Hot-rolling working roll temperature distribution obtaining method and device

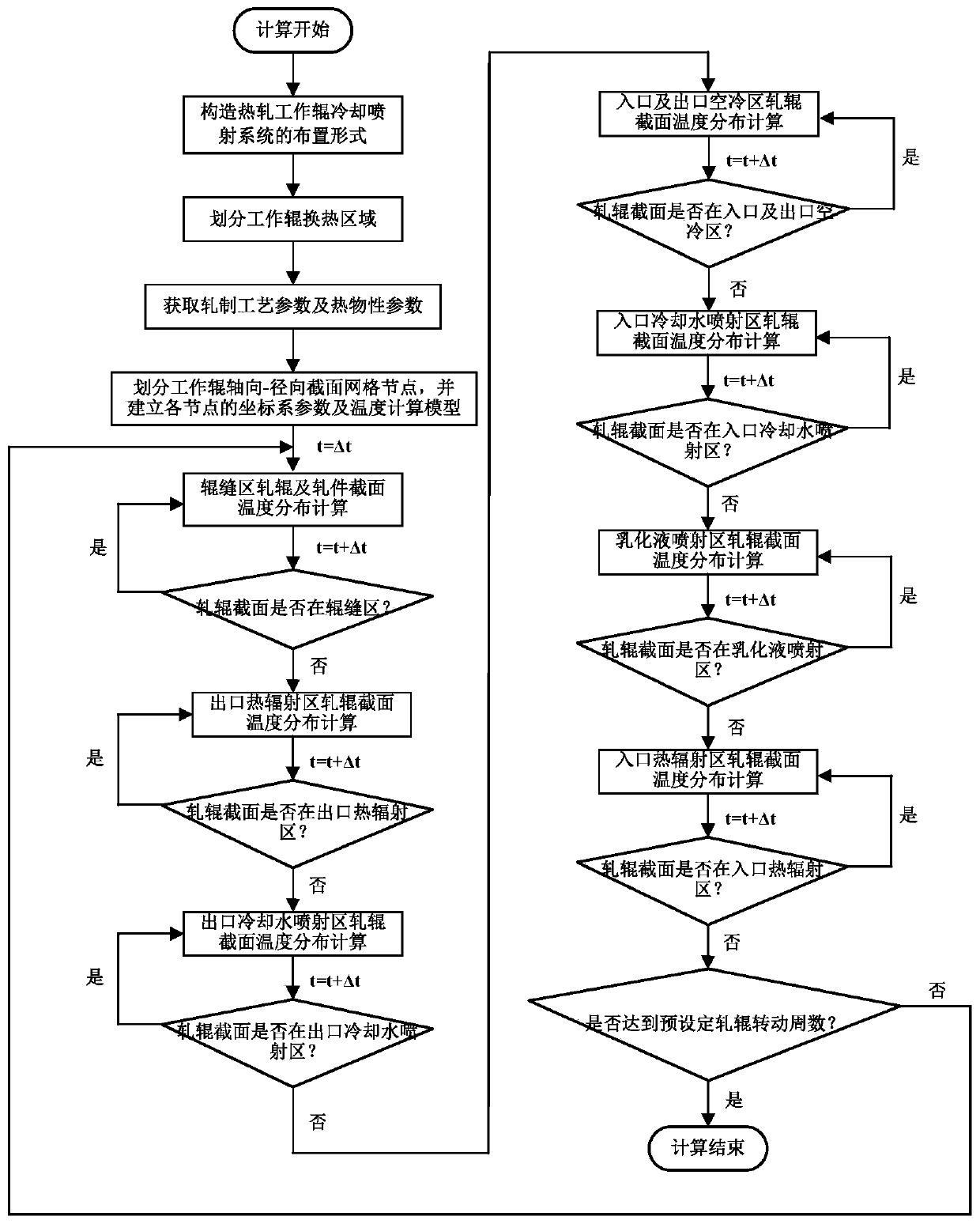

A temperature distribution and acquisition method technology, applied in the field of hot-rolled strips, can solve the problems of poor generality of temperature distribution models, inability to quickly and easily adapt to engineering calculation requirements, and low calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0128] In this example, on the basis of the method described in Example 1, the roll temperature distribution in a certain production process is further calculated, and compared with the measured value of the on-site roll temperature, to illustrate the versatility and accuracy of the method of the present invention.

[0129] figure 2 It is a schematic diagram of the work roll cooling injection system in this embodiment, including an inlet cooling water injection device 3 , an outlet cooling water injection device 4 , an inlet wiper blade 5 , an outlet wiper blade 6 and an inlet emulsion injection device 7 .

[0130] According to the arrangement position of each component of the above-mentioned work roll 2 cooling injection system, the roll heat exchange area is divided by the roll position angle, wherein the roll position angle is defined by the central angle relative to the center line of the roll, as shown in image 3 shown, respectively In addition, it can be known from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com