Preparation method for modified high-density polyethylene resin used for bottle cap

A high-density polyethylene and modification technology, which is applied in the field of preparation of modified high-density polyethylene resin for bottle caps, can solve the problems of general mechanical strength and easy cracking of plastic bottle caps, and achieve improved bonding effect, smooth cross-section and strengthened Effects of Using Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

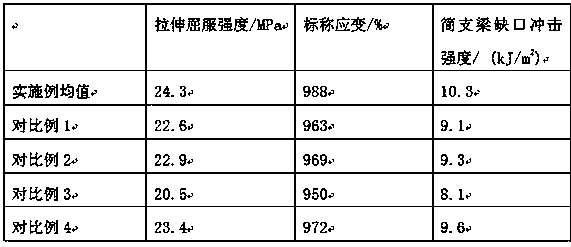

Examples

Embodiment 1

[0021] A method for preparing a modified high-density polyethylene resin for bottle caps, comprising the following steps:

[0022] (1) Preparation of organic modifier:

[0023] Dissolve 4-aminopyridine in hydrochloric acid solution, stir at room temperature for 10 minutes, then lower the temperature to -1.5°C, keep it warm for 15 minutes, then raise the temperature to 8°C, keep it warm, and then dissolve sodium nitrite and phenol in a mass fraction of 8% sodium hydroxide solution to obtain a mixed solution, slowly drop the mixed solution into the hydrochloric acid solution of 4-aminopyridine, react at 8°C for 45min, and then adjust the reaction system with a 15% sodium hydroxide solution pH to 6.8, standing for 1 hour, filtering the reaction product, washing the reaction product, and drying in vacuum to obtain p-hydroxyazopyridine;

[0024] (2) Preparation of inorganic modifier:

[0025] Dissolve ammonium metavanadate in deionized water at a temperature of 80°C to prepare an...

Embodiment 2

[0036] A method for preparing a modified high-density polyethylene resin for bottle caps, comprising the following steps:

[0037] (1) Preparation of organic modifier:

[0038] Dissolve 4-aminopyridine in hydrochloric acid solution, stir at room temperature for 15 minutes, then lower the temperature to -1.5°C, keep it warm for 15 minutes, then raise the temperature to 8°C, keep it warm, and then dissolve sodium nitrite and phenol in a mass fraction of 8% sodium hydroxide solution to obtain a mixed solution, slowly drop the mixed solution into the hydrochloric acid solution of 4-aminopyridine, react at 8°C for 45min, and then adjust the reaction system with a 15% sodium hydroxide solution pH to 6.8, standing for 1 hour, filtering the reaction product, washing the reaction product, and drying in vacuum to obtain p-hydroxyazopyridine;

[0039] (2) Preparation of inorganic modifier:

[0040] Use ammonium metavanadate to dissolve in deionized water at a temperature of 80°C to pre...

Embodiment 3

[0051] A method for preparing a modified high-density polyethylene resin for bottle caps, comprising the following steps:

[0052] (1) Preparation of organic modifier:

[0053] Dissolve 4-aminopyridine in hydrochloric acid solution, stir at room temperature for 12 minutes, then lower the temperature to -1.5°C, keep it warm for 15 minutes, then raise the temperature to 8°C, keep it warm, and then dissolve sodium nitrite and phenol in a mass fraction of 8% sodium hydroxide solution to obtain a mixed solution, slowly drop the mixed solution into the hydrochloric acid solution of 4-aminopyridine, react at 8°C for 45min, and then adjust the reaction system with a 15% sodium hydroxide solution pH to 6.8, standing for 1 hour, filtering the reaction product, washing the reaction product, and drying in vacuum to obtain p-hydroxyazopyridine;

[0054] (2) Preparation of inorganic modifier:

[0055] Use ammonium metavanadate to dissolve in deionized water at a temperature of 80°C to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com