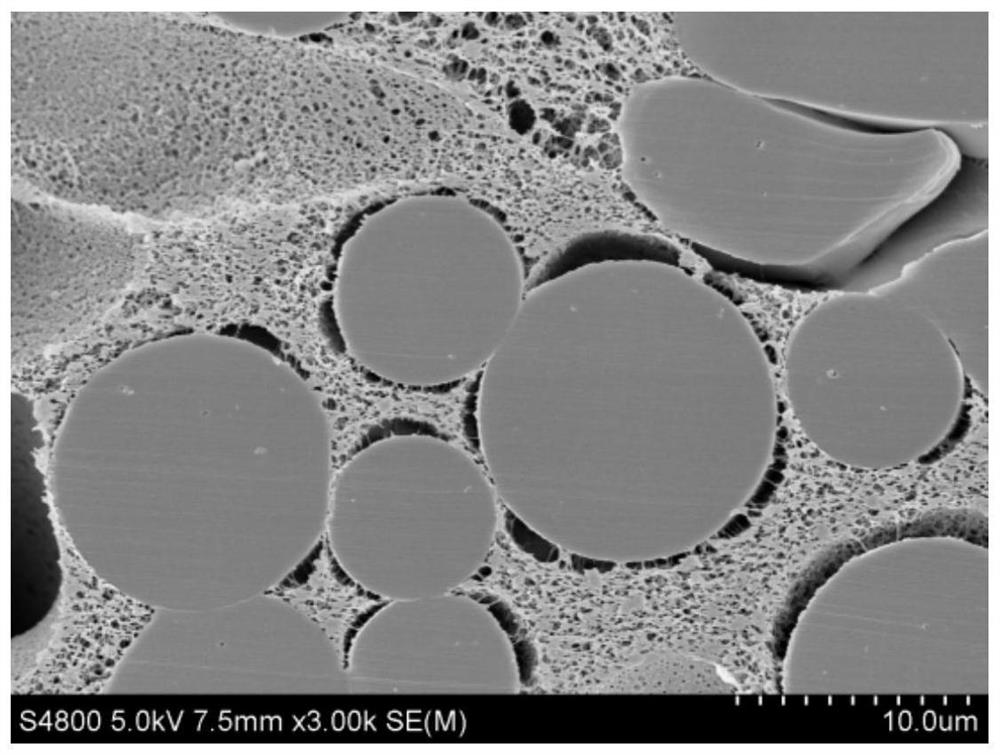

[0051] Get the filter membrane, the filter membrane is a microfiltration membrane, the functional layer is polyvinylidene fluoride (PVDF), the support layer is non-woven fabric (PE), and the aperture is 0.1-1 μm. After soaking in ultrapure water for 0.5h, wait for When the temperature of the cold chamber of the frozen microtome drops below -20°C, the temperature of the cold head drops below -30°C, the temperature of the cold knife drops below -20°C, and the temperature of the cold table drops below -35°C, the filter The membrane is fixedly placed on the sample stage in the freezer chamber of the cryostat, and the filter membrane extends in a straight line and is perpendicular to the plane of the sample stage. Add water to the mold so that the water does not pass through the filter membrane, and then lower the temperature so that the filter membrane and water freeze and solidify together, then remove the mold, so that the filter membrane is vertically frozen on the sample stage,...

Embodiment 3

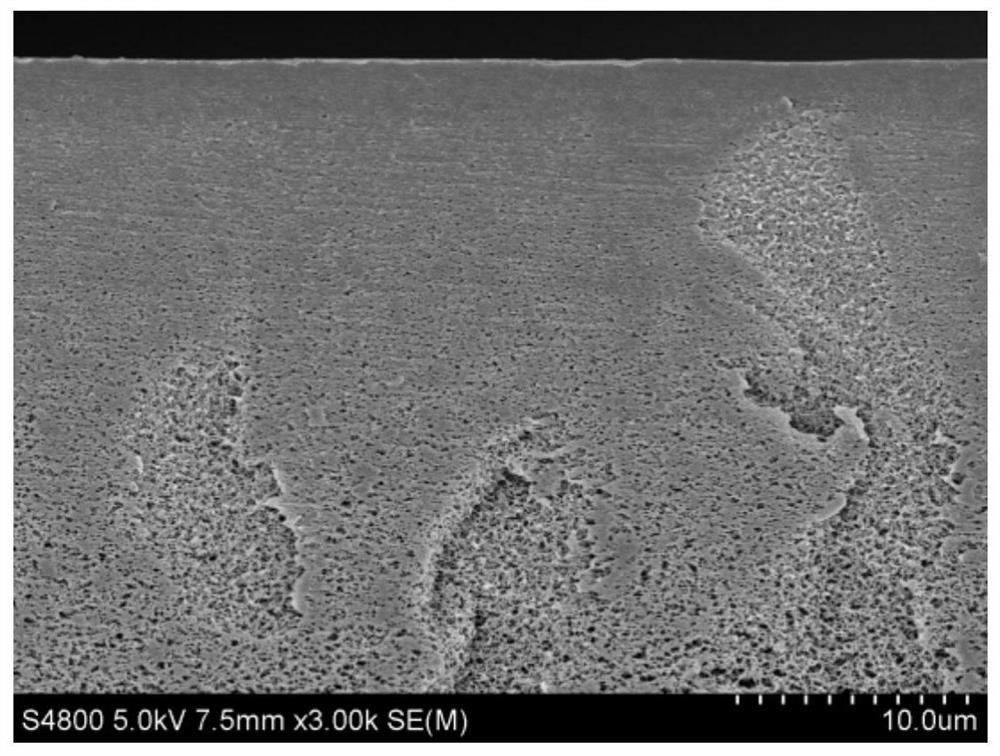

[0056] Take the filter membrane, the filter membrane is a microfiltration membrane deposited on the surface to filter pollutants, the functional layer is polyvinylidene fluoride (PVDF), the support layer is non-woven fabric (PE), and the pore size is 0.1-1 μm. After soaking for 0.5h, when the temperature of the cold chamber of the frozen microtome drops below -20°C, the temperature of the cold head drops below -30°C, the temperature of the cold knife drops below -20°C, and the temperature of the cold table drops below -35°C, The filter membrane is fixed and placed on the sample stage in the freezer chamber of the cryostat with a mould, and the filter membrane extends in a straight line and is perpendicular to the plane of the sample stage. Add water to the mold so that the water does not pass through the filter membrane, and then lower the temperature so that the filter membrane and water freeze and solidify together, then remove the mold, so that the filter membrane is vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com