A kind of livestock and poultry manure cleaning device

A cleaning device, a technology for livestock and poultry manure, which is applied in the poultry industry, animal husbandry, poultry cages or houses, etc., can solve the problems of increasing the resistance of the manure scraping unit, increasing the pulling force of the traction rope and unevenness, and reducing the fatigue stress. Damage, improve work efficiency, reduce the effect of resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

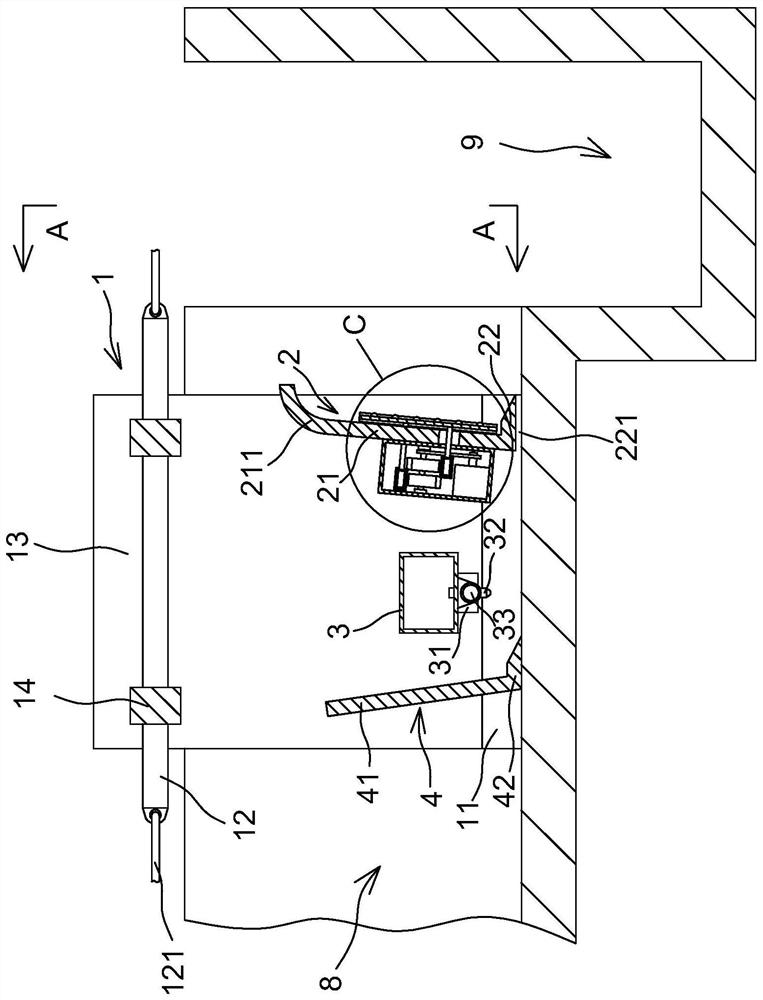

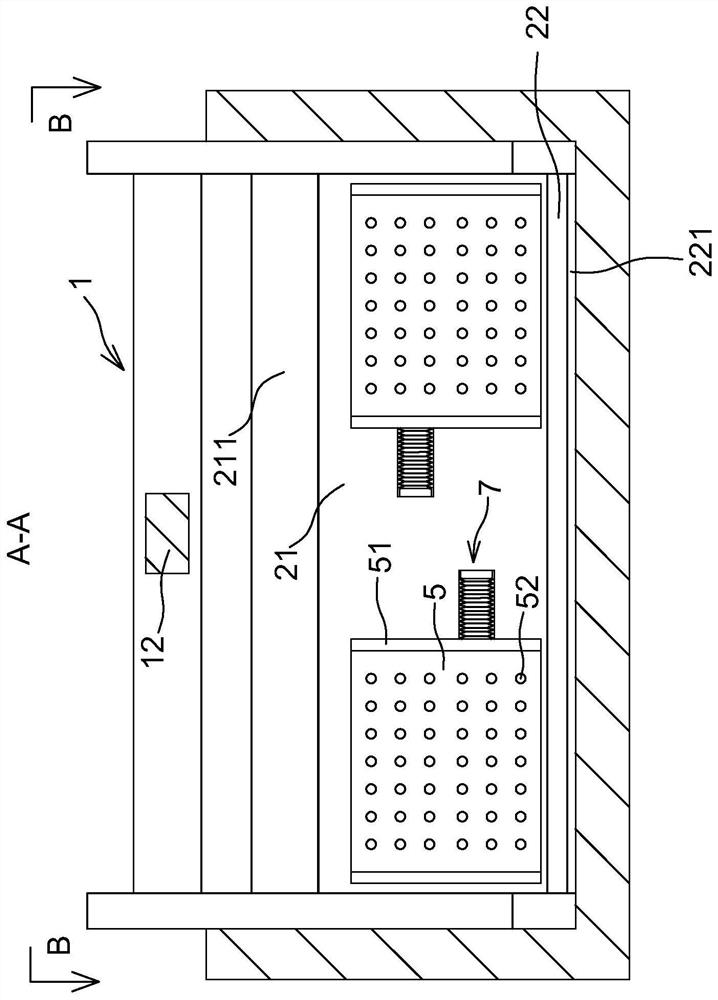

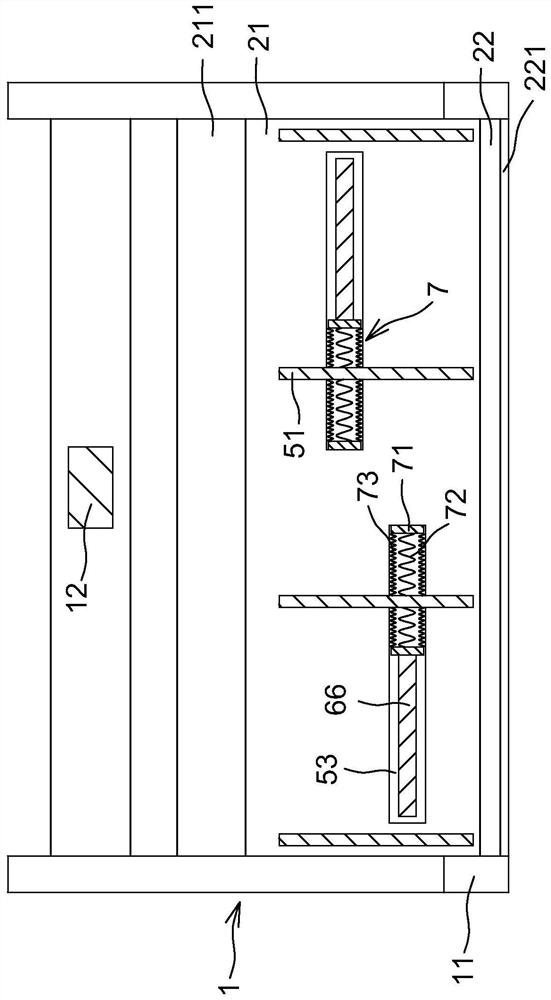

[0035] refer to figure 1 , figure 2 and Figure 5 , a livestock and poultry manure cleaning device, including a frame 1 installed in a manure ditch 8 that matches the inner wall of the manure ditch 8, the frame 1 includes two vertically arranged side plates 13, each of the side plates The lower sides of the 13 are provided with slide plates 11; two fixing frames 14 are fixed in parallel on the two opposite sides of the two side plates 13, and the two fixing frames 14 are fixed with a traction rod 12. The ends are respectively connected with traction ropes 121 . A first manure scraper 2, a water tank 3 and a second manure scraper 4 are sequentially arranged on two opposite side walls of the frame 1; the first manure scraper 2 includes a first manure baffle 21, and the A first scraper 22 is horizontally fixed on the lower edge of the first manure baffle 21; a water pipe 33 is arranged on the lower side of the water tank 3; The water inlet of the water pump 31 is connected t...

Embodiment 2

[0061] This embodiment is basically the same as the technical solution of the first embodiment, the difference is: refer to Figure 8 , the angle formed between the outer side of the first manure baffle 21 and the upper side of the first scraper 22 is 120 degrees.

[0062] When the breeding scale is large or the cleaning interval of the livestock and poultry manure cleaning device is long, the angle formed between the outer side of the first manure baffle 21 and the upper side of the first scraper 22 is 120 degrees, and the first manure baffle 21 The manure bucket formed with the first scraper 22 has a larger space, and at this time, this structure helps to increase the holding capacity of manure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com