Test device for coupling complex atmosphere corrosion with high-temperature solid-phase erosion corrosion

A high-temperature solid-phase, erosion-corrosion technology, applied in the fields of weather resistance/light resistance/corrosion resistance, measuring devices, testing wear resistance, etc., can solve problems such as difficult to determine the cause of tube explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

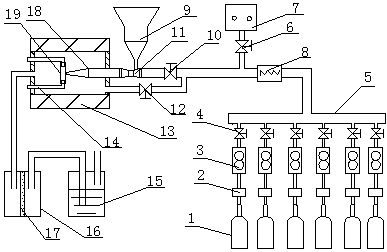

[0019] Example one, such as figure 1 , figure 2 with image 3 As shown, a complex atmosphere corrosion coupled high-temperature solid phase erosion corrosion test device includes a medium distribution system, a corrosion reaction system, and an exhaust gas treatment system; the medium distribution system includes a plurality of gas cylinders 1, a plurality of pressure reducing valves 2, Multiple mass flow meters 3, multiple one-way valves Ⅰ 4, gas mixer 5, one-way valve Ⅱ 6, steam generator 7, heater 8, steam generator model ZXYG38-A, multiple gas cylinders 1 are installed in sequence Have H 2 S, CO, CO 2 , HCl, O 2 , N 2 , SO 2 , NH 3 For gas, the outlet of heater 8 is directly connected to tube furnace 13 with one-way valve Ⅳ12 on the pipeline, and the other way is connected to tube furnace 13 through ejector 18, with one-way valve Ⅲ10 and venturi mixer on the pipeline. 11 and the feeder 9, the steam generator 7 is located at the outlet of the heater 8. The high-temperature g...

Embodiment 2

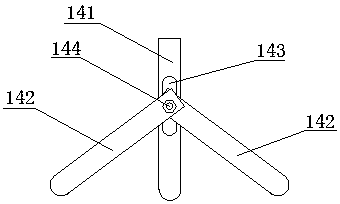

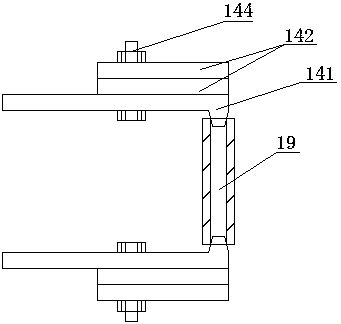

[0022] Example two, such as figure 1 , Figure 4 with Figure 5 As shown, the implementation of the medium distribution system and the exhaust gas treatment system in this embodiment is completely the same as that of the first embodiment, so it will not be repeated. The corrosion reaction system in this embodiment includes a tube furnace 13 and an ejector 18. A test piece support device 14 is provided at the exit of the ejector 18, and the test piece support device 14 fixes the test piece 19; the test piece support device 14 It includes a fixed clamp 141, a sliding clamp 142, an adjustment hole 143 and a fastening bolt 144. One end of the sliding clamp 142 is provided with a fixed hole. The specimen support device 14 includes at least two sliding clamps 142. The sliding clamp 142 and the fixed clamp are adjusted according to the experimental requirements. Adjust the position of the sliding clamp 142 in the adjustment hole 143 at the same time as the included angle between 141, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com